Brass CNC machining manufacturers play an essential role in supplying high-precision components for industries that require durability, conductivity, and excellent machinability. Businesses rely on brass CNC machining manufacturers to produce tight-tolerance parts used in electronics, plumbing, aerospace, industrial machinery, and automotive systems. As demand increases for stable and scalable production, companies also look for a reliable cnc machining brass parts supplier or a large-scale cnc machining brass parts factory capable of delivering mass-production quality.

Because brass is one of the most machine-friendly metals, its versatility has made it the preferred material for oem brass cnc machining projects. From connectors to complex micro-components, advanced cnc brass machining parts support high-performance products across global industries.

Why Brass CNC Machining Manufacturers Are in High Demand

Brass CNC machining manufacturers provide stable dimensions, excellent surface finishes, and fast machining speeds.

Brass produces clean chips and places minimal stress on tools, reducing production cost and improving efficiency.

This makes brass ideal for prototypes, mass production, and complex parts requiring multi-axis machining.

Modern industries require high accuracy, pushing manufacturers to adopt high-speed CNC milling, turning, and Swiss machining.

Common Brass Types Used by Brass CNC Machining Manufacturers

Professional brass CNC machining manufacturers typically work with a variety of brass grades designed for different mechanical and functional requirements.

C360 Brass (Free-Cutting Brass)

Known for the best machinability among copper alloys.

Ideal for high-volume turning and milling.

Used for fittings, connectors, screws, pins, and precision shafts.

Highly preferred by any cnc machining brass parts supplier.

C260 Brass (Cartridge Brass)

Stronger and more formable than C360.

Good for stamped or deep-drawn parts.

Used in decorative components, fuel system parts, and electrical terminals.

C464 Brass (Naval Brass)

Superior corrosion resistance in seawater environments.

Common for marine valves, pump shafts, and fluid equipment.

C280 Brass

Strong, ductile, and corrosion-resistant.

Used for industrial hardware and mechanical fittings.

These alloys influence tool paths, machining time, and final cost when working with brass CNC machining manufacturers.

U.S. Brass Standards Used in CNC Machining

The United States categorizes brass using the UNS (Unified Numbering System).

Understanding this classification helps companies choose materials for advanced cnc brass machining parts.

UNS C36000

Best for machining and high-speed production.

Widely used in connectors, gears, and valves.

UNS C26000

Stronger alloy, suitable for formed, machined, or polished components.

UNS C46400

Marine-grade brass with excellent durability.

UNS C28000

Used for structural and mechanical brass parts in industrial equipment.

European Brass Standards Used in CNC Machining

Europe uses EN standards to classify brass grades.

These grades are widely supported by any high-level cnc machining brass parts factory.

CW614N (Equivalent to C360)

Best machining performance.

Used for fast-turning mass production.

CW508L (Equivalent to C260)

Balanced mechanical strength and formability.

CW602N (DZR Brass)

Dezincification-resistant brass for water and heat systems.

CW721R (High-Strength Brass)

Used for heavy-load mechanical components.

Applications Supported by Brass CNC Machining Manufacturers

Brass CNC machining manufacturers supply precision components for multiple technical fields.

Electrical and Electronics

Brass is conductive and stable, ideal for terminals, sockets, contact pins, and connectors.

Electronics manufacturers rely on advanced cnc brass machining parts for consistent conductivity.

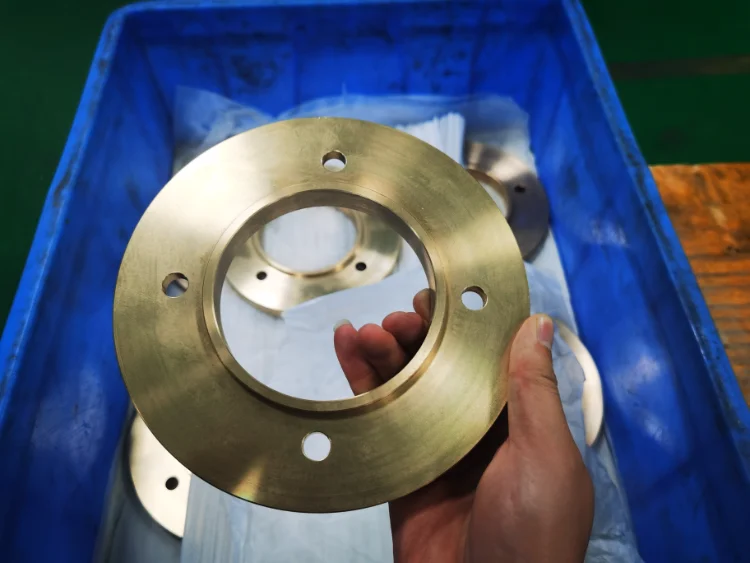

Plumbing and Fluid Systems

Brass fittings resist corrosion and mineral buildup.

Used in valves, nozzles, couplings, adaptors, faucets, and pump components.

Automotive and Machinery

Low friction and high precision make brass perfect for gears, bushings, transmission parts, and mechanical shafts.

