Choosing 6082 for precision parts is a smart move—good strength, excellent corrosion resistance, and clean finishes. But procurement teams and engineers often struggle to forecast CNC machining 6082 aluminum cost with confidence. This guide breaks the price drivers into a practical “cost stack,” then shows how to de-risk quotations and lower CNC machining 6082 aluminum cost without compromising quality.

Cost Stack Level 1: Material Cost and Stock Strategy

A surprising portion of CNC machining 6082 aluminum cost is decided before a tool touches metal.

Material Grade, Form, and Temper

- 6082 typically ships in T6/T651. T651, being stress-relieved, improves dimensional stability—often reducing scrap and rework, which lowers the effective CNC machining 6082 aluminum cost.

- Plate vs. bar vs. extrusion: Plate stock may carry a higher sticker price but can reduce prep time and fixturing.

Stock Utilization and Nesting

- Oversized blanks drive up material cost and chip volume. Optimizing blank size, adding tabbing, or switching to near-net extrusions can cut raw price and shorten cycle time.

- Ask suppliers for nesting plans on multi-part plates; better yield translates directly to lower CNC machining 6082 aluminum cost.

Cost Stack Level 2: Machining Time—The Dominant Driver

Machining time is the most powerful lever for controlling CNC machining 6082 aluminum cost.

Toolpaths and Cutter Choices

- 6082 machines well with carbide end mills and high-efficiency milling (HEM) strategies. Stable tool engagement allows higher MRR, reducing price per part.

- Chip evacuation is friendly compared with 7075; dialed-in coolant and step-over let you keep surface finish while maintaining fast feeds.

Setup and Fixturing

- Modular vises and zero-point systems compress setup minutes, which matter a lot in small batch runs.

- If the part requires flips, consider 4-/5-axis workholding; fewer re-clamps reduce human time and scrap—again improving CNC machining 6082 aluminum cost.

Cost Stack Level 3: Tolerance Requirements and GD&T Scope

Tolerances quietly reshape CNC machining 6082 aluminum cost.

- Features at ±0.02 mm vs. ±0.10 mm can double finishing passes and inspection time.

- Tight flatness or position callouts on thin walls may require stress-relief or intermediate rest-machining, increasing machining time and price.

- Align functional surfaces with realistic GD&T. Label everything else “reference” or use wider bands; this often trims 10–20% from the CNC machining 6082 aluminum cost.

Cost Stack Level 4: Surface Treatment and Dimensional Planning

Surface treatment is frequently underestimated when forecasting CNC machining 6082 aluminum cost.

- Type II anodizing: economical, cosmetic, corrosion-resistant.

- Hardcoat (Type III): superior wear resistance but a higher price and thickness impact; design for growth (both sides) to avoid rework.

- Bead blast + anodize improves cosmetic consistency on 6082 and hides machining marks; include it in the quotation so it’s planned, not a surprise.

Cost Stack Level 5: Batch Quantity and Economies of Scale

Batch quantity is the classic lever on CNC machining 6082 aluminum cost.

- One-time setups amortize dramatically.

- Programs, fixtures, and inspection routines are reusable.

- Tooling can shift from “general-purpose” to process-optimized once volumes justify inserts or custom form tools.

Indicative Cost Curves (for a mid-complexity plate part)

| Quantity (pcs) | Cost per Part (USD) | What Changes |

|---|---|---|

| 1–5 | 120–240 | One-off setup, slower toolpaths, manual deburr |

| 25–100 | 45–95 | Optimized CAM, fixtures, grouped anodizing |

| 250–1000 | 20–55 | Lights-out runs, bulk price on material, automated QC sampling |

These are directional only, but they reflect how batch quantity resets the baseline CNC machining 6082 aluminum cost.

From Drawing to Number: Building a Quote that Sticks

A clean estimate prevents change orders and protects the project timeline. Provide your supplier with:

- Manufacturable STEP/IGS plus a fully dimensioned PDF drawing.

- GD&T clearly separating critical features from cosmetic ones.

- Material spec (6082-T6 vs. T651) and acceptable substitutions, if any.

- Surface treatment details (finish type, color, masked zones).

- Batch plan: prototype now, production later—state both.

- Delivery target and packaging expectations.

Clarity here compresses the quotation cycle and reduces risk premia baked into CNC machining 6082 aluminum cost.

5 High-Impact Design Levers to Cut CNC Machining 6082 Aluminum Cost

1) Consolidate Setups

Add a datum strategy that allows two-sided completion with minimal flips. Every eliminated flip reduces machining time and fixture complexity.

