Understanding cnc aluminium prototyping cost is essential for engineers, product developers, and buyers who need fast, accurate, and reliable prototype parts made from aluminium. CNC prototyping offers unmatched dimensional precision and excellent strength-to-weight performance, making aluminium one of the most preferred materials for early-stage design validation. This guide explains the key factors influencing cost, recommended aluminium grades, machining requirements, and how to optimize your prototype budget while maintaining quality.

What Affects CNC Aluminium Prototyping Cost?

The cnc aluminium prototyping cost is determined by material selection, machining complexity, tolerance requirements, surface finishing, and the overall quantity of prototypes. Since CNC prototyping involves multiple setups, programming time, and machine hours, understanding how these costs form enables you to estimate budgets more accurately. Prototype pricing also varies based on machine capability and the efficiency of the shop producing the parts.

Aluminium Materials Commonly Used for CNC Prototyping

Material choice is one of the biggest contributors to cnc aluminium prototyping cost. Different alloys balance strength, machinability, corrosion resistance, and thermal performance.

6061 Aluminium

- Most economical and widely machined alloy

- Good machinability and strong structural performance

- Low cost → Reduces cnc aluminium prototyping cost

7075 Aluminium

- High-strength aluminium, often used in aerospace and motorsport

- More difficult to machine → Higher tool wear

- Increases prototyping cost

5052 / 6082 Aluminium

- Improved corrosion resistance

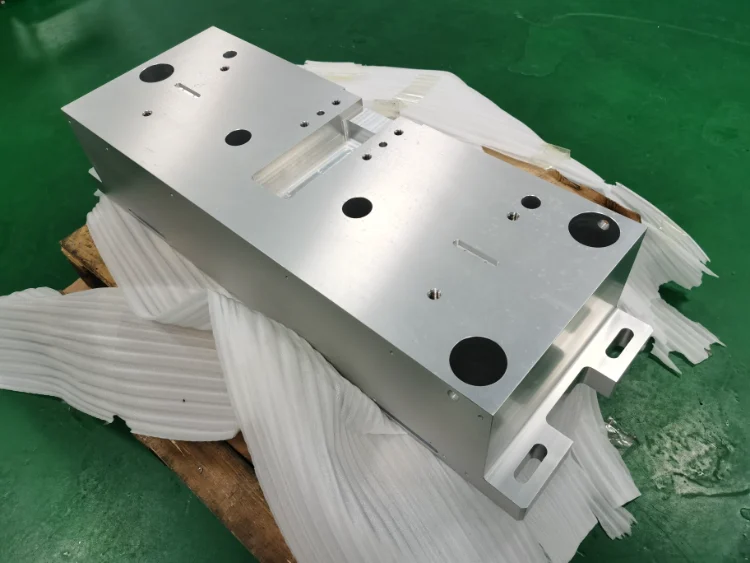

- Common for marine, enclosure, and structural frame prototypes

- Moderate pricing

Choosing the most suitable grade can significantly influence the overall cnc aluminium prototyping cost, especially when producing multi-piece prototype sets.

Machining Factors That Influence Prototype Pricing

Part Geometry Complexity

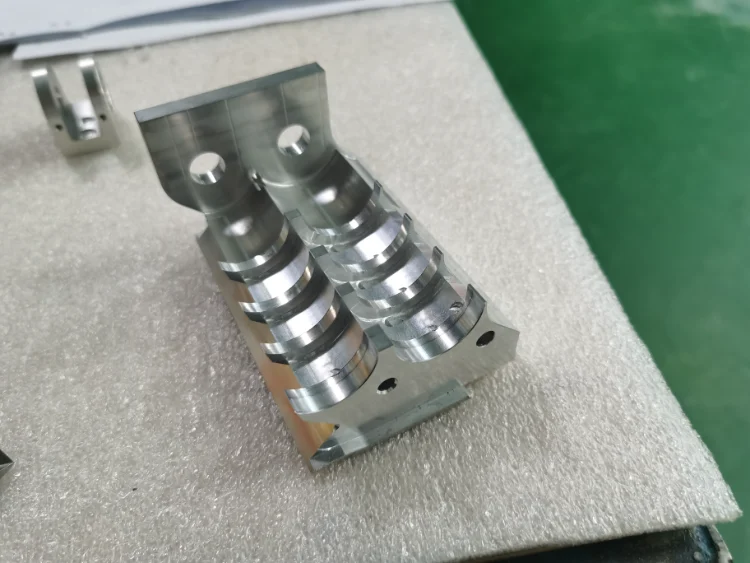

Deep pockets, thin walls, internal channels, and 5-axis features require more time and setups.

