In modern manufacturing, CNC aluminum machining has become one of the most widely used and reliable production methods for precision parts. Thanks to aluminum’s excellent balance of light weight, high strength, corrosion resistance, and machinability, aluminum CNC parts are used across a wide range of industries.

With increasing demands for precision, consistency, and fast delivery, CNC aluminum machining is now the preferred solution for both prototyping and production.

What Is CNC Aluminum Machining?

CNC Aluminum refers to the process of using CNC (Computer Numerical Control) machines to manufacture parts from aluminum and aluminum alloys with high precision and repeatability.

Compared with conventional machining, CNC aluminum machining offers:

- High dimensional accuracy

- Excellent repeatability

- Ability to machine complex geometries

- Stable quality for both small and medium batch production

- Fast transition from design to finished parts

Why Aluminum Is Ideal for CNC Machining

Aluminum is one of the most CNC-friendly metals. Its physical and mechanical properties make it especially suitable for high-efficiency and high-precision machining.

| Property | Benefit in CNC Machining |

|---|---|

| Low density | Ideal for lightweight design |

| Excellent machinability | Faster cutting speed, lower cost |

| Good thermal conductivity | Better surface finish, less tool wear |

| Corrosion resistance | Suitable for many environments |

| Wide range of alloys | Can meet different strength and performance needs |

Because of these advantages, CNC aluminum machining is usually more cost-effective and efficient than machining stainless steel or titanium.

Aluminum Grades We Machine

We offer CNC aluminum machining services covering a full range of commonly used and high-performance aluminum alloys, including but not limited to:

6061, 6063, 7075, 2024, 5052, 5083, 6082, and MIC-6.

We also support custom aluminum grades based on customer requirements.

Common Aluminum Grades and Their Characteristics

6061 Aluminum

6061 aluminum is the most widely used material in CNC aluminum machining due to its excellent balance of strength, machinability, and corrosion resistance. It is easy to machine, stable during cutting, and ideal for both prototypes and production parts.

6063 Aluminum

6063 aluminum is a popular choice for CNC aluminum machining due to its smooth surface finish and good processing stability. It is often used for decorative parts and components with high appearance requirements.

7075 Aluminum

7075 aluminum is one of the highest-strength aluminum alloys commonly used in CNC machining, with mechanical strength close to steel. It is ideal for high-load and high-stress parts, but requires more careful machining compared to standard aluminum grades.

2024 Aluminum

2024 aluminum is a high-strength aluminum alloy widely used in CNC machining for parts that require excellent fatigue resistance. It is commonly applied in aerospace and high-stress mechanical components, but usually needs surface protection due to its lower corrosion resistance.

5052 Aluminum

5052 aluminum is a popular choice in CNC machining for housings and structural parts with moderate strength requirements. Its excellent corrosion resistance makes it suitable for outdoor and marine-related applications.

5083 Aluminum

5083 aluminum is a high-strength, marine-grade aluminum alloy commonly used in CNC machining for parts that require excellent corrosion resistance. It performs especially well in seawater and harsh environments and is ideal for marine and heavy-duty structural components.

6082 Aluminum

6082 aluminum is a high-strength structural aluminum alloy commonly used in CNC machining for load-bearing parts. It offers good machinability and corrosion resistance, and is often considered a stronger alternative to 6061 in structural applications.

MIC-6 Aluminum

MIC-6 aluminum is a cast aluminum tooling plate widely used in CNC machining for applications that require excellent flatness and dimensional stability. Its low internal stress and stable structure make it ideal for jigs, fixtures, and precision base plates.

What Is the Toughest Aluminum?

In most engineering and CNC machining applications, 7075 aluminum is widely considered the toughest and strongest commonly used aluminum alloy. It offers extremely high tensile strength and yield strength, comparable to some steels, while still maintaining the lightweight advantage of aluminum.

Because of its excellent strength-to-weight ratio, fatigue resistance, and mechanical performance, 7075 aluminum is commonly used in aerospace, high-performance mechanical parts, molds, and high-load structural components. However, it is more difficult and expensive to machine compared to standard grades like 6061.

A ranking of aluminum alloys used in CNC machining, from strongest to weakest.

