CNC machining 16MnCr5 prototype manufacturing is widely used for developing high-precision transmission components that require excellent wear resistance, dimensional stability, and long service life. As a low-alloy steel, 16MnCr5 is especially suitable for synchronizer rings and other functional parts that operate under repeated friction and load cycles.

This article introduces a cnc machining 16MnCr5 prototype through a simplified 5 Axis CNC Machining Synchronizer Ring case, highlighting material selection, machining requirements, and process advantages.

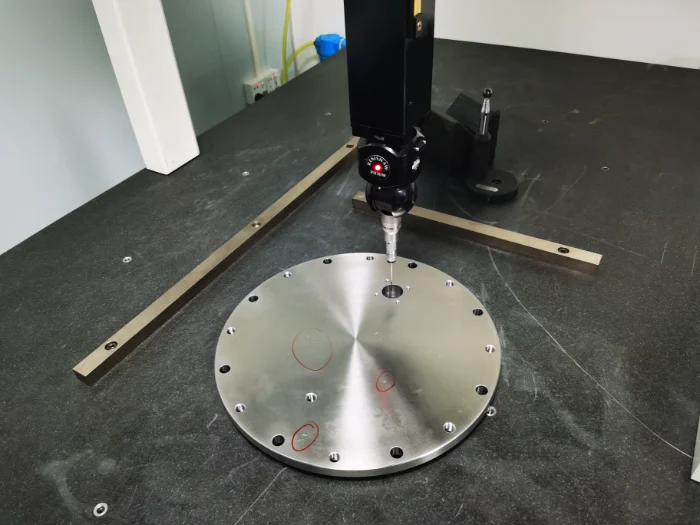

Project Overview

This prototype project involves a synchronizer ring produced using 5 axis CNC machining. The component features a circular ring structure with multiple circumferential holes and functional surfaces, making cnc machining 16MnCr5 prototype an ideal solution for early-stage validation and precision testing,The following are the main machining steps:

CNC Turning of Inner Bore, Outer Diameter, and Datum Faces

Equipment and Tools:

CNC lathe, carbide cutting tools, precision chucking system.

Function and Importance:

This operation establishes the primary machining datums of the part, ensuring concentricity and dimensional stability of the inner bore, outer diameter, and end faces. These reference surfaces provide a precise foundation for subsequent five-axis machining and inspection.

5 Axis CNC Machining of Profiles, Holes, and Circumferential Features

Equipment and Tools:

Five-axis CNC machining center, carbide end mills, tool measurement system.

Function and Importance:

Complex contours, circumferential structures, and hole patterns are completed in a single setup. This approach ensures angular accuracy and positional consistency while eliminating cumulative errors caused by multiple re-clamping operations.

Precision Chamfering and Deburring

Equipment and Tools:

Chamfering end mills, precision deburring tools.

Function and Importance:

Sharp edges and burrs are removed to improve assembly smoothness and operational safety, while ensuring consistent edge quality and long-term component reliability.

PVD (DLC) Coating Treatment

Equipment and Tools:

PVD vacuum coating system, coating thickness measurement equipment.

Function and Importance:

The DLC coating reduces friction, enhances wear resistance, and extends service life. Coating thickness is tightly controlled to ensure no impact on assembly dimensions.

Dimensional, Visual, and Functional Inspection

Equipment and Tools:

Coordinate Measuring Machine (CMM), micrometers, height gauge, optical comparator, and surface roughness tester.

Function and Importance:

Comprehensive inspection verifies dimensional accuracy, geometric tolerances, and surface quality, ensuring full compliance with drawing requirements and assembly standards before delivery.

Machining Requirements Based on Drawing Notes

Material – 16MnCr5 Alloy Steel

The part is made from 16MnCr5, a low-alloy case-hardening steel commonly used in alloy steel CNC machining for transmission components requiring high surface durability and a tough core.

Machining Method – 3D and Five-Axis CNC Machining

The synchronizer ring is processed using 3D machining combined with 5 axis CNC machining, allowing precise milling of both side faces and circumferential features in one setup. This approach is critical for cnc machining 16MnCr5 prototype accuracy.

Surface Treatment – PVD Coating (DLC a-C:H)

The drawing specifies a DLC PVD coating with a thickness of 0.0015 ± 0.001 mm, applied to reduce friction, improve wear resistance, and extend service life of the steel component.

Hole Position and Structural Accuracy

Multiple holes are evenly distributed around the ring. Angular spacing and positional accuracy must be strictly controlled to ensure assembly consistency.

Deburring and Chamfering

All sharp edges are chamfered and deburred to improve safety, assembly performance, and part reliability.

Inspection Requirements

Material certificates and inspection records are required. Finished parts must meet drawing dimensions and tolerances.

Why Use 5 Axis CNC Machining

For this ring-shaped, multi-feature structure, 5 axis CNC machining offers clear advantages in cnc machining 16MnCr5 prototype production:

- Complete complex geometry in a single setup

- Excellent control of concentricity and positional accuracy

- Reduced cumulative errors from re-clamping

- Stable quality for subsequent coating processes

Applications, Components, and Advantages of 16MnCr5

As a low-alloy case-hardening steel, 16MnCr5 is extensively applied in transmission and motion-control systems where wear resistance and durability are critical.

Typical application fields include:

- Automotive manual and automated transmissions

- Industrial gearboxes and reducers

- Precision mechanical drive systems

- Heavy-duty machinery and automation equipment

Common components manufactured from 16MnCr5 include:

- Synchronizer rings

- Gears and pinions

- Gear rings and splines

- Shafts and bushings

Key advantages of using 16MnCr5 in CNC machining prototypes:

- Excellent machinability in the soft (annealed) condition

- High surface hardness after carburizing, ideal for friction components

- Tough and fatigue-resistant core structure

- Stable dimensional behavior when proper machining allowances are applied

- Cost-effective choice for alloy steel CNC machining during prototype and pre-production stages

These advantages make cnc machining 16MnCr5 prototype parts particularly suitable for synchronizer ring development, where both performance validation and manufacturability must be confirmed before scaling to volume production.

Materials Commonly Used for Synchronizer Rings

Selecting the correct material is critical for synchronizer ring performance, especially in cnc machining 16MnCr5 prototype development where functional validation is required before mass production. Synchronizer rings operate under repeated friction, impact loads, and high cycle fatigue, which places strict demands on both surface hardness and core toughness.

Commonly used materials for synchronizer rings include:

- 16MnCr5 (Low-Alloy Case Hardening Steel)

Widely used for precision synchronizer rings due to its excellent balance of machinability, carburized surface hardness, and core toughness. - 20MnCr5

Similar to 16MnCr5 but with slightly higher strength, suitable for heavier-duty transmission systems. - 20CrMo / 20CrMoH

Offers improved hardenability and fatigue resistance, often used in high-load automotive or industrial gearboxes. - 8620 Alloy Steel

A commonly used case-hardening steel in North American markets, suitable for synchronizer rings and gear components. - Powder Metallurgy Steels (PM parts)

Used in some high-volume applications, though typically less flexible for prototype CNC machining.

Among these options, cnc machining 16MnCr5 prototype parts are often preferred during development stages due to cost efficiency, availability, and predictable heat treatment behavior.

Case Summary

This case demonstrates how cnc machining 16MnCr5 prototype manufacturing, combined with 5 axis CNC machining, enables reliable production of synchronizer rings made from alloy steel. Precision machining, controlled surface treatment, and strict inspection ensure functional validation before mass production.if you want to know more details of cnc machining steel part or get a instant quote,please feel free to contact with us Weldo machining now.