When strength, machinability, and corrosion resistance come together, aluminum alloy 6082 becomes a top contender for engineers and buyers. But choosing the right CNC machining 6082 aluminum factory isn’t just about capacity—it’s about technical know-how, consistency, and quality.

In this article, we’ll explore what makes a great factory stand out in CNC machining 6082 aluminum, how to evaluate a manufacturer’s capabilities, and why sourcing from the right supplier or company can make or break your project.

Why Aluminum 6082 Is Gaining Popularity in CNC Machining

Before diving into supplier selection, let’s understand why aluminum 6082 is so frequently requested by engineers.

What Is 6082 Aluminum?

6082 is a medium-strength alloy in the 6000 series, composed primarily of aluminum, magnesium, and silicon. It offers:

- Excellent corrosion resistance

- High structural strength

- Superior surface finish post-machining

- Weldability (better than 7075 or 2024)

It’s ideal for industrial aluminum parts, frames, transportation components, and marine equipment—making it a staple for many CNC machining companies.

What Makes a Great CNC Machining 6082 Aluminum Factory?

Not all factories that offer CNC services are specialists in machining 6082 aluminum alloy. Here’s what sets a professional CNC machining 6082 aluminum manufacturer apart:

Specialized Knowledge in 6082 Machining

Aluminum 6082 has good machinability, but optimal results require:

- Correct cutting tools (e.g., carbide inserts)

- Lubrication control to avoid burring

- Speed/feed rates tailored to the hardness (especially T6 temper)

Experienced factories understand these nuances and deliver high precision machining without quality defects.

Full-Service Workflow from Prototype to Production

A modern CNC machining 6082 aluminum factory should handle:

- CAD/CAM design support

- Rapid prototyping

- Batch production (low to high volume)

- Surface treatment (like anodizing, polishing)

This one-stop solution saves time, avoids communication errors, and ensures quality continuity across production stages.

Material Sourcing: Why It Matters Who Supplies the 6082 Aluminum

When selecting a CNC company or factory, always ask about raw material sourcing. Not all 6082 aluminum is created equal. A qualified supplier should offer:

- Traceable material certificates (EN, ASTM, ISO)

- Availability in different forms (plate, rod, extrusion)

- Options for T4, T5, T6 tempers

Substandard material affects final strength, surface finish, and machinability. A trustworthy CNC machining 6082 aluminum company only works with verified material sources.

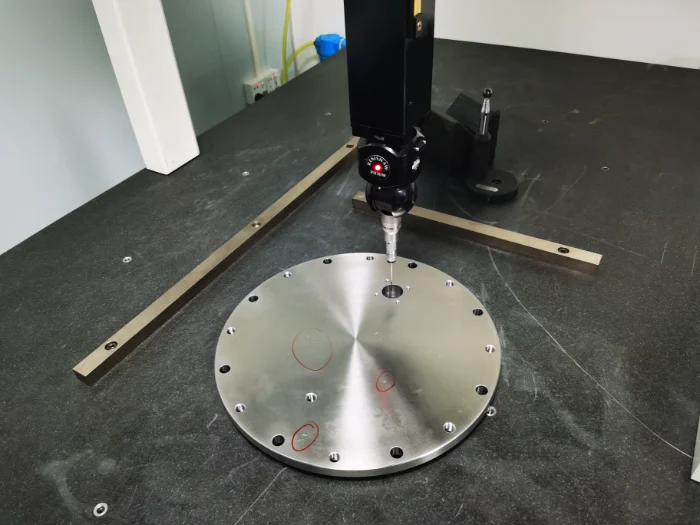

Precision Matters: Tolerances & Quality Control

Many clients choose 6082 for parts that require ±0.01 mm tolerances or better, especially for:

- Mounting plates

- Enclosures

- Sliding mechanisms

- High-speed assembly equipment

A qualified factory should provide:

- CMM inspection (coordinate measuring machine)

- Process control documentation

- In-house or third-party dimensional reports

If you’re working on aerospace, automation, or automotive projects, ask your manufacturer if they support FAI (First Article Inspection) and batch sampling.

