In today’s precision-driven manufacturing market, selecting a reliable cnc custom machining manufacturer is a critical decision that directly impacts product quality, cost control, and delivery timelines. Whether you are sourcing prototypes or high-volume production parts, understanding how a professional CNC machining factory operates will help you identify the right supplier for long-term success.

What Defines a CNC Custom Machining Manufacturer

A cnc custom machining manufacturer is more than a basic parts supplier. It is a specialized factory that converts digital designs into high-precision components using advanced CNC milling, turning, and multi-axis machining processes. Unlike standard machining shops, a true custom manufacturer focuses on:

- Customer-specific drawings and tolerances

- Flexible production volumes

- Engineering support and manufacturability optimization

- Consistent quality across batches

A professional CNC machining supplier typically serves industries such as aerospace, medical devices, automotive, robotics, electronics, and industrial equipment, where precision and repeatability are essential.

Core Capabilities of a CNC Custom Machining Factory

When evaluating a cnc custom machining manufacturer, machining capability is the first technical factor to review. A qualified supplier should support multiple CNC processes to handle complex geometries and tight tolerances.

CNC Machining Processes Offered

Most advanced CNC machining factories provide:

- 3-axis CNC milling for standard prismatic parts

- 4-axis and 5-axis CNC machining for complex contours and multi-face parts

- CNC turning for shafts, bushings, and rotational components

- Mill-turn machining for reduced setups and higher accuracy

- Prototype machining and low-volume production

- Medium to high-volume CNC production machining

A capable cnc custom machining manufacturer should be able to hold tolerances as tight as ±0.001 inch (±0.025 mm) depending on material and geometry.

Material Machining Capabilities You Should Expect

Material versatility is a key indicator of a strong CNC machining supplier. A reliable cnc custom machining manufacturer should process both metals and engineering plastics to meet diverse application needs.

Common Metal Materials

- Aluminum alloys (6061, 7075, 2024)

- Stainless steel (303, 304, 316, 17-4PH)

- Carbon steel and alloy steel

- Brass and copper alloys

- Titanium (Grade 2, Grade 5)

Engineering Plastics

- PEEK

- PTFE

- POM (Delrin)

- Nylon

- ABS

- Polycarbonate (PC)

A high-level CNC machining factory understands cutting parameters, tool wear, and thermal behavior for each material, ensuring consistent dimensional accuracy.

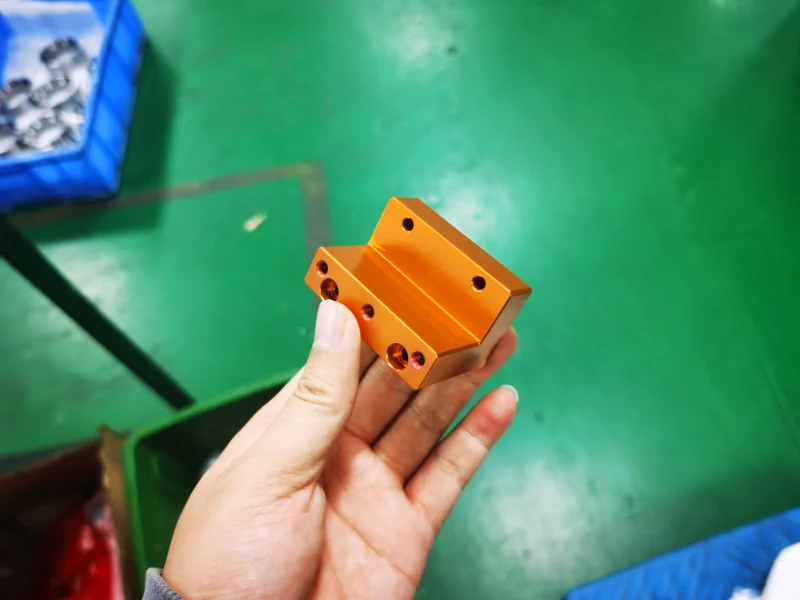

Surface Finishing Options from CNC Machining Suppliers

Beyond raw machining, surface treatment is essential for function, corrosion resistance, and appearance. A competitive cnc custom machining manufacturer should offer integrated or outsourced surface finishing solutions.

Common Surface Treatments

- Anodizing (Type II and Type III hard anodizing)

- Powder coating

- Black oxide

- Electropolishing

- Passivation

- Zinc, nickel, or chrome plating

- Bead blasting and polishing

By offering multiple surface finishes, a CNC machining supplier reduces lead time and ensures quality consistency across production batches.

CNC Custom Machining Cost: Typical Price Ranges

Cost transparency is a major concern when working with a cnc custom machining manufacturer. Pricing depends on material, tolerance, part complexity, volume, and finishing requirements.

Typical CNC Machining Cost Ranges (USD)

- Simple aluminum parts: $10 – $50 per piece

- Complex 5-axis parts: $50 – $300+ per piece

- Prototype machining: $80 – $500 per part

- High-volume production: $3 – $20 per piece (depending on volume)

An experienced CNC machining factory will provide detailed quotations covering machining time, material cost, tooling, surface treatment, and quality inspection.

How to Evaluate a CNC Custom Machining Supplier

Choosing the right cnc custom machining manufacturer requires more than comparing prices. Long-term reliability depends on technical strength and operational stability.

Key Evaluation Criteria

- Machining capability and equipment

Look for multi-axis CNC machines and modern inspection tools such as CMMs. - Material and finishing range

A diversified CNC machining supplier reduces the need for secondary vendors. - Quality management system

ISO 9001 or industry-specific certifications demonstrate process control. - Engineering communication

A professional manufacturer provides DFM feedback and technical guidance. - Lead time and scalability

The right CNC machining factory can scale from prototypes to mass production. - Export and logistics experience

Especially important for international sourcing.

Common Mistakes When Selecting a CNC Machining Manufacturer

Many buyers focus solely on low prices and overlook long-term risks. When selecting a cnc custom machining manufacturer, avoid these common mistakes:

- Choosing suppliers without proven tolerance control

- Ignoring material traceability

- Overlooking surface finish quality

- Working with factories lacking engineering support

- Selecting suppliers with poor communication response times

A reliable CNC machining supplier prioritizes consistency and partnership over short-term pricing.

Why Custom CNC Machining Is Ideal for Complex Parts

Custom CNC machining enables design flexibility that standard manufacturing methods cannot offer. A qualified cnc custom machining manufacturer can produce:

- Complex internal features

- Tight tolerance assemblies

- Low-volume, high-mix components

- Rapid design iterations

This makes CNC custom machining ideal for medical, aerospace, and high-performance industrial applications.

Partnering with a Trusted CNC Custom Machining Manufacturer

At Weldo Machining, we operate as a full-service cnc custom machining manufacturer, providing precision CNC machining, advanced materials processing, and reliable surface finishing solutions. As an experienced CNC machining factory and supplier, we support customers from prototype development to high-volume production with consistent quality and competitive pricing.

If you are searching for a dependable CNC machining supplier that combines engineering expertise, cost efficiency, and responsive service, contact Weldo Machining today for detailed technical consultation and a fast quotation tailored to your project requirements.