Demand for cnc machining 350 brass cost insights continues as brass is widely used in electrical, plumbing, aerospace, and precision parts for its machinability and corrosion resistance.

This guide briefly covers key factors impacting cnc machining 350 brass cost, compares 350 brass alloy cnc machining with other grades, and mentions standards like C36000, C46400, CW614N, CZ121, and CuZn39Pb3 for better alloy and cost planning.

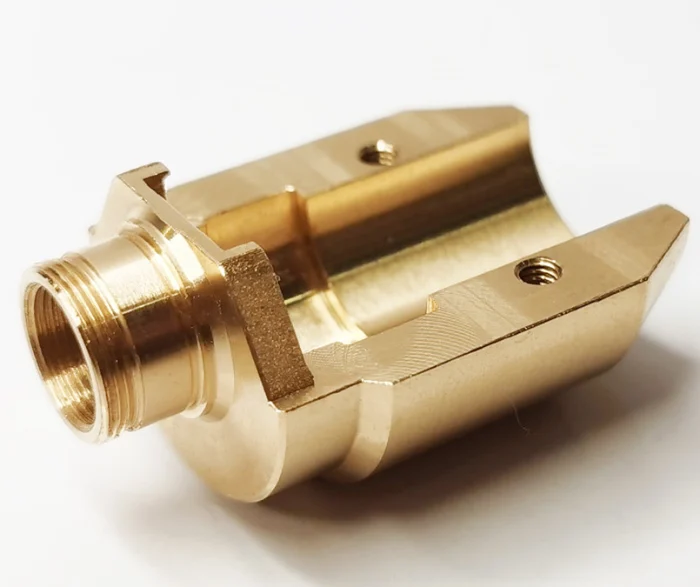

What Is 350 Brass and Why It Matters in CNC Machining

350 brass is a versatile copper-zinc alloy known for:

- Medium strength

- Good corrosion resistance

- Stable machinability

- Affordable material cost

Manufacturers prefer this alloy because cnc machining 350 brass cost remains lower than many aluminum, stainless steel, and bronze materials while still delivering excellent tolerance control.

Applications of 350 Brass

- Electrical contact terminals

- Valves and fluid control parts

- Fasteners and bushings

- Precision gears

- Industrial fittings

- Decorative hardware

These parts benefit from 350 brass alloy cnc machining due to reduced tool wear, smoother cuts, and predictable machining performance.

Key Factors Affecting CNC Machining 350 Brass Cost

Although brass is easier to machine than stainless steel or titanium, several elements influence the total cnc machining 350 brass cost.

1. Raw Material Price

350 brass bar stock typically ranges from $3.50–$6.50 per lb depending on:

- Global copper market

- Diameter and tolerance

- Supplier location

Material cost contributes 15–35% of the total project cost.

2. Machining Complexity

Parts requiring:

- Tight tolerances (±0.001 in)

- Deep cavities

- Thin walls

- Fine threads

- Multi-axis toolpaths

…will increase cnc machining 350 brass cost due to longer spindle time and tool compensation.

3. Quantity

- Prototype (1–5 pcs): highest cost per unit

- Small batch (10–200 pcs): moderate pricing

- Mass production: lowest cost per piece

Brass responds well to high-volume machining, helping reduce per-unit cost.

4. Machinery Type

Different machines impact pricing:

- 3-axis machining: basic, low cost

- 4-axis machining: moderate cost

- 5-axis machining: highest precision & highest rate

Complex parts requiring 5-axis machining push up cnc machining 350 brass cost by 25–40%.

5. Surface Finishing

Common brass finishes:

- Polishing

- Sandblasting

- Nickle plating

- Clear coat

- Passivation

Finishing adds 5–30% to overall machining cost.

Price Range of CNC Machining 350 Brass Components

Pricing varies by geometry, volume, and tolerance.

Typical Cost Breakdown

- Simple turned part: $6–$20

- Moderate complexity: $20–$55

- Precision multi-axis component: $55–$180

- Prototype with tight tolerances: $80–$250+

Thus, understanding cnc machining 350 brass cost helps engineers make informed decisions during product development.

350 Brass Alloy CNC Machining vs Other Global Brass Standards

To better evaluate 350 brass alloy cnc machining, it’s important to compare it with international alloys used in similar applications.

C36000 (Free-Cutting Brass, USA)

- Machinability rating: 100% (industry benchmark)

- Lead content improves tool life

- Applications: high-speed machining, precision fittings

C36000 typically offers slightly lower machining cost than cnc machining 350 brass cost due to superior free-cutting behavior.

C46400 Naval Brass (USA)

- Higher corrosion resistance

- Used for marine valves and high-wear parts

- Harder to machine than 350 brass

Machining cost is usually 10–20% higher.

CW614N / CZ121 (Europe)

- Excellent chip control

- Common in European CNC shops

- Used for plumbing parts, fasteners, aerospace fittings

Machining performance is similar to 350 brass, which means 350 brass alloy cnc machining remains competitive in global markets.

CuZn39Pb3 (International Standard)

- Heavy-duty brass

- Exceptional machinability

- Slightly higher strength

Cost is comparable or slightly higher than cnc machining 350 brass cost depending on hardness range.

Machining Behavior of 350 Brass

Understanding the cutting behavior helps optimize cnc machining 350 brass cost.

Tool Life

350 brass produces:

- Low heat generation

- Minimal tool wear

- Clean chip formation

This results in faster machining cycles and improved tool longevity.

Surface Finish

Most parts achieve:

- Ra 0.8–1.6 µm without secondary finishing

- Ra 0.2–0.4 µm with light polishing

Superior finish quality helps reduce additional surface treatment cost.

Dimensional Accuracy

Typical tolerances achievable:

- ±0.001 in standard

- ±0.0005 in precision components

This makes 350 brass alloy cnc machining ideal for tight-tolerance assemblies.

Ways to Reduce CNC Machining 350 Brass Cost

Engineers and buyers can lower overall machining cost with a few strategies.

Optimize Wall Thickness

Avoid extremely thin walls (<0.6 mm).

Thin walls slow machining and increase failure rate.

Simplify Features

Reduce:

- Deep pockets

- Complex chamfers

- Tiny internal fillets

- Multiple setup requirements

Each simplification directly lowers cnc machining 350 brass cost.

Increase Order Volume

Higher quantity lowers tool change, setup time, and machining cost per unit.

Choose the Right Brass Alloy

C36000 or CW614N may reduce tool load compared with 350 brass, lowering machining cost.

Industries Using 350 Brass CNC Machined Parts

350 brass is widely used across sectors where stability, conductivity, and corrosion resistance are required.

Examples

- Aerospace connectors and bushings

- Automotive precision parts

- Medical device components

- Industrial pumps and valves

- High-quality electrical hardware

- Consumer product mechanisms

The combination of low cnc machining 350 brass cost and stable mechanical performance makes it attractive for mass-production.

Why Choose Weldo Machining for Brass CNC Parts

Weldo Machining offers:

- Advanced 3-axis, 4-axis, and 5-axis machining

- Precision turning for brass fittings and connectors

- Deep experience with 350 brass, C36000, CW614N, CZ121, and CuZn39Pb3

- Tight tolerance control down to ±0.001 in

- Full surface finishing options

- Rapid prototypes and large-scale production

Whether you require complex aerospace fittings or high-volume industrial components, Weldo Machining provides competitive cnc machining 350 brass cost with consistent accuracy and quick turnaround.

Contact us anytime for quotes, samples, or technical support.