7075 > 2024 > 6082 > 6061 > 5083 > 5052 > 6063 > MIC-6

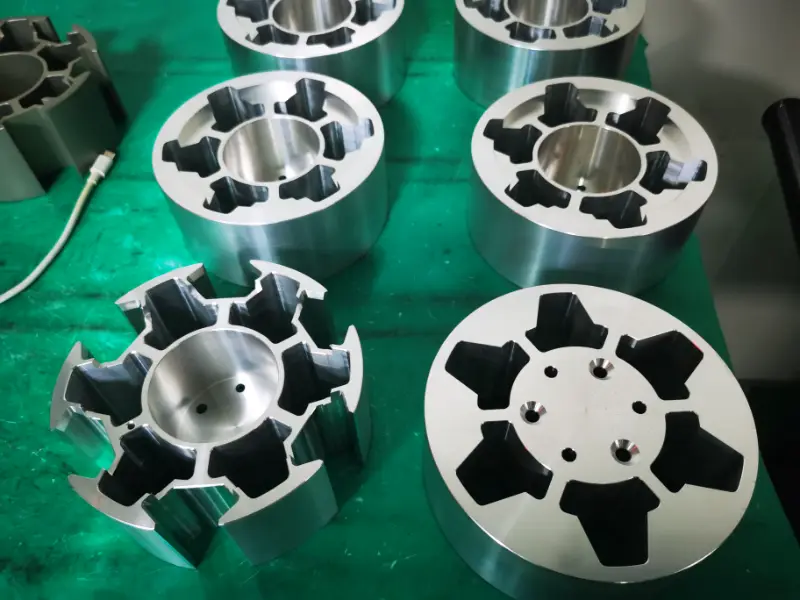

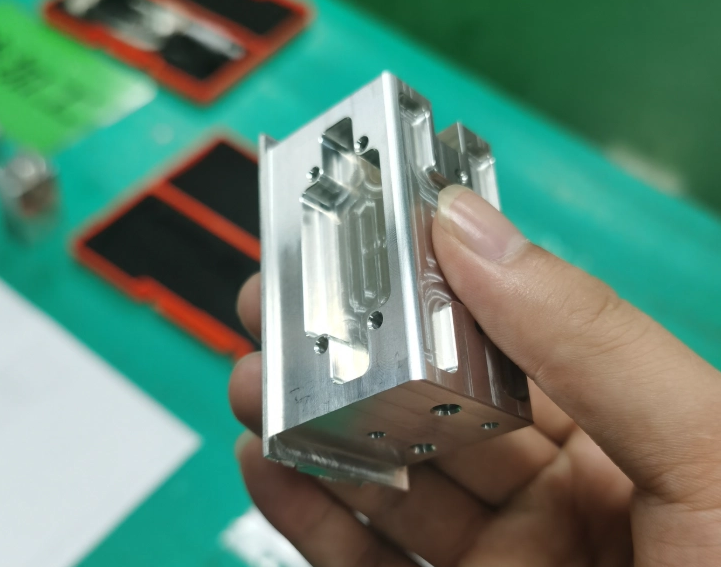

CNC Aluminum Machining Processes

Our CNC aluminum machining capabilities include:

- 3-axis, 4-axis, and 5-axis CNC milling for complex geometries

- CNC turning for rotational parts

- Mill-turn machining for higher efficiency

- Drilling and tapping for assembly features

- Precision finishing for tight tolerances

- Secondary operations such as deburring and chamfering

Typical tolerance capability:

- Standard tolerance: ±0.1 mm

- Precision tolerance: ±0.01 ~ ±0.02 mm

- Ultra-precision (with secondary processes): ±0.005 mm

Surface Finishing for CNC Aluminum Parts

To improve appearance, durability, and functional performance, CNC aluminum parts can be finished in many ways.

- Anodizing – it forms a protective oxide layer on the aluminum surface, significantly improving corrosion resistance and wear resistance. It also enhances appearance and is widely used for both functional and decorative parts.

- Hard Anodizing – it creates a much thicker and harder oxide layer compared to standard anodizing. It is ideal for parts that require high surface hardness, wear resistance, and long service life.

- Sandblasting – Sandblasting creates a uniform matte surface and improves surface texture consistency. It is often used as a pre-treatment before anodizing, painting, or coating.

