Choosing a reliable cnc engine block machining manufacturer is essential for builders, automotive engineers, and performance shops who demand precision, durability, and maximum horsepower capability. Engine blocks require tight tolerances, advanced machining sequences, and material expertise to support combustion pressure, extreme heat, and high RPM operation. This guide explains materials, machining techniques, performance impact, surface treatment processes, and how to select the right partner for professional engine block manufacturing.

Why a Professional CNC Engine Block Machining Manufacturer Matters

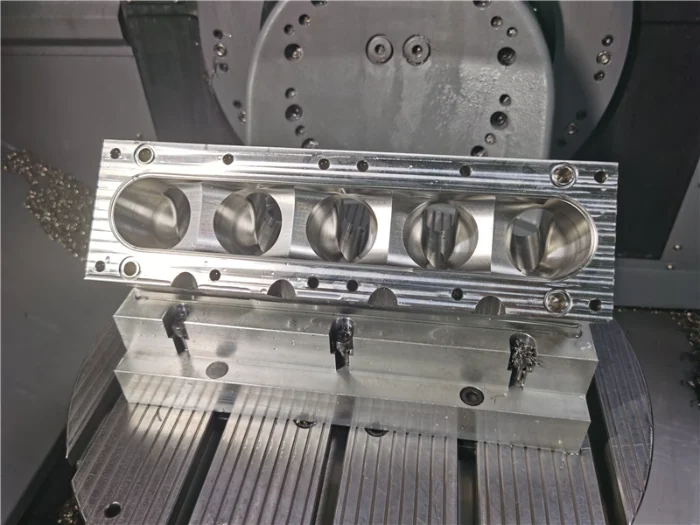

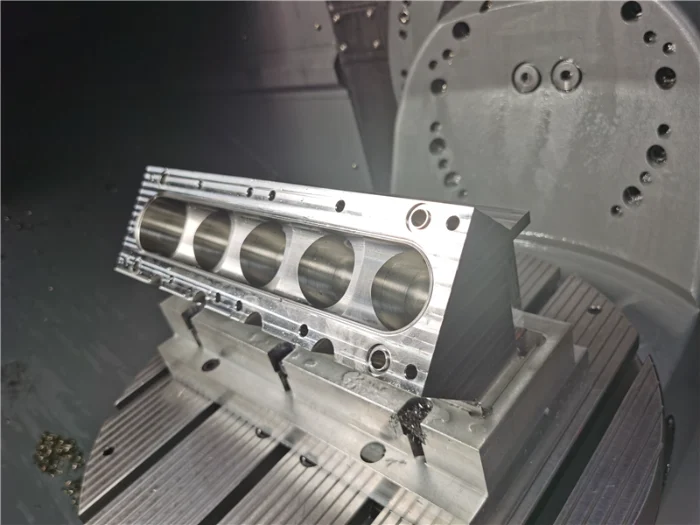

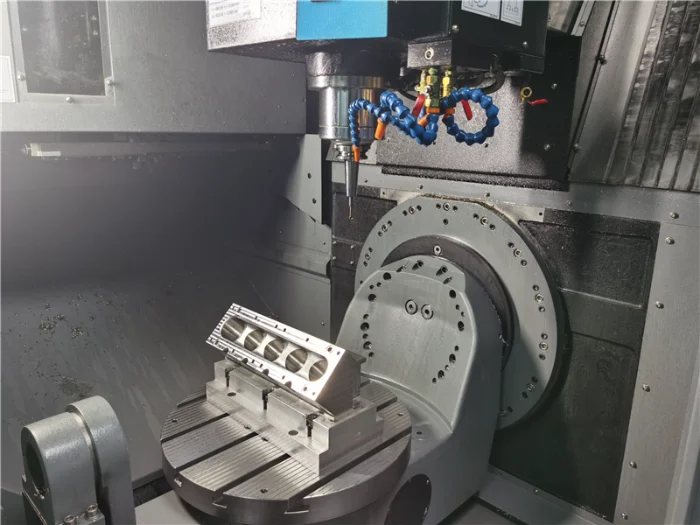

A high-quality cnc engine block machining manufacturer ensures that every bore, deck surface, oil passage, and crank tunnel meets exact tolerances required for stable combustion, lubrication, and long engine life. Advanced CNC machining is critical because even tiny deviations can cause power loss, hot spots, cylinder imbalance, and premature engine wear.

