Understanding the real carbon steel cnc machining price is essential for manufacturers and engineers who rely on durable, strong, and cost-effective metal parts. Carbon steel is widely used across automotive, machinery, industrial equipment, energy systems, and tooling because of its excellent strength, hardness, and machinability. However, the actual machining price depends on material grade, part complexity, tolerances, finishing, and production volume. This article breaks down each factor to help you plan your machining budget accurately.

Key Factors Affecting Carbon Steel CNC Machining Price

Different variables directly influence the carbon steel cnc machining price, and understanding these factors helps manufacturers optimize design, performance, and cost.

1. Carbon Steel Material Grades and Raw Material Cost

Choosing the correct material is one of the most important contributors to carbon steel cnc machining cost. Common grades include:

AISI 1018 (Low Carbon Steel)

- Excellent machinability

- Cost-effective

- Ideal for general-purpose parts

AISI 1045 (Medium Carbon Steel)

- Higher strength

- Good wear resistance

- Slightly higher machining difficulty

AISI 4140 (Alloyed Carbon Steel)

- Excellent toughness

- Heat-treatable

- Higher machining cost due to hardness

AISI 1215 (Free-Cutting Steel)

- Best machinability

- Lowest machining cost

- Ideal for high-volume production

Harder materials require slower cutting speeds, raising the carbon steel cnc machining price.

2. Machining Complexity and Geometry Requirements

Carbon steel parts vary widely in design. Complex geometries increase machining cost due to tool wear and longer production cycles.

Cost Drivers Include

- Deep cavities

- Thin-walled structures

- Complex 3D surfaces

- Tight internal radii

- Multi-axis machining

The more complex the geometry, the higher the carbon steel cnc machining cost.

3. Tolerance Requirements

Tight tolerances directly influence machining time.

Typical Tolerance Categories

- ±0.05 mm → Standard cost

- ±0.02 mm → Moderate cost increase

- ±0.005–0.01 mm → High precision, premium pricing

Carbon steel is stable and strong, but tight tolerances require extra inspection and slower cutting speeds, increasing the total carbon steel cnc machining price.

4. Batch Quantity and Production Scale

Production volume has a major impact on unit price.

Price Trend Overview

| Quantity | Cost Effect |

|---|---|

| 1–10 pcs | Highest unit cost |

| 10–50 pcs | Moderate reduction |

| 50–500 pcs | Best price per unit |

Higher volumes dilute setup time and reduce per-unit carbon steel cnc machining cost.

5. Surface Finishing Requirements (Very Important for Cost)

Carbon steel requires surface finishing to prevent oxidation and improve durability. Different finishing options contribute differently to the total carbon steel cnc machining price.

Common Surface Finishing Options for Carbon Steel CNC Machining

Finishing improves corrosion resistance, appearance, and surface hardness. Below are the most commonly used options:

Black Oxide

Features

- Economical

- Deep black finish

- Moderate corrosion resistance

Uses

- Tools

- Machinery fittings

- Fasteners

Zinc Plating

Features

- Excellent rust protection

- Available in clear, yellow, or black zinc

- Ideal for outdoor or humid environments

Uses

- Automotive components

- Construction hardware

Powder Coating

Features

- Thick, durable protective film

- Strong impact resistance

- Long-lasting color options

Uses

- Mechanical housing parts

- Structural steel brackets

Heat Treatment (Quenching & Tempering)

Features

- Increases hardness

- Enhances wear resistance

- Improves tensile strength

Uses

- Gears

- Shafts

- Load-bearing components

Heat treatment often raises carbon steel cnc machining cost because of added processing steps.

Machined Finish (As-Milled)

Features

- No added cost

- Functional surface

- Ideal for internal or non-visible components

This is the most economical option when surface appearance is not critical.

Typical Price Range for Carbon Steel CNC Machining

While pricing varies depending on complexity and finish, typical ranges include:

| Part Type | Carbon Steel CNC Price Range |

|---|---|

| Simple blocks | $20–$60 |

| Shafts, pins | $30–$90 |

| Mounting brackets | $40–$120 |

| Gears, bushings | $80–$200 |

| Precision mechanical parts | $120–$300+ |

Actual carbon steel cnc machining price depends on tolerances, finishing, and design complexity.