→ More machining hours = Higher cnc aluminium prototyping cost

Tolerance Requirements

- Standard tolerances: ±0.05 mm

- High-precision tolerances: ±0.01–0.02 mm

Tighter tolerances demand slower cutting speeds, high-end tools, and additional inspection procedures.

Surface Finish and Post-Processing

Options include:

- Sandblasting

- Brushed finish

- Chromate conversion

- Hard anodizing

- Color anodizing

Advanced surfaces add measurable cost to CNC aluminium prototyping due to extra preparation and process cycles.

Quantity vs. CNC Aluminium Prototyping Cost

Unlike mass production, prototyping is heavily influenced by setup time. The first unit is usually the most expensive.

Single Prototypes

- Highest unit cost

- Includes programming + fixturing setup

Small Batch Prototyping

Producing 5–30 units dramatically reduces per-piece price because setup cost is divided across multiple parts.

Bridge Production

Used when preparing for injection molding or mass CNC production.

Provides realistic testing parts while still optimizing unit cost before large-scale rollout.

CNC Equipment and Its Impact on Prototype Pricing

Shops using advanced multi-axis machines often produce better prototypes faster. Machine capability has a direct effect on cnc aluminium prototyping cost.

3-Axis Machining

- Most economical

- Suitable for basic pockets, cuts, and 2.5D geometries

4-Axis Machining

- Enables faster machining around cylindrical features

- Reduces setups

- Helps lower overall cost for medium-complex parts

5-Axis Machining

- Ideal for complex prototypes

- Highest precision and best surface finish

- Higher cost due to advanced tooling and equipment requirements

Matching your prototype complexity with the correct CNC configuration is essential for efficient spending.

Strategies to Reduce CNC Aluminium Prototyping Cost

Simplify CAD Geometry

Avoid unnecessary ribs, ultra-thin walls, and over-tight tolerances. These features increase cost dramatically.

Use Standard Fillet Radii

Internal radii that match common tool diameters reduce machining time.

Choose the Right Alloy

6061 is usually the most cost-efficient option for prototypes.

Order Small Batches Instead of Single Units

Spreading setup cost over multiple pieces reduces unit pricing.

Select Cost-Friendly Surface Finishes

Simple anodizing or blasting is more economical than complex multi-stage coatings.

Applying these guidelines can lower the total cnc aluminium prototyping cost without sacrificing function or accuracy.

Why CNC Aluminium Prototyping is Ideal for Engineering Validation

Aluminium prototypes offer several advantages over 3D printing, casting, and plastic models:

High Strength-to-Weight Performance

Realistic structural performance suitable for mechanical testing.

Excellent Dimensional Accuracy

CNC machining provides precise fits for assemblies and functional testing.

Thermal Conductivity

Ideal for heatsinks, housings, brackets, and high-temperature tests.

Superior Surface Quality

Machined aluminium finishes create production-ready prototype surfaces.

These benefits make aluminium CNC prototyping a preferred solution in electronics, robotics, automotive, aerospace, industrial automation, consumer products, and mechanical engineering.

Choosing the Right Supplier for CNC Aluminium Prototyping

Selecting the correct machining partner can save time, cost, and avoid engineering delays.

Look for Multi-Axis Capability

Shops with 3-axis, 4-axis, and 5-axis options can match the complexity of your prototype efficiently.

Confirm Tolerance Expertise

Ask for previous examples of ±0.02 mm or high-precision prototype work.

Check Communication & DFM Support

Good suppliers offer manufacturability improvements that reduce cnc aluminium prototyping cost.

Review Material & Surface Treatment Options

A complete shop handles anodizing, blasting, and chromate work in-house or through trusted partners.

Work With Weldo Machining for CNC Aluminium Prototyping Cost Solutions

When you need precision prototypes, fast engineering iterations, and reliable small-batch production, Weldo Machining provides professional CNC aluminium prototyping with competitive pricing and excellent tolerances. Whether you’re producing a single functional part or preparing for mass production, our team can offer accurate quotes, material suggestions, and efficient cost-saving solutions. Contact us for more details about your project and to obtain customized estimates for cnc aluminium prototyping cost.

FAQ of cnc aluminium prototyping cost

What determines cnc aluminium prototyping cost?

Material grade, part complexity, tolerances, surface finishing, and quantity all influence the final cost.

Which aluminium alloy is cheapest for CNC prototypes?

6061 aluminium is usually the most economical and widely used option.

Does 5-axis machining increase prototype cost?

Yes, 5-axis machining is more expensive but necessary for complex geometries requiring multi-face access.

How can I lower CNC aluminium prototyping cost?

Simplify geometry, relax tolerances, choose 6061 aluminium, and order small batches instead of single units.

How do I get an accurate quote?

Provide 2D/3D drawings, quantities, tolerances, materials, and finishing requirements for a precise pricing estimate.