- Brushing – Brushing produces a consistent linear texture on the surface, mainly for aesthetic purposes. It is commonly used for appearance parts where visual quality is important.

- Powder Coating – Powder coating adds a thick and durable protective layer to the aluminum surface. It provides excellent corrosion resistance, impact resistance, and a wide range of color options.

- Plating – Plating applies a thin metal layer to improve corrosion resistance, conductivity, or specific functional properties. Different plating materials can be selected depending on the performance requirements.

- Painting – Painting is mainly used for decorative purposes and basic surface protection. It offers flexible color options and is suitable for parts that do not require high wear resistance.

Anodizing is one of the most popular surface treatments because it enhances both corrosion resistance and surface hardness.

Is CNC Aluminum Expensive?

Many customers ask: Is CNC aluminum machining expensive? The short answer is: it depends, but compared with many other metals, aluminum is actually one of the most cost-effective CNC machining materials.

In general, CNC aluminum is affordable because:

- Aluminum is easy to machine, which reduces machining time and labor cost.

- Material cost is relatively low, especially for common grades like 6061 and 6063.

- High machining efficiency means lower machine-hour cost.

- Lower tool wear helps reduce tooling and maintenance cost.

However, CNC aluminum machining can become more expensive if:

- The part requires very tight tolerances

- The geometry is complex

- The material is high-strength aluminum such as 7075

- The part requires special surface treatments or full inspection

In most applications, CNC aluminum offers one of the best cost-to-performance ratios among all metal materials.

What Determines the Cost of CNC Aluminum Machining?

The cost is influenced by several technical and production factors:

- Material grade – High-strength or special alloys cost more and are harder to machine.

- Part complexity – Complex shapes require more machining time and setups.

- Tolerance requirements – Tighter tolerances mean slower cutting and more inspection.

- Surface finishing – Additional processes add extra cost.

- Order quantity – Small batches have higher unit cost.

- Inspection standards – CMM or full inspection increases labor and time cost.

In general, higher precision, higher complexity, and higher quality requirements mean higher cost.

Is CNC Aluminum Stronger Than Cast Aluminum?

In most cases, CNC-machined aluminum parts are stronger than cast aluminum parts. This is because CNC parts are usually made from wrought aluminum alloys (such as 6061, 7075, or 6082), which have a denser and more uniform internal structure compared to cast aluminum.

Cast aluminum may contain porosity and internal defects, which reduce mechanical strength, while CNC-machined aluminum from solid billet offers better strength, better fatigue resistance, and more consistent mechanical performance.

| Item | CNC Aluminum (Billet / Plate / Bar) | Cast Aluminum |

|---|---|---|

| Internal Structure | Dense and uniform | May contain porosity |

| Strength | Higher | Lower |

| Fatigue Performance | Better | Poorer |

| Stability | More stable | More likely to have defects |

| Typical Applications | Structural and load-bearing parts | Appearance parts and non-critical components |

Does CNC Aluminum Rust?

The short answer is: no, CNC aluminum does not rust like steel. Rust is a form of iron oxidation, and aluminum does not contain iron, so it cannot rust in the traditional sense.

However, aluminum can still corrode in certain environments. When exposed to air, aluminum naturally forms a thin oxide layer on the surface, which actually protects the material from further corrosion. This is why aluminum has much better natural corrosion resistance than steel.

In harsh environments such as marine, chemical, or outdoor applications, aluminum parts are often treated with anodizing or other surface finishes to further improve corrosion resistance and durability.

The Future of CNC Aluminum Machining

CNC aluminum machining will continue to grow because:

- Lightweight design is a global trend

- Automation and robotics are expanding

- New energy and electronics industries are growing

- Aluminum offers excellent cost-to-performance value

CNC aluminum machining will remain a core manufacturing technology for many years to come.

Conclusion

CNC aluminum machining combines the excellent properties of aluminum alloys with the precision, consistency, and efficiency of modern CNC technology, making it one of the most important manufacturing methods in today’s industry. From material selection and machining processes to surface finishing and cost control, choosing the right approach directly determines product quality and performance. With a wide range of aluminum grades available, each project can be optimized for strength, weight, durability, and budget. A professional CNC aluminum supplier not only produces parts, but also helps optimize design and manufacturing strategy. Choosing the right partner is the key to achieving reliable quality, stable cost, and long-term success.