Understanding aluminium CNC service cost is essential for engineers, manufacturers, and product developers looking to create high-precision aluminium parts. CNC machining offers excellent accuracy, consistency, and fast production times, making it a go-to method for creating everything from prototypes to production parts. This guide will explore the factors that influence aluminium CNC service price, the role of aluminium CNC prototypes, how post-processing affects pricing, and tips for reducing costs while ensuring top-quality parts.

What Affects Aluminium CNC Service Cost?

Several factors contribute to the aluminium CNC service cost, including material type, part complexity, machining method, and additional services such as post-processing. Let’s break down these aspects to understand their impact on the final price.

Material Type and Alloy Selection

The type of aluminium alloy chosen for your project plays a significant role in the overall aluminium CNC service price. Alloys like 6061 aluminium are relatively easy to machine and are cost-effective, while alloys such as 7075 or 2024 are stronger but more difficult to machine, driving up costs. The material’s availability and its performance characteristics will also affect the price.

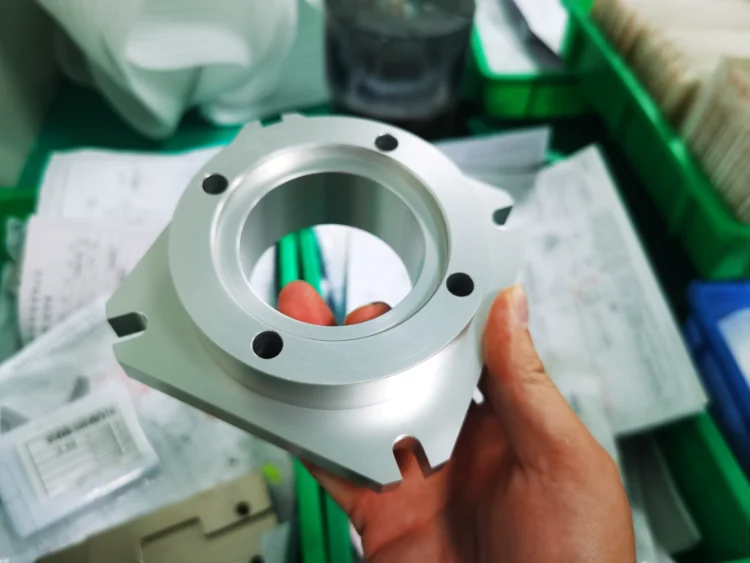

Part Complexity

Parts with intricate features, such as deep pockets, thin walls, or complex geometries, require more time and specialized tools to machine, which increases aluminium CNC service cost. More complex designs also mean additional setups and handling, adding to the price. Simpler geometries, on the other hand, can be processed more quickly, keeping costs lower.

Tolerances and Surface Finishes

Tight tolerances and special surface finishes increase aluminium CNC machining cost. For example, achieving ±0.01 mm tolerances or high-quality surface finishes like anodizing or polishing takes more time and requires high-end equipment. Parts with tighter tolerances or special finishes will naturally increase the machining time and cost.

The Impact of Post-Processing on CNC Aluminium Service Cost

While the machining process is the core of aluminium CNC service, post-processing adds an important layer of finishing that can affect the overall cost. Post-processing refers to any additional steps required to improve the surface quality, appearance, or functionality of the part after it has been machined. These processes include anodizing, polishing, deburring, and painting.

Anodizing and Surface Finishing

Anodizing is one of the most common post-processing methods for aluminium CNC service. It increases corrosion resistance and can be used for aesthetic purposes, providing a range of colors and textures. However, anodizing adds an additional cost due to the time required for preparation, the chemicals used, and the labor involved in the process.

For instance, anodized parts generally cost more than raw machined parts because of the extra steps involved. Similarly, polishing and fine finishing are often required for parts that need to meet specific industry standards, such as in aerospace or medical devices. These post-processing steps can add 20-30% to the cost of the part.

Deburring and Cleaning

Deburring is the process of removing sharp edges or burrs left over from the CNC machining process. While this is an essential part of quality control, it also increases the aluminium CNC service cost. Additional cleaning processes, such as ultrasonic cleaning, can further increase the price, especially if the parts are intended for sensitive applications where cleanliness is crucial (such as in the food or medical industries).