2) Standardize Radii

Match internal corner radii to standard tool sizes (e.g., ≥ R2.0 mm). Avoid tiny end mills unless absolutely necessary.

3) Adjust Wall Thickness

Ultra-thin walls chatter and warp. Bumping from 1.0 mm to 1.5 mm may halve finishing passes and slash CNC machining 6082 aluminum cost.

4) Tolerance Tiering

Place ±0.02 mm only where function demands; widen others. Your price falls with every eased feature.

5) Finish with Purpose

Pick the least costly surface treatment that meets requirements. For non-wear parts, Type II anodize often suffices.

Risk Map: Hidden Drivers That Distort Price

- Residual stress in large plates can move features during finishing. Use T651 when possible and plan semi-finish passes.

- Tool reach on deep pockets forces small cutters; consider design reliefs or split features.

- Change creep—late drawing revisions raise the final CNC machining 6082 aluminum cost more than any single parameter; freeze a rev for quoting.

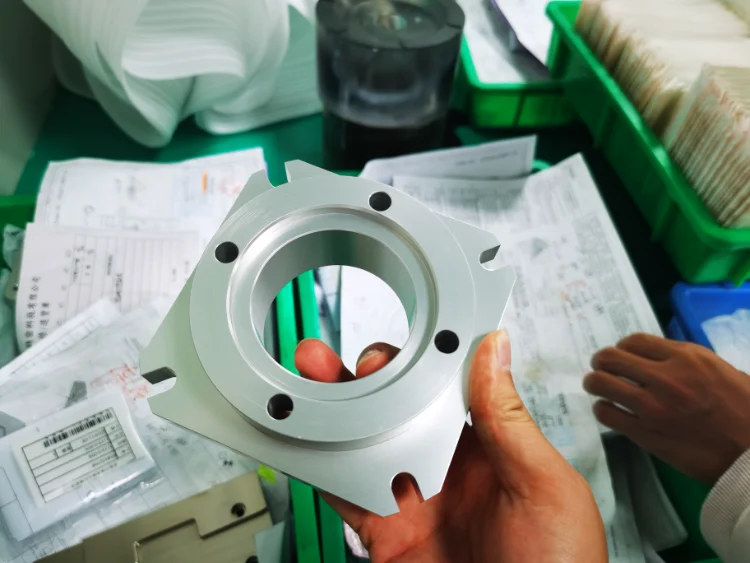

Case Snapshot: Automation Housing in 6082-T651

- Envelope: 180×120×35 mm, pocketed, threaded inserts

- Critical tolerance: ±0.03 mm flatness on mounting face

- Finish: bead blast + black Type II anodize

- Batches: 15 pcs prototype → 300 pcs production

Outcomes

- Prototype price: USD 118/part (single fixture, conservative feeds)

- Production price: USD 47/part (optimized toolpaths, zero-point fixturing)

- Scrap rate under 1%; stable anodize color with masked threads

The delta shows how process learning and volume reposition CNC machining 6082 aluminum cost.

Supplier Playbook: What to Expect from a Cost-Focused Partner

A capable partner should help you reduce CNC machining 6082 aluminum cost proactively:

- DFM reviews within 24–48 hours, with quantified savings.

- CAM simulation screenshots that explain cycle time.

- Material certificates and traceable batches for 6082-T6/T651.

- In-house or integrated surface treatment to avoid freight delays.

- Clear lead-time tiers (prototype vs. production) and consolidated packaging.

Why Weldo Machining for CNC Machining 6082 Aluminum Cost Control

Weldo Machining combines process engineering with transparent quoting to systematically lower CNC machining 6082 aluminum cost:

- Optimized HEM strategies and balanced tool libraries for 6082.

- Tolerance tiering support to protect function and reduce machining time.

- In-house bead blast, coordinated anodizing, and dimensional QA.

- Prototyping in days, scaled batch quantity runs with stable cost curves.

Send your STEP and PDF today—we will return a line-item quotation with options that let you choose the best price-to-performance path.

Conclusion

Understanding the “cost stack” transforms CNC machining 6082 aluminum cost from a mystery into a controllable set of levers: material cost, machining time, tolerance requirements, surface treatment, and batch quantity. When these are engineered together, high-quality parts arrive on time and on budget.

If you want a fast, defensible price for your next 6082 project—and a partner who actively engineers cost out—Weldo Machining is ready to help. Share your files and target volumes, and we will provide an optimized quotation and DFM plan.