Surface Treatment Capabilities: Beyond Raw Machining

Most end-users don’t want raw aluminum—they want a finished product. That’s why your CNC machining 6082 aluminum supplier should offer surface treatment services such as:

- Anodizing (clear, black, hard anodizing)

- Bead blasting (matte finishes)

- Powder coating or chromate conversion coating

These finishes protect the part and enhance its appearance, but they also impact final dimensions—so your factory should account for coating thickness during machining.

Domestic vs. Overseas: Where Should You Source CNC 6082 Parts?

Both local and international CNC factories have pros and cons. Here’s a comparison:

| Criteria | Local Factory (e.g., U.S., EU) | Overseas Factory (e.g., China) |

|---|---|---|

| Lead Time | Shorter for low-volume | Slightly longer, unless expedited |

| Pricing | Higher (labor, material) | More cost-effective |

| Capabilities | Often specialized | Broad range, full-service |

| Scalability | Limited | High scalability |

| Certifications | Easier to verify | Ask for ISO, EN docs |

A global CNC machining 6082 aluminum supplier like Weldo Machining offers the best of both—international pricing with consistent QA, DFM support, and fast DHL/UPS shipping.

Questions to Ask Your CNC Machining 6082 Aluminum Company

To avoid miscommunication and quality issues, ask these questions before placing an order:

- Do you regularly machine 6082 aluminum?

- Can you provide samples of similar projects?

- What are your typical tolerances and finishes?

- Do you offer full QA reports or CMM inspection?

- What is your average lead time for 100 pcs?

- Are surface treatments included in your quote?

A serious manufacturer will respond clearly and promptly, showing experience and transparency.

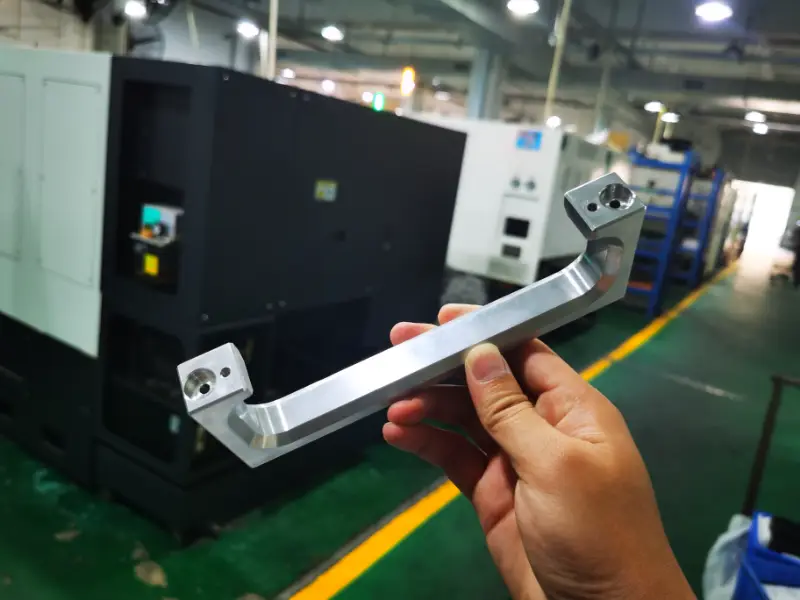

Real-World Example: 6082 Aluminum Bracket Project

Let’s look at a real use case handled by a CNC machining 6082 aluminum factory:

Project: Custom mounting bracket for industrial robotics

Material: 6082-T6 aluminum

Process: CNC milling + bead blast + black anodizing

Qty: 250 pcs

Tolerances: ±0.02 mm on hole diameter, ±0.05 mm overall

Delivery: 15 working days

Result:

- Passed QC with 98% yield

- Full QA report delivered

- Client reorder volume increased to 1,000 pcs

This is a typical job that a capable supplier or company like Weldo can handle from quote to delivery—on time and on spec.

Why Work with Weldo Machining?

At Weldo Machining, we specialize in CNC machining 6082 aluminum with full-stack services from DFM to finishing. Whether you need prototypes or full-scale production, we deliver:

- High-precision CNC parts in 6082, 6061, 7075, and more

- Material certification and traceability

- Surface treatment integration

- Global shipping and competitive pricing

- Support for industrial, aerospace, and automation applications

Contact us today for a free consultation or to request a quote for your next aluminum project.