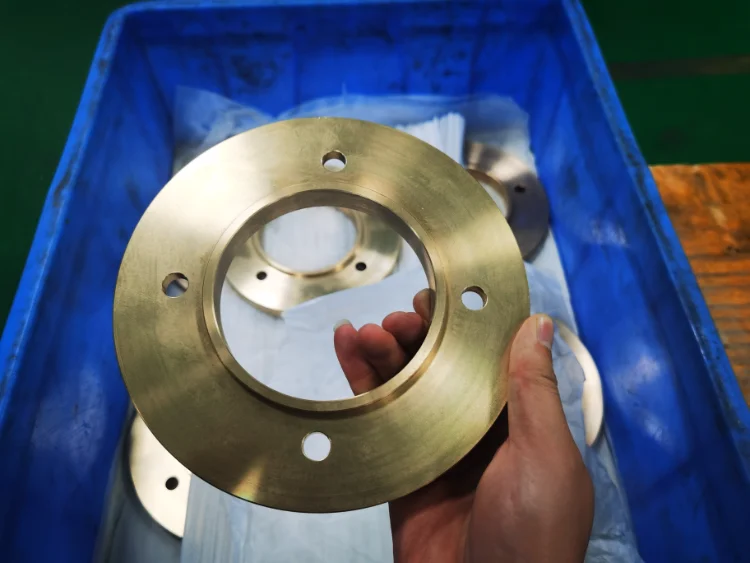

For industries requiring durable, wear-resistant, and dimensionally stable metal components, bulk bronze cnc machining has become one of the most reliable methods for large-scale production. Bronze is highly valued for its excellent machinability, mechanical strength, and natural corrosion resistance, making it suitable for both high-precision functional parts and industrial-grade mechanical assemblies.

Why Bulk Bronze CNC Machining Is Essential for High-Volume Production

As engineering projects continue to scale, the need for consistent, repeatable bronze components grows. Bulk bronze cnc machining offers stable performance in demanding environments, providing manufacturers with tight-tolerance parts ready for assembly or testing.

Benefits of Bulk Bronze CNC Machining for Industrial Use

- Cost-efficient production for large quantities

- Uniform quality across all machined components

- Stable metal properties suitable for heavy-load performance

- Fast turnaround with automated machining

- Compatibility with multi-axis CNC operations

A dependable bronze cnc machining supplier ensures every part maintains consistent tolerances and surface quality, even in bulk orders.

Common Alloys Used in Bulk Bronze CNC Machining

Different bronze alloys offer unique performance characteristics. Selecting the right material is critical when producing bronze cnc machining parts at scale.

1. C932 Bearing Bronze

Features

- Outstanding wear resistance

- Low-friction surface performance

- Easily machinable

Applications

- Bushings

- Bearings

- Sleeve components

- Rotational mechanical parts

A cost-effective alloy widely used in custom bronze cnc machining for industrial machinery.

2. C954 Aluminum Bronze

Features

- High strength and hardness

- Excellent corrosion resistance

- Superior stability under shock or heavy load

Applications

- Marine equipment

- Hydraulic components

- Heavy mechanical arms

- High-stress industrial assemblies

Ideal for bulk orders where performance and durability are critical.

3. C863 Manganese Bronze

Features

- Extreme hardness

- Exceptional impact resistance

- Resistant to deformation

Applications

- Gears

- Couplings

- Load-bearing prototypes

- Automotive bushings

Frequently used in bronze cnc machining service projects requiring rugged metal parts.

4. Phosphor Bronze (C510 / C544)

Features

- High fatigue resistance

- Good elasticity

- Stable under repetitive motion

Applications

- Electrical connectors

- Springs

- Precision sensor components

- Light-duty structural parts

Perfect for industries requiring both flexibility and strength.

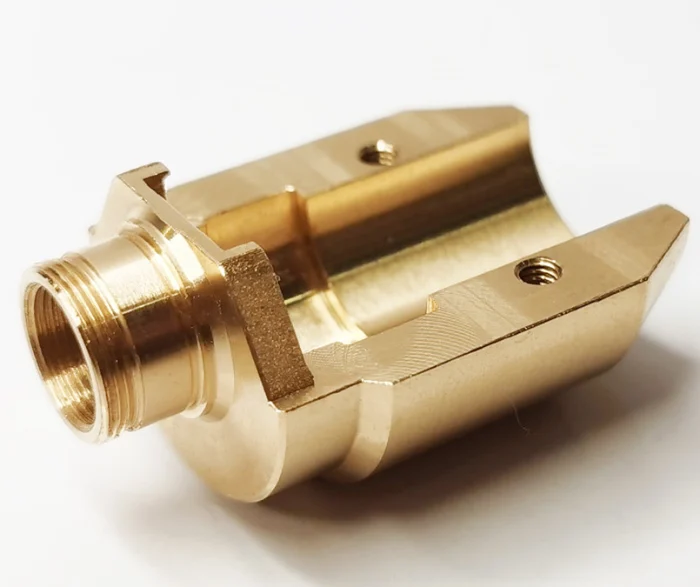

CNC Machining Techniques Used in Bulk Bronze Production

Bronze is highly machinable, allowing manufacturers to leverage advanced CNC techniques for large-scale production.