Aerospace and Defense

Oem brass cnc machining supports sensor housings, pressure components, avionics hardware, and secure threaded inserts.

Aerospace requires high tolerance and certified materials.

Industrial and OEM Manufacturing

Factories producing custom machines rely on oem brass cnc machining for unique parts, brackets, connectors, and micro-components.

Surface Finishing Methods Offered by Brass CNC Machining Manufacturers

Finishing options improve aesthetics, corrosion resistance, and performance.

Polishing

Creates a bright, reflective surface ideal for decorative or visible components.

Electroplating (Nickel, Chrome, Gold)

Improves corrosion resistance and electrical performance.

Common in high-end electronics.

Sandblasting / Matte Finish

Provides a non-reflective finish used in mechanical and industrial parts.

Brushed Texture

Creates a directional grain for premium product appearance.

Clear Anti-Oxidation Treatment

Prevents tarnishing and stabilizes long-term color.

Surface finishing choice influences cost and lead time for brass CNC machining manufacturers.

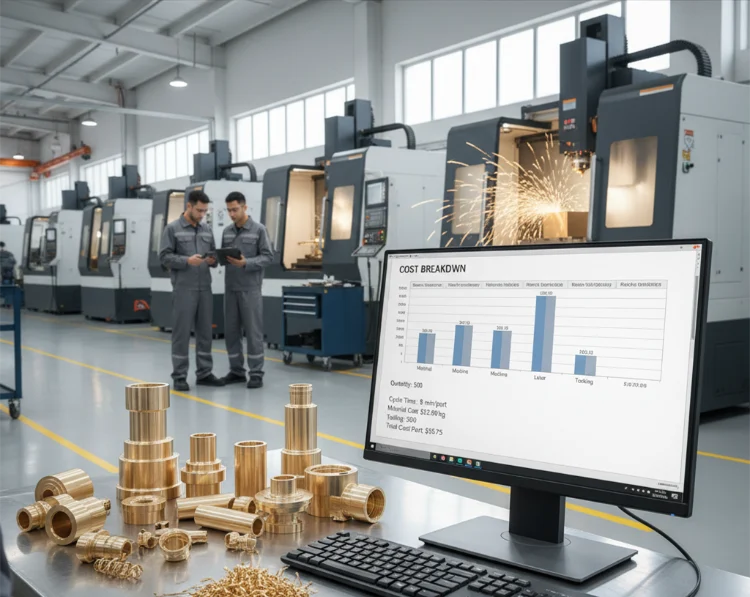

Why Choose a Professional CNC Machining Brass Parts Factory

A top-tier cnc machining brass parts factory provides stable production, engineering support, and consistent quality.

Strong Engineering Capabilities

Experts optimize design, reduce cost, and improve manufacturability.

Advanced Machinery

Including 5-axis mills, Swiss lathes, and high-speed turning centers.

Material Certification

Full compliance with UNS, ASTM, EN, and RoHS requirements.

Strict Quality Control

CMM inspection, hardness testing, surface checks, and tolerance validation.

A professional cnc machining brass parts supplier ensures part accuracy and long-term reliability.

Why Choose Weldo as Your Brass CNC Machining Manufacturer

Weldo specializes in supplying high-precision brass components to global customers.

We support C360, C260, C464, CW614N, CW508L, CW721R, and more.

Our team handles oem brass cnc machining, prototypes, mass production, and advanced cnc brass machining parts.

Weldo delivers stable tolerances, fast turnaround, and competitive pricing.

We provide polishing, plating, brushing, and multiple surface finishing services.

For companies seeking performance, reliability, and cost efficiency, Weldo is a trusted partner.

Conclusion

Brass CNC machining manufacturers provide essential components for electronics, plumbing, automotive, aerospace, and industrial sectors.

With various brass alloys—classified under U.S. UNS and EU EN standards—manufacturers can support multiple performance requirements.

Whether you need advanced cnc brass machining parts, custom OEM components, or high-volume supply, choosing the right cnc machining brass parts supplier is critical.

For accurate pricing, high precision, and engineering support, a professional factory ensures long-term success.

If you need custom quotes or cost analysis, Weldo is ready to help. Contact us today for more details about brass CNC machining solutions.

FAQ of brass cnc machining manufacturers

What do brass CNC machining manufacturers produce?

They produce precision brass parts for electronics, plumbing, machinery, automotive systems, and aerospace components.

Which brass grades are best for CNC machining?

C360/CW614N for machinability, C260/CW508L for formed parts, and C464/CW602N for corrosion-resistant applications.

Do manufacturers support custom or OEM brass parts?

Yes, oem brass cnc machining supports custom shapes, threads, tolerances, and surface finishes.

How do I reduce brass CNC machining cost?

Choose the correct alloy, simplify design, increase order quantity, and work with an experienced cnc machining brass parts factory like Weldo.

What industries use advanced CNC brass machining parts?

Electronics, aerospace, fluid control systems, robotics, automotive systems, and industrial equipment.