Understanding cnc machined components cost is critical for engineers and procurement teams sourcing custom parts. CNC machining provides high precision and flexibility, but cost varies significantly depending on material selection, mechanical performance requirements, surface finishing, and production volume.

This guide explains how cnc machined components cost is calculated, compares metal and engineering plastic materials with mechanical properties, and provides realistic USD price ranges before and after surface treatment.

Why CNC Machined Components Cost Varies

There is no fixed price for CNC machined parts. Cnc machined components cost is driven by multiple interacting factors:

- Material type and machinability

- Mechanical performance requirements

- Part geometry and tolerance

- Surface finishing processes

- Order quantity

Among these, material choice and surface treatment together account for the largest cost variation.

CNC Machined Components Cost by Material and Mechanical Properties

Material selection should be based on required mechanical performance, not over-specification. Choosing materials with unnecessary strength or temperature resistance directly increases cnc machined components cost.

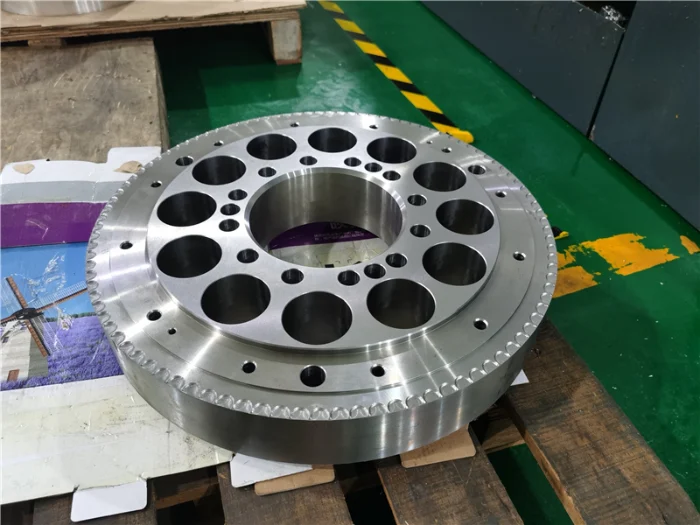

Metal CNC Machined Components: Properties and Cost

Aluminum Alloys (6061 / 7075)

Mechanical properties:

- Density: ~2.7 g/cm³

- Tensile strength:

- 6061-T6: ~310 MPa

- 7075-T6: ~570 MPa

- Excellent strength-to-weight ratio

Base CNC cost (no finish):

- USD 30–120 / part (prototype)

- USD 10–60 / part (volume)

After surface treatment:

- Anodized aluminum: USD 45–180 / part

- Hard anodized aluminum: USD 60–250 / part

Aluminum offers the best balance between mechanical performance and low cnc machined components cost.

Carbon Steel & Alloy Steel

Mechanical properties:

- High tensile and yield strength

- Good toughness and wear resistance

Base CNC cost:

- USD 50–180 / part

After surface treatment:

- Black oxide / coating: USD 70–240 / part

- Heat-treated steel: USD 90–300 / part

Steel is suitable for load-bearing components where strength is critical.

Stainless Steel (304 / 316 / 17-4PH)

Mechanical properties:

- Tensile strength: ~520–1100 MPa

- Excellent corrosion resistance

Base CNC cost:

- USD 80–300 / part

After surface treatment:

- Passivated stainless steel: USD 100–360 / part

- Polished / electropolished: USD 130–450 / part

Stainless steel increases cnc machined components cost but is essential for corrosive environments.

Titanium Alloys

Mechanical properties:

- High strength-to-weight ratio

- Excellent fatigue resistance

Base CNC cost:

- USD 150–500+ / part

After surface treatment:

- Anodized / treated titanium: USD 200–650+ / part

Titanium is justified mainly for aerospace and medical applications.

Nickel-Based Alloys (Inconel / Hastelloy)

Mechanical properties:

- Outstanding high-temperature strength

- Exceptional corrosion resistance

Base CNC cost:

- USD 250–1,000+ / part

After surface treatment:

- Heat-treated / coated: USD 320–1,300+ / part

These alloys represent the highest cnc machined components cost category.