Painting and Coatings

Parts that require aesthetic finishes or extra protection, such as painting or coating, will also incur additional costs. These processes require specialized equipment, materials, and labor, all of which contribute to aluminium CNC service price. The choice of coating (e.g., powder coating, epoxy coating) can have a significant impact on the final price, especially if the coating needs to be thick or durable.

Aluminium CNC Prototypes: The Role of Prototyping in CNC Machining

Aluminium CNC prototypes are a crucial part of product development, allowing engineers and designers to test and validate designs before moving to full production. Prototyping with aluminium offers many benefits, including faster turnarounds and the ability to test the form, fit, and function of parts in real-world conditions.

Rapid Prototyping with Aluminium

Using aluminium CNC service for prototyping is a cost-effective way to evaluate your designs. The material’s machinability ensures quick turnaround times, especially with 6061 aluminium, which is ideal for rapid prototyping due to its excellent workability. Prototypes can be produced in days rather than weeks, providing valuable feedback on design and performance.

Cost-Effectiveness of Small Batches

One advantage of aluminium CNC prototyping is that small batches can be produced at a relatively low cost. While larger production runs offer economies of scale, prototyping allows for testing and adjustments with minimal investment. This makes it easier to make design changes and refine prototypes without committing to large-volume production runs.

Reducing Aluminium CNC Service Cost: Tips and Strategies

While aluminium CNC service offers high precision and performance, there are several strategies to help reduce costs without sacrificing quality.

Simplify Design and Geometries

Simplifying the design of your part can help reduce machining time and, ultimately, aluminium CNC service cost. Avoiding overly complex shapes, deep pockets, and intricate features can significantly cut down on the machining process. Using standard radii and avoiding unnecessary internal features will also help keep costs lower.

Use Standard Aluminium Alloys

Using common aluminium alloys like 6061 can reduce material costs and machining time. While more specialized alloys may offer improved strength or other benefits, they often require more complex machining processes that increase costs. For most applications, 6061 aluminium provides an excellent balance of performance and cost-effectiveness.

Increase Order Volume

Order volume plays a significant role in aluminium CNC service price. Larger batches reduce the per-part cost because setup costs, such as tool changes and machine adjustments, are spread over a greater number of parts. If you’re planning for mass production, working with a supplier who can handle high volumes may lead to significant savings.

Choosing the Right Aluminium CNC Service Provider

Choosing the right supplier for your aluminium CNC service is crucial to ensuring you get the best value and quality for your project. Here’s how to choose the best CNC machining partner:

Evaluate Machine Capabilities

Make sure the supplier has the necessary CNC machines and technologies to handle your part’s complexity. If your part requires multi-axis machining or high precision, choose a supplier that offers advanced aluminium CNC machining centres capable of handling those requirements.

Experience with Aluminium Alloys

Ensure the supplier has experience with the specific aluminium alloys you plan to use for your parts. A supplier familiar with the machining properties of different alloys will provide better results in terms of accuracy, surface finish, and part quality.

Lead Time and Communication

A reliable CNC machining partner should be able to meet your deadlines and communicate clearly throughout the project. Establishing clear timelines, understanding shipping requirements, and keeping the communication channels open are essential for a smooth process.

Aluminium CNC Service Pricing at Weldo Machining

At Weldo Machining, we offer competitive aluminium CNC service for both prototyping and production parts. Whether you need a prototype for a new product or require high-volume CNC machining, our team is here to provide quality parts with quick turnaround times. We specialize in aluminium CNC machining, offering precise milling, turning, and finishing services to meet your needs. Contact us today to get a detailed quote and discuss your project requirements.

FAQ of aluminium cnc service cost

What factors affect aluminium CNC service cost?

Material, part complexity, tolerances, surface finishes, and production volume all influence the cost of aluminium CNC machining.

How can I reduce aluminium CNC service cost?

Simplify your part design, use common aluminium alloys, and consider larger order volumes to lower unit costs.

How long does it take to produce aluminium CNC prototypes?

The production time for aluminium CNC prototypes typically ranges from a few days to a week, depending on part complexity and material requirements.