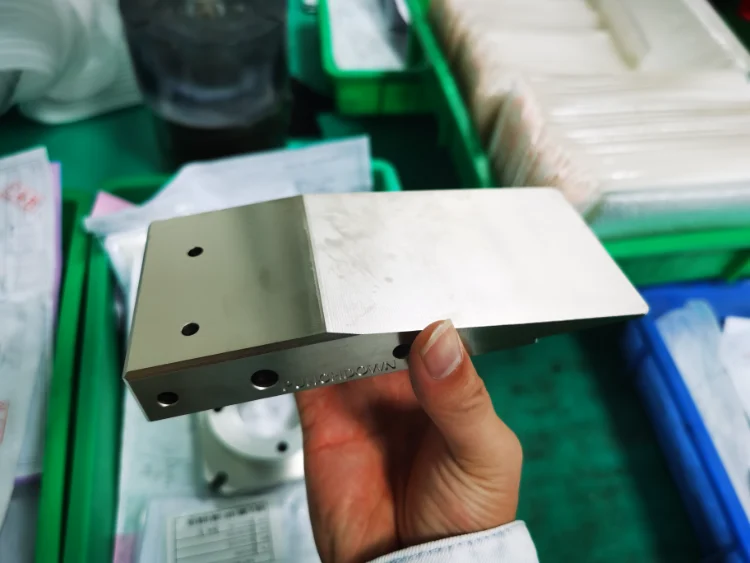

Material Options for Carbon Steel CNC Machining

Each grade has different performance and cost benefits.

AISI 1018

Applications

- Mechanical housings

- Fixtures

- Machined plates

AISI 1045

Applications

- High-load shafts

- Wear-resistant components

- Automotive parts

AISI 4140

Applications

- Structural machinery parts

- Oil & gas equipment

- Heavy-duty industrial components

AISI 1215

Applications

- Fasteners

- Bushings

- High-volume precision parts

Low machining cost makes it ideal for mass production.

Applications of Carbon Steel CNC Machining

Carbon steel is one of the most versatile engineering materials. Industries rely on CNC-machined carbon steel parts for strength, durability, and affordability.

Automotive Industry

- Shafts

- Gears

- Structural brackets

- Suspension components

Industrial Machinery

- Tooling components

- Machine frames

- Power transmission parts

Construction & Heavy Equipment

- Support structures

- Couplings

- Reinforcement hardware

Robotics and Automation

- Mounting plates

- Servo motor brackets

- Wear-resistant mechanical parts

Many of these components require specific finishes, which influence the final carbon steel cnc machining cost.

How to Reduce Carbon Steel CNC Machining Price

Choose Machinable Grades

1018 and 1215 reduce machining time.

Avoid Unnecessary Tight Tolerances

Standard tolerances save cost without affecting functionality.

Optimize Part Geometry

Simplifying the design lowers tool wear and machining time.

Select Cost-Effective Finishing

Black oxide or as-milled finishes can control expenses.

Request Carbon Steel CNC Machining Price — Contact Weldo Machining

To achieve the best balance of cost, precision, and performance, choosing an experienced machining partner is essential. As a reliable supplier of precision metal components, Weldo Machining offers competitive carbon steel cnc machining price solutions with multi-grade material options, advanced CNC capabilities, and a full range of surface finishing services. Whether you need prototypes or mass production, our team delivers consistent quality and fast turnaround.

Contact us today for accurate pricing, engineering feedback, and detailed quotations for your carbon steel CNC machining needs.

FAQ of Carbon Steel CNC Machining Price

What factors affect carbon steel CNC machining price?

Material grade, tolerances, finishing, batch size, and machining complexity are the main cost contributors.

Which carbon steel grade is cheapest to machine?

AISI 1215 is the most machinable and typically offers the lowest machining cost.

Does finishing increase carbon steel CNC machining cost?

Yes—coatings such as black oxide, zinc plating, and powder coating add processing time and cost.

Is carbon steel more expensive to machine than stainless steel?

No. Carbon steel is generally easier to machine and often costs less than stainless steel CNC machining.