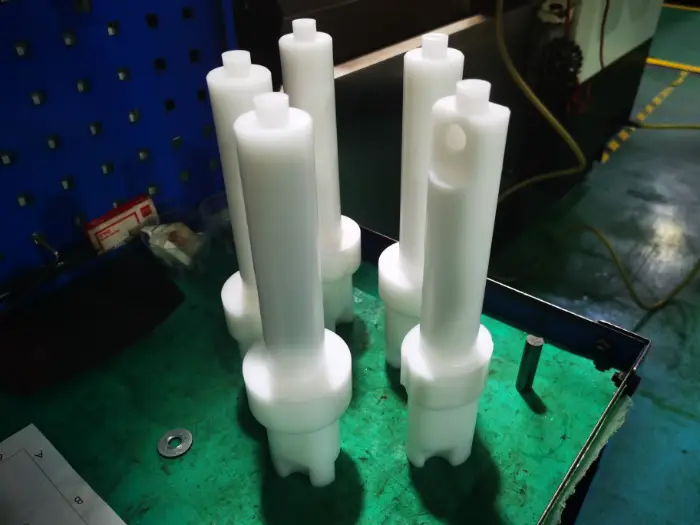

Engineering Plastic CNC Machined Components: Properties and Cost

Engineering plastics are core cost-optimization materials, not substitutes. For many applications, they meet functional requirements at a significantly lower cnc machined components cost.

ABS

Mechanical properties:

- Moderate tensile strength

- Good impact resistance

Base CNC cost:

- USD 20–80 / part

After surface treatment:

- Polished / coated ABS: USD 35–120 / part

Nylon (PA6 / PA66)

Mechanical properties:

- Good strength and wear resistance

- Moderate impact resistance

Base CNC cost:

- USD 25–90 / part

After surface treatment:

- Polished nylon parts: USD 40–140 / part

POM (Delrin / Acetal)

Mechanical properties:

- High stiffness

- Excellent dimensional stability

- Low friction

Base CNC cost:

- USD 30–120 / part

After surface treatment:

- Polished / precision-finished: USD 45–180 / part

PTFE (Teflon)

Mechanical properties:

- Extremely low friction

- Excellent chemical resistance

- Low mechanical strength

Base CNC cost:

- USD 60–200 / part

After surface treatment:

- Precision-finished PTFE: USD 80–260 / part

PEEK

Mechanical properties:

- Tensile strength: ~90–100 MPa

- Excellent thermal and chemical resistance

Base CNC cost:

- USD 120–400 / part

After surface treatment:

- Precision-machined PEEK: USD 150–520 / part

In many cases, PEEK reduces total cnc machined components cost compared to stainless steel or titanium.

Surface Finishing Options and Cost Impact

Surface finishing affects performance, appearance, and cnc machined components cost. Selecting only functionally necessary finishes is critical for cost control.

Common Surface Finishes for Metals

- Anodizing (aluminum)

- Plating

- Passivation

- Polishing / electropolishing

- Heat treatment

Common Surface Finishes for Engineering Plastics

- As-machined finish (lowest cost)

- Polishing

- Sandblasting

- Functional coatings

Plastic parts generally require fewer finishing steps, contributing to lower total cnc machined components cost.

How Surface Finishing Changes CNC Machined Components Cost

- Basic finishes add 15–40% to base cost

- Decorative or precision finishes add 30–70%

- Tight roughness requirements increase machining time

Matching finish to real functional needs avoids unnecessary cost escalation.

CNC Machined Components Cost by Production Volume

- 1–5 pcs: highest unit cost

- 10–100 pcs: 20–40% cost reduction

- 100+ pcs: lowest unit cost

Repeat orders further reduce cnc machined components cost through optimized processes.

Conclusion: Managing CNC Machined Components Cost Effectively

Cnc machined components cost is driven by material mechanical properties, machining complexity, and surface finishing choices. By evaluating metal and engineering plastic materials, understanding their mechanical performance, and selecting appropriate surface treatments, manufacturers can achieve the best balance between performance, quality, and cost.

For accurate pricing and expert guidance, contact Weldo Machining to receive a tailored CNC machining quotation.