A cnc hastelloy part is specifically designed for extreme corrosion, pressure, and temperature environments where conventional stainless steels or standard nickel alloys are not sufficient. Hastelloy is a family of nickel-based superalloys, and each grade offers unique physical properties and application advantages. This article explains how different Hastelloy grades perform, where each cnc hastelloy part is typically used, and why precision CNC machining is essential for reliable Hastelloy components.

Why CNC Hastelloy Part Selection Depends on Alloy Properties

Choosing the right cnc hastelloy component starts with understanding material behavior. Hastelloy alloys differ in chemical composition, which directly affects:

- Tensile strength

- Yield strength

- Temperature resistance

- Corrosion resistance

- Machinability

Matching alloy properties with real application conditions is critical for performance and cost control.

Overview of Common Hastelloy Grades for CNC Machining

Most cnc hastelloy part projects focus on a limited number of proven Hastelloy grades. Below are the most commonly machined alloys in industrial applications.

Hastelloy C-276: The Most Widely Used CNC Hastelloy Part

Physical Properties

- Density: ~8.9 g/cm³

- Tensile strength: ~790 MPa

- Yield strength: ~355 MPa

- Maximum service temperature: ~1040°C

Hastelloy C-276 offers outstanding resistance to both oxidizing and reducing environments.

Typical Applications

- Chemical processing equipment

- Oil and gas components

- Flue gas desulfurization systems

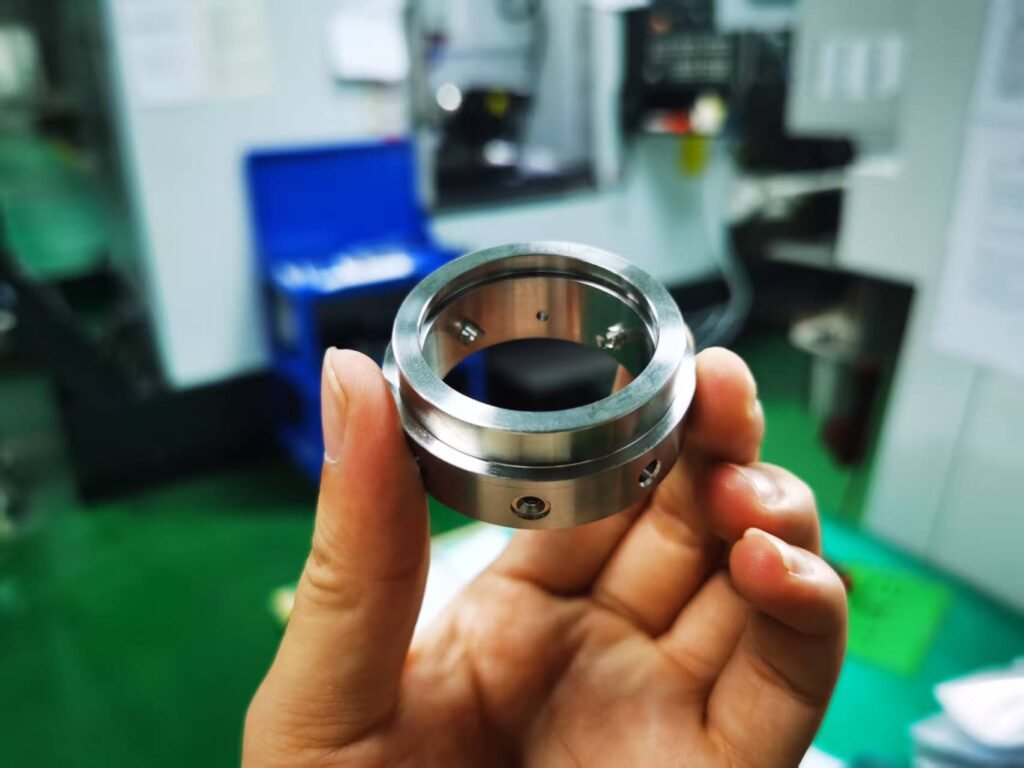

Common CNC Hastelloy Part Components

- Valve bodies

- Pump housings

- Pipe fittings

- Heat exchanger plates

C-276 is often the first choice for general-purpose cnc hastelloy part manufacturing.

Hastelloy C-22: Superior Resistance to Pitting and Crevice Corrosion

Physical Properties

- Density: ~8.7 g/cm³

- Tensile strength: ~690 MPa

- Yield strength: ~310 MPa

- Excellent resistance to localized corrosion

Compared to C-276, Hastelloy C-22 provides enhanced protection in chloride-rich environments.

Typical Applications

- Pharmaceutical processing

- Marine and offshore equipment

- High-purity chemical systems

Common CNC Hastelloy Part Components

- Precision flanges

- Sealing rings

- Reactor internals

- Corrosion-critical fasteners

A cnc hastelloy part made from C-22 is ideal where failure from pitting corrosion must be avoided.

Hastelloy X: High-Temperature Strength Focused CNC Hastelloy Part

Physical Properties

- Density: ~8.2 g/cm³

- Tensile strength: ~760 MPa

- Yield strength: ~345 MPa

- Excellent oxidation resistance at high temperatures

Hastelloy X emphasizes thermal stability rather than extreme chemical resistance.