What a Good Manufacturer Provides

- High-accuracy CNC boring, honing, and surfacing

- Consistent tolerances across all cylinders

- Proper alignment of crankshaft and camshaft tunnels

- Material expertise for different power applications

- Performance-focused machining setups

- Experience producing high-horsepower engine blocks

A premium cnc engine block machining supplier ensures peak engine efficiency and reliability.

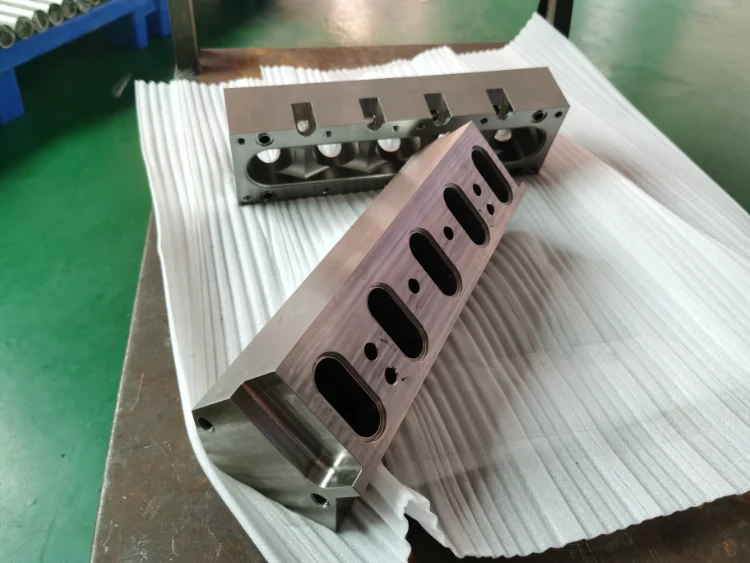

Material Options for CNC Engine Block Machining

Engine block material selection has a direct impact on weight, cooling efficiency, block rigidity, and horsepower limits. A professional cnc engine block machining factory typically supports the following materials:

1.Aluminum Engine Blocks (6061, 7075, A356-T6)

Features

- Lightweight

- Excellent thermal conductivity

- Easier machining

Performance Impact

- Ideal for racing, drifting, and high-speed applications

- Supports 600–1,500+ HP depending on reinforcement and sleeve type

- Perfect for turbo and supercharged setups with proper strengthening

Aluminum blocks are often CNC-machined for aftermarket performance builds.

2.Cast Iron Engine Blocks (Grey Iron, Ductile Iron)

Features

- Higher rigidity

- Superior wear resistance

- Better stability under high load

Performance Impact

- Stock and performance builds up to 1,500–2,500 HP

- Excellent for high-boost and high-RPM engines

- Great structural strength for endurance engines

Cast iron blocks offer maximum durability for heavy-duty builds.

3.Compacted Graphite Iron (CGI)

Features

- Stronger than cast iron

- Better fatigue resistance

- Lighter than traditional iron

Performance Impact

- Used in modern diesel and high-pressure turbo engines

- Supports extreme torque applications

- Capable of handling 2,000+ HP with proper machining

CGI is ideal for commercial, diesel, and industrial performance blocks.

4.Steel and Billet Engine Blocks

Features

- Ultimate rigidity and strength

- Customizable geometry

- Often used in top-level motorsports

Performance Impact

- Supports 3,000+ HP drag racing builds

- High boost environments

- Extreme durability and heat resistance

Billet blocks are the pinnacle of performance engineering.

