In today’s fast-paced world of high-performance engineering, CNC machining 7075 aluminum has become the preferred solution for industries demanding strength, precision, and lightweight efficiency. From aerospace components to high-performance automotive parts, this alloy consistently delivers. But what makes 7075 aluminum such a standout? And why does it pair so well with CNC machining?

Let’s explore its unique advantages, applications, surface finishes, and cost considerations to help engineers, designers, and procurement teams make informed decisions.

7075 Aluminum in CNC Machining: Why It’s the Engineer’s Favorite

At the heart of CNC machining 7075 aluminum lies its exceptional mechanical properties. This high-strength aluminum alloy—primarily composed of zinc, magnesium, and copper—offers:

- Ultimate tensile strength of up to 83,000 psi

- Excellent fatigue resistance

- Good machinability, especially in tempers like T6 and T651

Its strength-to-weight ratio makes it an ideal material for applications that demand precision tolerances without sacrificing durability.

Engineers in the aerospace, defense, and motorsports sectors often turn to 7075 aluminum because it can withstand both static and dynamic stress in extreme conditions.

From Aerospace to Robotics: Applications of CNC Machined 7075 Aluminum

When we talk about CNC machining 7075 aluminum, we’re really talking about a material that serves some of the most demanding industries in the world:

1. Aerospace Components

Because of its high tensile strength and low weight, 7075 is a staple in aerospace components such as:

- Structural wing elements

- Fuselage frames

- Landing gear parts

These parts must endure fluctuating stresses, and CNC machining ensures the exacting tolerances required by aerospace standards.

2. Motorsport and Performance Racing

7075 aluminum is widely used for:

- Suspension systems

- Gearbox housings

- Wheel hubs

These parts benefit from CNC machining 7075 aluminum due to its vibration damping characteristics and lightweight performance.

3. Robotics and Automation Equipment

In high-speed pick-and-place systems, CNC machined 7075 components provide reduced inertia and longer system lifespan.

4. Mold Tooling and Fixtures

Though not as common as tool steels, 7075 aluminum is occasionally used for short-run molds or quick-turn fixtures where weight and turnaround time are critical.

Machining Behavior: How 7075 Aluminum Performs Under CNC

High-Speed Machining Capabilities

Due to its favorable chip formation and thermal conductivity, CNC machining 7075 aluminum allows high RPM and feed rates without sacrificing surface quality.

Tool Selection and Wear

Despite being harder than 6061, 7075 is still considered machinable. Carbide tools are recommended, and proper coolant use reduces tool wear, especially during tight-tolerance finishing passes.

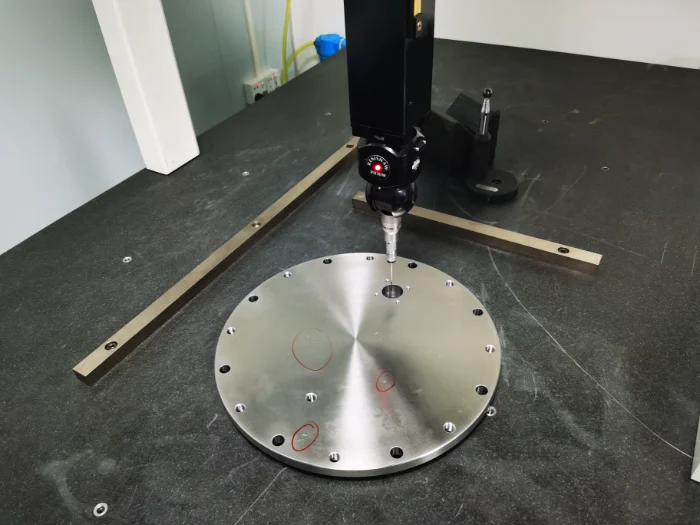

Precision Tolerances and Surface Finishing

Standard tolerances of ±0.005 inch are achievable on basic features, but with fine-tuning, CNC machines can reach ±0.001 inch on critical geometries. This makes it ideal for parts where precision tolerances are essential, such as mating surfaces or bearing seats.

Surface Treatments: Anodizing and More for 7075 Parts

Post-machining, 7075 aluminum is highly receptive to a variety of finishes, enhancing both appearance and corrosion resistance.

Anodizing 7075 Aluminum

- Type II anodizing offers decent corrosion resistance and color options.

- Type III hard coat anodizing enhances wear resistance but requires close control, as 7075’s copper content can make it prone to pitting.

Anodizing is a critical consideration for CNC machining 7075 aluminum, especially for aerospace or marine parts.

Other Surface Treatments

- Chromate conversion coating (Alodine) for conductivity

- Teflon or nickel coatings for friction-sensitive parts

These finishes not only protect the part but also contribute to its final dimensions—requiring compensation in the CNC machining stage.

Comparing 7075 to Other Aluminum Alloys

| Alloy | Strength | Corrosion Resistance | Processability | Cost |

|---|---|---|---|---|

| 7075 | Very High | Moderate | Good | High |

| 6061 | Medium | High | Excellent | Lower |

| 2024 | High | Low | Good | Moderate |

While 6061 is cheaper and easier to anodize, it simply can’t compete with the strength and stiffness of CNC machined 7075 aluminum in structural applications.

Cost Considerations: What’s the Real Price of CNC Machining 7075 Aluminum?

When calculating cost per part, several factors come into play:

1. Material Cost

7075 aluminum is roughly 30–40% more expensive than 6061 due to its alloying elements and heat treatment.

2. Machining Time

Though relatively machinable, harder alloys can slightly increase cycle time and tool wear—especially on tight-tolerance features.

3. Surface Finishing Costs

Anodizing 7075 aluminum typically costs more than with 6061 due to its copper content. Complex masking or fixturing can further raise costs.

4. Batch Volume

As with all CNC parts, larger batch sizes reduce cost per part due to setup amortization.

In short, CNC machining 7075 aluminum may not be the cheapest option—but its performance value often justifies the investment.

Conclusion: When Precision Demands Strength, Choose CNC Machining 7075 Aluminum

Whether you’re designing high-load aerospace components or lightweight robotic arms, CNC machining 7075 aluminum delivers the performance you need. Its superior strength-to-weight ratio, high fatigue resistance, and clean machinability make it a champion in advanced manufacturing.

At Weldo Machining, we specialize in custom CNC projects using 7075 aluminum and other high-performance materials. With state-of-the-art 5-axis machines and precision QA systems, we deliver tight-tolerance parts with fast lead times.

Contact us today to discuss your next 7075 aluminum project, request a quote, or learn more about optimal design for CNC manufacturing.