Typical Applications

- Aerospace structures

- Gas turbine components

- High-temperature furnace parts

Common CNC Hastelloy Part Components

- Combustion hardware

- Structural brackets

- Heat shields

- Engine casings

For applications requiring temperature stability, Hastelloy X cnc hastelloy parts outperform many alternatives.

Hastelloy B-3: Optimized for Strong Acid Environments

Physical Properties

- Density: ~9.2 g/cm³

- Tensile strength: ~760 MPa

- Yield strength: ~365 MPa

- Exceptional resistance to hydrochloric acid

Hastelloy B-3 is engineered specifically for reducing acid environments.

Typical Applications

- Acid reactors

- Chemical storage systems

- Pickling equipment

Common CNC Hastelloy Part Components

- Acid transfer valves

- Reaction vessels

- Nozzles and connectors

A cnc hastelloy part made from B-3 is often irreplaceable in aggressive acid service.

CNC Hastelloy Part Machinability Comparison by Alloy

Different Hastelloy grades require different machining strategies.

- C-276: Most balanced machinability

- C-22: Slightly tougher, requires conservative parameters

- X: Better thermal behavior, still tool-intensive

- B-3: High cutting resistance, careful process control required

Weldo Machining optimizes tool paths and cutting parameters based on the specific cnc hastelloy base material selected.

CNC Hastelloy Part Machining Challenges and Solutions

Machining a cnc hastelloy component is significantly more complex than machining stainless steel or common nickel alloys. Hastelloy is designed for extreme corrosion and temperature resistance, which directly leads to higher machining difficulty. Understanding the key challenges and applying proper solutions is essential for reliable cnc machining hastelloy part production.

Challenge 1: Severe Work Hardening

One of the biggest challenges in producing a cnc hastelloy componentis rapid work hardening. If cutting conditions are not optimized, the material hardens quickly, increasing tool wear and reducing surface quality.

Solutions:

- Maintain continuous cutting without tool dwell

- Use sharp carbide tools designed for nickel alloys

- Apply proper feed rates to avoid tool rubbing

Effective control of work hardening improves both surface finish and tool life in cnc machining hastelloy part operations.

Challenge 2: High Heat Concentration During Machining

Hastelloy has poor thermal conductivity, causing heat to concentrate at the cutting edge when machining a cnc hastelloy component. Excessive heat leads to rapid tool failure and unstable machining.

Solutions:

- Reduce cutting speed while maintaining stable feed

- Use high-pressure or flood coolant

- Select heat-resistant tool coatings

Thermal control is a critical factor in achieving consistent quality for cnc hastelloy base components.

Challenge 3: High Cutting Force and Tool Wear

The high strength and toughness of Hastelloy result in greater cutting resistance when producing a cnc hastelloy component, directly impacting machining cost and efficiency.

Solutions:

- Use rigid CNC machines and stable fixturing

- Optimize tool paths to reduce cutting load

- Standardize proven machining parameters

Managing cutting force effectively reduces tool wear and improves cost control for cnc machining hastelloy part production.

Why Experienced CNC Suppliers Matter for Hastelloy Parts

Due to these challenges, a cnc hastelloy part should be manufactured by suppliers with proven nickel-alloy machining experience. Proper process planning, tooling selection, and machining control significantly reduce risk, lead time, and overall cost.

Weldo Machining applies optimized CNC strategies to deliver high-quality cnc hastelloy parts for corrosion-critical and high-performance applications.

Surface Finish Requirements for CNC Hastelloy Parts by Application

Surface condition strongly affects the service life of a cnc hastelloy part.

Common finishes include:

- Precision as-machined

- Sand blasting or bead blasting

- Electropolishing for clean systems

- Passivation for corrosion enhancement

Finish selection depends on media exposure, cleanliness standards, and sealing performance.

Cost Considerations for Different CNC Hastelloy Parts

The cost of a cnc hastelloy part varies significantly by alloy type.

Key cost drivers:

- Raw material price differences between grades

- Tool wear rate

- Machining time

- Inspection requirements

For example, C-22 and B-3 typically cost more to machine than C-276 due to increased tool wear.

Typical Industries Using CNC Hastelloy Component

A cnc hastelloy part is commonly specified in:

- Chemical and petrochemical processing

- Oil and gas equipment

- Aerospace and energy systems

- Environmental and pollution control

In these industries, component failure can result in severe safety and financial consequences.

Why Weldo Machining for CNC Hastelloy Parts

Weldo Machining has extensive experience producing cnc hastelloy parts across multiple grades and applications. Our engineering team supports customers with:

- Alloy selection guidance

- Optimized CNC machining strategies

- Tight tolerance control

- Reliable delivery for prototypes and production

Conclusion: Matching Hastelloy Properties to CNC Hastelloy Part Applications

Selecting the correct hastelloy part requires understanding both alloy physical properties and real-world application conditions. Different Hastelloy grades serve different performance needs, from acid resistance to high-temperature stability. With the right machining partner, cnc hastelloy parts deliver unmatched durability and reliability. Contact Weldo Machining to discuss your Hastelloy project and receive a professional quote.