How Engine Block Machining Affects Horsepower and Torque

Precise machining directly impacts combustion strength, piston sealing, and crankshaft stability. The capabilities of a cnc engine block machining manufacturer determine how much horsepower and torque a block can safely handle.

1. Cylinder Bore Accuracy

- Proper bore geometry ensures full piston contact

- Reduces blow-by and increases compression

- Supports higher horsepower and better efficiency

Tolerance

- Typically ±0.01–0.02 mm for performance engines

2. Deck Surface Flatness

- Critical for head gasket sealing

- Prevents combustion leaks

- Needed for high-compression and boosted engines

Impact on Performance

Better sealing supports higher boost pressure and torque output.

3. Crankshaft Tunnel Alignment (Line Honing)

- Ensures smooth crank rotation

- Reduces bearing wear

- Increases high-RPM stability

This machining step affects how well the engine handles extreme torque.

4. Oil Passage Optimization

- Improves oil flow

- Reduces heat

- Enhances lubrication during high RPM

Proper oiling increases horsepower reliability in racing engines.

Common Surface Treatment Processes for Engine Block Machining

Surface treatments improve sealing, oil retention, heat transfer, and durability. They also influence engine longevity and power handling capability.

Cylinder Honing

Purpose

- Creates crosshatch surface

- Improves oil retention

- Ensures piston ring seating

Effect on Performance

Enhances compression and torque output.

CNC Boring

Purpose

- Enlarges cylinders precisely

- Corrects shape distortion

- Prepares for oversized pistons

Ideal for rebuilds and performance upgrades.

Decking (Surface Milling)

Purpose

- Flattens deck surface

- Ensures proper sealing with cylinder head

Performance Benefit

Allows higher boost pressure and higher HP limits.

Line Honing / Line Boring

Purpose

- Aligns crankshaft and camshaft tunnels

- Reduces friction and bearing wear

Performance Benefit

Improves high-RPM stability under heavy torque.

Protective Coatings

Options

- Anti-corrosion coating

- Thermal barrier coating

- Oil-shedding coatings

Benefits

- Reduces heat

- Prevents rust

- Improves internal surface efficiency

Advanced coatings are common in blocks machined by a top-tier cnc engine block machining supplier.

Applications of CNC Engine Block Machining

Automotive Performance & Motorsports

- Drag racing engines

- Drift motors

- High-boost turbo builds

- Supercharged street engines

Diesel Performance

- Heavy-duty truck engines

- Industrial powerplants

- High-torque diesel racing blocks

OEM & Aftermarket Engine Manufacturing

- High-volume engine platform machining

- Custom engine prototypes

- Model-specific performance upgrades

Marine Engines

- High-output performance boats

- Salt-resistant machining with coatings

How to Choose the Right CNC Engine Block Machining Manufacturer

Key Qualities

- Experience with high-horsepower builds

- Capability in precision boring and honing

- Multi-axis machining capabilities

- Full inspection and QC processes

- Support for billet, aluminum, iron, and CGI materials

- Long-term reliability and repeatability

A premium cnc engine block machining factory ensures performance engines deliver maximum durability.

Request CNC Engine Block Machining Quotes — Contact Weldo Machining

Finding the right machining partner is crucial for maximizing engine durability and horsepower output. As a professional cnc engine block machining manufacturer, Weldo Machining offers multi-material support, high-tolerance machining, advanced honing and boring capabilities, and performance-focused manufacturing. Whether you need prototypes, small-batch machining, or full-scale engine block production, our team delivers high precision with competitive pricing.

Contact us today for detailed quotations and technical guidance for your CNC engine block machining project.

FAQ of CNC Engine Block Machining Manufacturer

What does a CNC engine block machining manufacturer do?

They perform precision boring, honing, surfacing, and alignment machining to produce high-performance, durable engine blocks.

Which materials are best for CNC-machined engine blocks?

Common options include aluminum, cast iron, CGI, and billet steel depending on horsepower and torque requirements.

What surface treatments are commonly used on engine blocks?

Cylinder honing, decking, line honing, and protective coatings improve sealing, oil flow, and heat resistance.