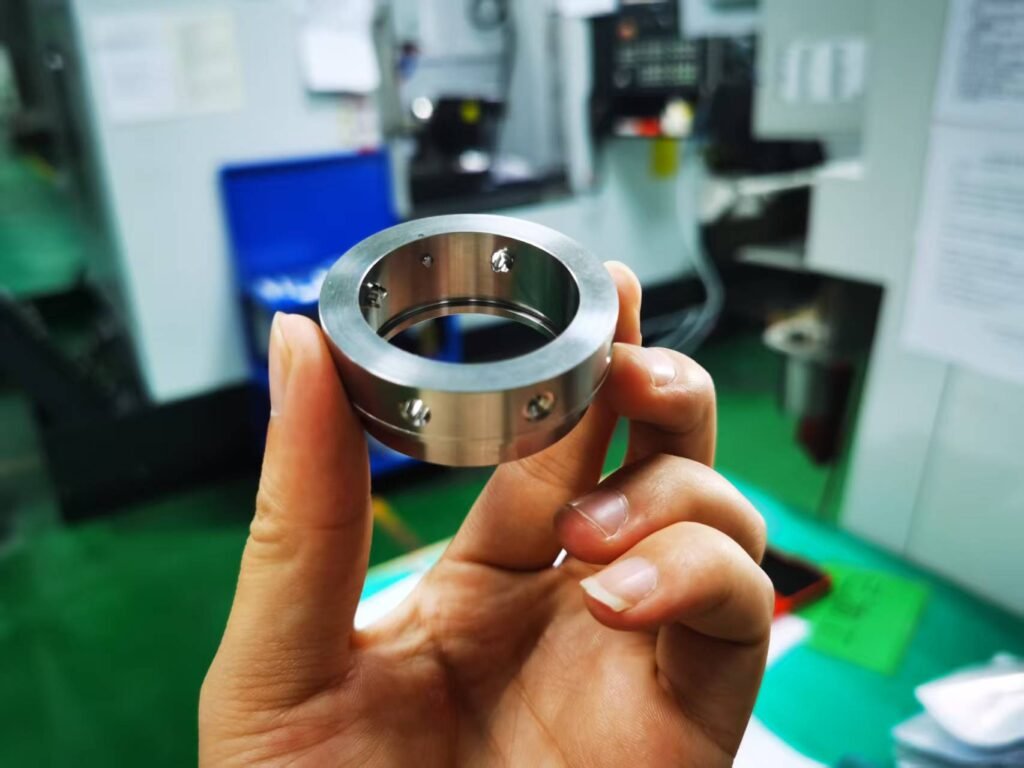

A cnc hastelloy prototype is often the first critical step in validating part performance for extreme corrosion, pressure, or temperature environments. Before full-scale production, engineers rely on cnc hastelloy prototypes to test material behavior, machining feasibility, and functional reliability. This article explains why Hastelloy is widely used for prototyping, how cnc hastelloy prototype machining works, cost considerations, and how to choose the right supplier for high-risk applications.

Why CNC Hastelloy Prototype Is Essential Before Production

Developing a cnc hastelloy sample allows manufacturers to reduce technical and financial risk before committing to expensive production tooling. Hastelloy is a premium nickel-based alloy, and prototyping helps confirm that the design, material grade, and machining process meet real-world requirements.

Key objectives of cnc hastelloy prototype development include:

- Verifying corrosion and temperature performance

- Testing assembly fit and sealing surfaces

- Evaluating machinability and tolerance control

- Identifying cost drivers early in the project

A properly executed cnc hastelloy prototype significantly improves downstream production success.

Hastelloy Material Characteristics for Prototype Machining

A cnc hastelloy part is typically machined from grades such as C-276, C-22, X, or B-3, each offering different performance characteristics.

Key material traits affecting prototyping:

- High strength and toughness

- Excellent corrosion resistance

- Poor thermal conductivity

- Tendency toward work hardening

These properties make cnc machining hastelloy sample parts more complex than standard stainless steel prototypes.

CNC Machining Hastelloy Sample: From Design to Prototype

Producing a cnc machining hastelloy sample requires careful coordination between design and manufacturing.

Design Considerations

- Avoid unnecessary thin walls

- Maintain realistic tolerances

- Allow proper tool access

Machining Considerations

- Optimized cutting parameters

- Specialized tooling for nickel alloys

- Stable fixturing and rigid machines

Early design-for-manufacturing (DFM) input improves cnc hastelloy prototype quality and reduces rework.

CNC Hastelloy Prototype vs Production Parts

A hastelloy prototype is not simply a scaled-down production part. Its purpose is validation, not cost optimization.

Key differences include:

- Lower volume, higher unit cost

- Greater flexibility in design changes

- More inspection and testing

- Shorter lead times

Prototype machining focuses on accuracy and performance rather than cycle-time efficiency.

Machining Challenges in CNC Hastelloy Prototype Development

Machining a cnc hastelloy prototype presents specific technical challenges that must be addressed early.

Work Hardening

Hastelloy hardens rapidly during cutting if tool engagement is unstable.

Heat Buildup

Low thermal conductivity causes localized heat concentration at the cutting edge.

Tool Wear

Nickel alloys accelerate tool degradation, increasing prototype cost.

Experienced suppliers mitigate these risks through optimized tool paths, proper feed rates, and advanced coolant strategies.

Surface Finish Options for CNC Hastelloy Prototype

Surface condition is often critical during prototype evaluation. A cnc prototype may require different finishes depending on its testing purpose.

Common finishes include:

- Precision as-machined finish

- Sand blasting or bead blasting

- Electropolishing for clean systems

- Passivation for enhanced corrosion resistance

Surface finish selection directly affects prototype testing results.

CNC Hastelloy Prototype Cost Factors

The cost of a cnc hastelloy sample is influenced by several variables.

Major cost drivers:

- Hastelloy raw material price

- Machining time and tool wear

- Complexity of geometry

- Tolerance and inspection requirements

- Surface finishing needs

While prototype cost is higher than common alloys, it prevents costly design errors during production.

Typical Applications of CNC Hastelloy Prototypes

A cnc hastelloy prototype is commonly used in industries where failure is not acceptable.

Typical application areas include:

- Chemical processing equipment

- Oil and gas components

- Aerospace structures

- Pollution control systems

- High-temperature energy equipment

Prototype testing ensures long-term reliability under harsh operating conditions.

Quality Control for CNC Hastelloy Prototype Machining

Quality verification is essential for every cnc hastelloy part.

Common inspection steps:

- Material certification verification

- Dimensional inspection

- Surface roughness measurement

- Functional or pressure testing (if required)

High-quality cnc machining hastelloy sample parts provide reliable data for design validation.

Why Choose Weldo Machining for CNC Hastelloy Prototype Projects

Weldo Machining specializes in high-precision cnc hastelloy sample manufacturing for demanding industries. Our team supports customers from early concept through validated prototype delivery.

We offer:

- Proven experience in nickel alloy machining

- Advanced CNC equipment for complex geometries

- DFM support to optimize prototype designs

- Fast turnaround with controlled quality

Whether you need a single cnc machining hastelloy sample or a small prototype batch, we provide reliable technical support.

Conclusion: CNC Hastelloy Prototype as a Strategic Engineering Step

A cnc hastelloy prototype plays a critical role in validating design, material performance, and manufacturability before full production. By investing in precision prototype machining, manufacturers reduce risk and improve long-term project success. If you are planning a Hastelloy prototype project, contact Weldo Machining for expert guidance, fast lead times, and competitive pricing.