Understanding the true cnc engine block machining cost is essential for automotive builders, race teams, engine tuners, and manufacturers who rely on precision-engineered blocks for high-power and high-reliability performance. From aluminum racing blocks to cast iron heavy-duty engines, machining cost varies based on material hardness, design complexity, bore size, honed surfaces, and performance requirements. This guide breaks down materials, performance impact, machining processes, and the real cost factors that influence both prototype and full-production engine block machining.

What Influences CNC Engine Block Machining Cost?

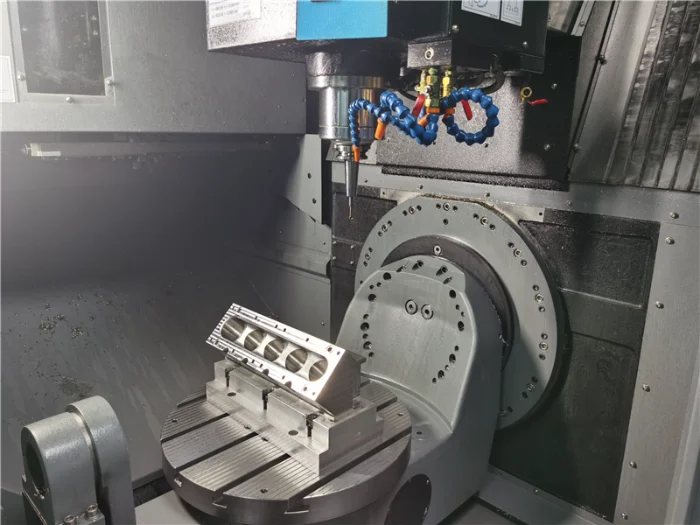

A well-machined engine block requires precision metalworking, multiple CNC operations, and strict tolerance control. Because of this, the cnc engine block machining cost depends on several key technical factors.

1. Material Type and Hardness

Material hardness is one of the strongest indicators of both machining time and the final cnc engine block machining price.

Aluminum Engine Blocks (6061, 7075, A356-T6)

- Lightweight

- Easier to machine

- High thermal conductivity

Cost impact:

Lower machining cost due to easier tool passes and reduced cycle time.

Cast Iron Engine Blocks

- High rigidity

- Excellent wear resistance

- Strong under high horsepower and torque

Cost impact:

Medium to high cost due to slow cutting speeds and greater tool wear.

Compacted Graphite Iron (CGI)

- 75% stronger than cast iron

- Excellent fatigue resistance

Cost impact:

High machining cost—CGI requires special tooling and slower feeds.

Billet Steel Blocks

- Maximum rigidity

- Used in extreme racing builds

Cost impact:

Highest machining cost because steel requires precision tools, long machining cycles, and expensive finishing.

How Performance Requirements Affect CNC Engine Block Machining Cost

Engine blocks designed for high horsepower (HP) and torque require additional machining precision and reinforcement steps.

1. Horsepower Limits (HP)

Higher power requires stronger structural accuracy:

| HP Range | Required Machining Level |

|---|---|

| 300–600 HP | Standard machining |

| 600–1,200 HP | High-precision surfacing + improved oil passages |

| 1,200–2,000 HP | Reinforced block + tight-tolerance machining |

| 2,000–3,000+ HP | Billet block + race-grade CNC machining |

More boost + more heat = higher cnc engine block machining cost.

2. Torque Resistance

Torque places extreme stress on:

- Main caps

- Cylinder walls

- Crankshaft tunnel

- Deck surface

Engines exceeding 800–1,500 Nm require:

- Line honing

- Deck reinforcement

- Stronger materials

These additional machining steps directly affect the cnc engine block machining price.

3. High RPM Stability

High-RPM race engines require:

- Dead-straight crank tunnels

- Perfectly matched cylinder bores

- Balanced main bearing alignment

Premium accuracy demands slow feed rates and more inspection time, increasing cost.

Machining Processes That Influence Engine Block Machining Cost

Engine block machining includes multiple CNC operations, each contributing to the final cnc engine block machining cost.

CNC Boring

Purpose

- Enlarges and corrects cylinder bore geometry

- Ensures consistent cylinder diameter

Cost Impact

Moderate, depending on number of cylinders and bore increase.

Cylinder Honing

Purpose

- Creates crosshatch pattern for oil retention

- Ensures piston ring seating

- Enhances compression and performance

Cost Impact

Higher for race-grade plateau honing.

Deck Surfacing

Purpose

- Creates perfectly flat deck surface

- Improves head gasket sealing

- Essential for high boost engines

Cost Impact

Moderate to high, depending on required flatness tolerance.

Line Honing / Line Boring

Purpose

- Realigns crankshaft & camshaft tunnels

- Reduces bearing wear

- Improves high-RPM stability

Cost Impact

One of the more expensive processes due to precision tools.

Oil Passage Machining

Purpose

- Improves lubrication

- Reduces engine temperature

- Enhances long-term durability

Cost Impact

Relatively low unless complex passage redesign is needed.

Common Surface Treatments for Engine Block Machining

Proper finishing extends engine life and supports high power levels. These processes also contribute to the final cnc engine block machining cost.

Thermal Barrier Coating

Benefits

- Reduces heat transfer

- Protects pistons and walls

Anti-Corrosion Coating

Benefits

- Prevents rust

- Improves durability in high-humidity operations

Oil-Shedding Coating

Benefits

- Reduces friction

- Improves oil distribution at high RPM

Cylinder Wall Coating (Nikasil / Iron Plating)

Benefits

- Enhances wear resistance

- Supports extreme horsepower

Cost Impact

Medium to high depending on thickness and treatment method.

Estimated CNC Engine Block Machining Cost

Actual cnc engine block machining price varies by specifications, but general estimates include:

| Engine Type | Typical Machining Cost |

|---|---|

| 4-cylinder aluminum block | $300–$800 |

| 6-cylinder aluminum block | $500–$1,100 |

| V8 cast iron block | $700–$1,500 |

| Billet racing block | $2,000–$6,000+ |

Precision machining, high horsepower demands, or exotic materials can increase cost significantly.

How to Reduce CNC Engine Block Machining Cost

Choose a material that matches performance needs

Avoid over-specifying billet steel when aluminum suffices.

Optimize bore/hone requirements

Standard tolerances reduce machining time.

Simplify oil passage redesigns

Complex lubrication channels raise costs.

Use standard coatings when applicable

Performance coatings increase cost but may be unnecessary in moderate HP builds.

Increase order quantity

Batch machining reduces setup cost per block.

Request CNC Engine Block Machining Cost — Contact Weldo Machining

For precise, durable, and performance-focused engine block machining, choosing a professional partner is essential. As an experienced provider of cnc engine block machining cost solutions, Weldo Machining supports aluminum, cast iron, CGI, and billet materials with high-tolerance boring, honing, decking, and finishing capabilities. Whether you need prototype development or high-HP racing engine blocks, our team delivers consistent accuracy and competitive pricing.

Contact us today for accurate quotations, performance guidance, and tailored CNC engine block machining solutions.

FAQ of CNC Engine Block Machining Cost

What affects CNC engine block machining cost the most?

Material hardness, bore size, tolerances, coatings, and performance requirements contribute most to final cost.

How does machining affect engine horsepower capability?

Precision boring, honing, and deck surfacing improve ring sealing, boost tolerance, and torque stability.

What surface treatments improve engine block life?

Honing, thermal coatings, oil-shedding coatings, and anti-corrosion processes enhance durability and power handling.