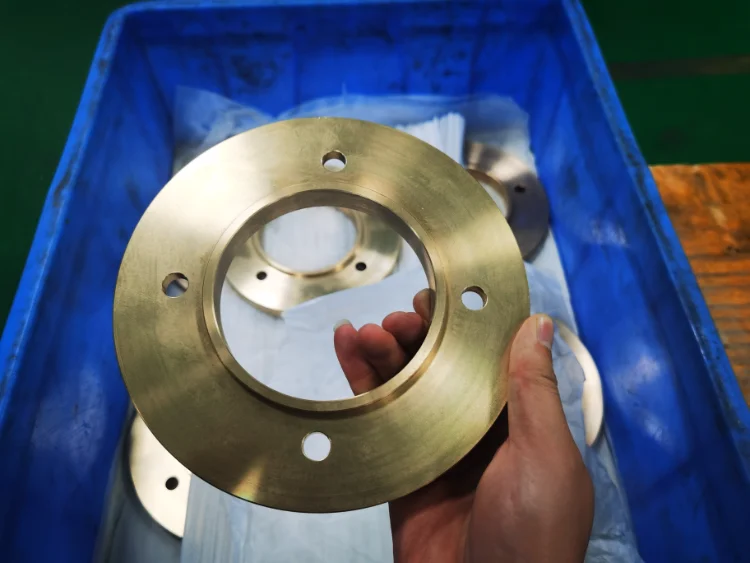

Brass CNC machining services are widely used in manufacturing industries that require high precision, smooth surface finishes, and excellent material stability. Brass is easy to machine, corrosion resistant, and electrically conductive, making it one of the most popular non-ferrous metals for CNC production. Companies rely on brass CNC machining services for connectors, fittings, gears, valves, electrical terminals, plumbing parts, and custom industrial components. As demand increases, more businesses require consistent quality for brass CNC machining parts, precision brass cnc machining, and oem brass cnc machining across multiple sectors. One of the most commonly used alloys is c360 brass cnc machining, known for its superior machinability.

Why Brass CNC Machining Services Are in High Demand

Brass CNC machining services offer strong dimensional accuracy and excellent repeatability.

Brass can withstand machining at high speeds without losing structural integrity.

It also produces clean chips, which improves tool life and reduces production cost.

These advantages make brass CNC machining services ideal for mass production and detailed custom components.

Types of Brass Used in CNC Machining

Different brass alloys support different performance requirements.

An experienced supplier of brass CNC machining services works with multiple grades.

C360 Brass

C360 is the most commonly used material for c360 brass cnc machining.

It features excellent machinability, ideal for threaded parts and high-volume production.

Its free-cutting properties reduce machining time and create smooth surfaces.

C260 Brass (Cartridge Brass)

Contains higher zinc content.

Offers strong formability and moderate machinability.

Used for deeper drawn components and decorative parts.

C280 Brass

A versatile alloy with good corrosion resistance.

Used for electrical terminals and connectors.

C464 Brass (Naval Brass)

High corrosion resistance for marine environments.

Used for seawater fittings, ship hardware, and pump components.

Characteristics That Make Brass Suitable for CNC Machining

Brass is preferred in CNC machining because of its excellent mechanical properties:

High machinability for fast cutting speeds.

Smooth surface finish ideal for visible components.

Anti-corrosion behavior in plumbing and fluid systems.

Good electrical and thermal conductivity for electronic components.

Low friction and wear resistance for gears and bushings.

These benefits support both mass production and precision brass cnc machining.

Key Applications of Brass CNC Machining Services

Brass CNC machining services support a wide range of industries.

Electronics and Electrical Components

Brass is conductive and stable.

Used for terminals, connectors, pins, sockets, and switches.

Precision brass cnc machining ensures reliable electrical performance.

Plumbing and Fluid Control

Brass fittings resist corrosion and mineral buildup.

Used in valves, nozzle fittings, adapters, and couplings.

Automotive and Mechanical Engineering

Brass gears, bushings, and transmission parts benefit from low friction.

Brass CNC machining parts maintain accuracy even under vibration.

Medical Devices

Non-magnetic and corrosion-resistant.

Used in small threaded components and sterile fittings.

Industrial and OEM Machinery

OEM manufacturers choose oem brass cnc machining for custom parts.

Supports prototypes and large production runs.

What Precision Brass CNC Machining Provides

Precision brass cnc machining offers high-tolerance machining for complex geometries.

CNC machines such as 3-axis, 4-axis, and 5-axis equipment allow detailed cutting, drilling, and threading.

Precision machining is critical when manufacturing sealing components, miniature connectors, and tight-fit assemblies.

This ensures functional stability and long service life.

Advantages of Working With an Experienced Brass CNC Machining Factory

A reliable supplier ensures material accuracy, stable production, and advanced equipment.

Professional Engineering Support

Engineers provide DFM guidance to improve manufacturability.

Helps reduce cost and improve performance.

Modern Equipment

CNC mills, lathes, Swiss machines, and 5-axis centers support complex brass components.

Quality and Inspection

Factories offering brass CNC machining services use CMM machines and precision gauges.

Inspection ensures every batch meets tolerance and performance standards.

Factors That Influence Brass CNC Machining Costs

Several factors impact pricing:

Material type (C360 is cheaper to machine).

Part complexity and tolerance requirements.

Surface finishing such as polishing, plating, or coating.

Production quantity (larger batches reduce cost).

Packaging and delivery requirements for small, fragile parts.

Understanding cost structure helps customers budget their brass CNC machining projects more effectively.

Customized Brass CNC Machining Services

Companies often request customized brass CNC machining parts to fit unique designs.

Applications include custom fittings, specialty threads, engraved components, and custom-shaped connectors.

OEM projects typically require drawings or 3D models to begin production.

Customized cnc machining phosphor bronze isn’t the focus here, but similar processes apply to brass.

Weldo provides custom machining services for prototypes and mass production.

Why Choose Weldo for Brass CNC Machining Services

Weldo specializes in high-quality brass CNC machining services across multiple industries.

We produce reliable brass CNC machining parts with tight tolerances and excellent surface finish.

Our experience covers c360 brass cnc machining, precision brass cnc machining, and complex OEM projects.

We support a wide range of custom geometries and high-volume orders.

Customers rely on Weldo for competitive pricing, engineering support, and stable mass-production capability.

Conclusion

Brass CNC machining services provide consistent quality, high precision, and long-lasting performance across multiple sectors.

With strong machinability, durability, and conductivity, brass remains one of the best materials for CNC machining.

Common alloys like C360, C260, C280, and C464 allow manufacturers to meet different application requirements.

Demand continues to grow for precision brass cnc machining, c360 brass cnc machining, and oem brass cnc machining.

Companies requiring custom shapes, connectors, fittings, and mechanical components benefit from the flexibility of brass CNC machining.

For accurate quotations and technical support, choosing the right supplier is essential.

If you need competitive pricing, engineering assistance, and reliable production, Weldo is ready to help.

Contact us today to learn more about brass CNC machining services and receive a customized quote.

FAQ of brass cnc machining services

What types of brass are most commonly used in CNC machining?

C360, C260, C280, and C464 are frequently used due to machinability and corrosion resistance.

What industries rely on brass CNC machining services?

Electronics, plumbing, automotive, medical, and general industrial OEM parts.

What affects brass machining cost?

Material grade, part complexity, surface finish, and production volume.

Do you offer customized or OEM brass CNC machining?

Yes. Weldo provides oem brass cnc machining and fully customized brass components based on drawings or 3D models.