High-Volume Turning and Milling

Capabilities

- Consistent tolerances

- Smooth surface finishes

- Efficient multi-axis machining

- Suitable for long-run manufacturing

This is the foundation of most bulk bronze cnc machining projects.

Precision Drilling and Threading

Bronze’s structural strength supports:

- Internal and external threading

- Tight-tolerance hole drilling

- Threaded connectors

- Mechanical fastening elements

Essential for assemblies that require secure mechanical integration.

Surface Finishing for Bronze CNC Parts

High-volume bronze components often require standardized finishing:

- Polishing → smooth motion in mechanical systems

- Machined satin finish → stable aesthetics

- Passivation → improved corrosion resistance

- Oil impregnation → self-lubricating performance

These steps ensure long-term stability and consistency across large batches.

Applications of Bulk Bronze CNC Machining in Industry

Heavy Machinery and Industrial Equipment

- Bearings

- Gears

- Bushings

- Wear plates

Bulk bronze machined components are widely used in heavy-duty mechanical systems.

Automotive and Transportation

- Steering bushings

- Structural support parts

- Rotational components

Bronze provides excellent test reliability and long service life.

Marine and Offshore Equipment

- Corrosion-resistant hardware

- Pump components

- Propeller bushings

Aluminum bronze and manganese bronze are particularly suitable for marine environments.

Aerospace and Defense

- Load-bearing connectors

- High-strength sleeves

- Lightweight support mechanisms

Bronze components perform reliably under vibration, temperature changes, and mechanical stress.

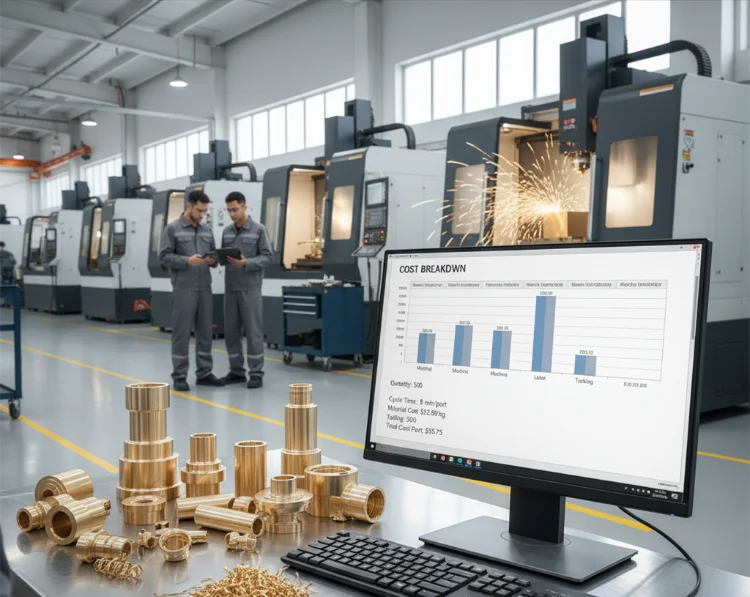

Advantages of Bulk Bronze CNC Machining for Businesses

High Cost Efficiency

Bulk production lowers unit cost while maintaining consistent precision.

Stable Mechanical Performance

Bronze components resist friction, stress, and deformation.

Ideal for Both Functional and Final Products

Bulk bronze machining supports both prototype testing and mass-market production.

Repeatable Accuracy

CNC automation ensures every batch meets the same engineering standards.

Broad Material Compatibility

Manufacturers can choose from multiple alloys to match performance goals.

Bulk Bronze CNC Machining Supplier Requirements

A reliable partner must ensure:

Strong CNC Capabilities

- Multi-axis machining

- Tight-tolerance control (±0.01–0.05 mm)

- Large-batch production capacity

Material Expertise

Understanding different bronze alloys is essential for performance-focused applications.

Quality Assurance

- Dimensional inspection

- Surface measuring

- Alloy certification

- Batch traceability

A trusted bronze cnc machining supplier guarantees stable quality from first piece to final delivery.

Request Bulk Bronze CNC Machining Quotes — Contact Weldo Machining

When looking for dependable high-volume machining, choosing the right partner is essential. As a professional provider of bulk bronze cnc machining, Weldo Machining offers multi-axis precision machining, strong material expertise, stable batch production, and advanced finishing capabilities. Whether you need bearing components, gears, sleeves, bushings, or custom structural parts, Weldo Machining delivers consistent precision, reliable engineering support, and competitive pricing for large-scale orders.

Contact Weldo Machining today to get accurate quotations and learn more about our bulk bronze CNC machining solutions.

FAQ of bulk bronze cnc machining

What is bulk bronze CNC machining used for?

It is used for large-volume production of bronze components such as bushings, gears, bearings, and mechanical fittings across multiple industries.

Why choose bronze for bulk CNC machining?

Bronze offers excellent wear resistance, corrosion protection, dimensional stability, and reliable performance under mechanical stress.

What industries rely on bronze CNC parts?

Industries include heavy machinery, automotive, aerospace, marine, robotics, and industrial automation.