When your project demands strength, precision, and lightweight performance, 7075 aluminum is often the material of choice. But selecting the right CNC machining 7075 aluminum supplier isn’t just about capability—it’s about trust, consistency, and technical depth.

Whether you’re prototyping aerospace brackets or producing thousands of custom CNC parts, this guide helps you evaluate and choose a reliable supplier, manufacturer, or company to handle your high-spec aluminum machining needs.

Why 7075 Aluminum Needs a Specialized CNC Supplier

Not all CNC suppliers are created equal. 7075 aluminum is one of the strongest commercially available aluminum alloys, with excellent fatigue resistance and a high strength-to-weight ratio. It’s widely used for:

- Aerospace-grade aluminum components

- High-load structural parts

- Racing and defense equipment

- Robotic assemblies

However, its hardness, thermal expansion, and susceptibility to stress cracking mean that working with it requires specific tooling, experience, and often tight tolerance machining. That’s why choosing a specialized CNC machining 7075 aluminum supplier is critical.

Core Capabilities to Look for in a 7075 Aluminum CNC Company

Material Expertise in 7075-T6 / T651

A qualified 7075 aluminum machining supplier should understand the temper variants of the alloy and how they affect machining and post-processing. For example, T651 is stress-relieved and preferred for parts requiring dimensional stability.

Ask if the supplier provides material certifications and traceability—this is especially important for aerospace or defense-related projects.

Tight Tolerance CNC Machining Capabilities

7075 aluminum is often used in parts requiring tolerances of ±0.001–0.002 inch. Look for suppliers that offer:

- 3-, 4-, and 5-axis machining

- In-house CMM inspection or laser scanning

- DFM support (design for manufacturability)

- Process validation for small batch production

A CNC company that handles precision parts daily will be more efficient and reliable.

Surface Finishing and Anodizing Services

Because raw 7075 aluminum is vulnerable to corrosion, many parts require anodizing service post-machining. Look for suppliers that can offer:

- Type II anodizing (standard colors)

- Type III hard anodizing (durability)

- Alodine or chromate conversion coating

- Masking for selective finishing

Working with a CNC supplier who integrates finishing in-house saves time and cost.

Signs of a Trusted CNC Machining 7075 Aluminum Manufacturer

Choosing a CNC supplier is more than a technical checklist—it’s about forming a reliable, transparent partnership. Evaluate the following attributes:

Proven Industry Experience

Does the supplier have experience serving your industry—whether aerospace, automotive, or robotics? A reputable CNC machining 7075 aluminum manufacturer should provide:

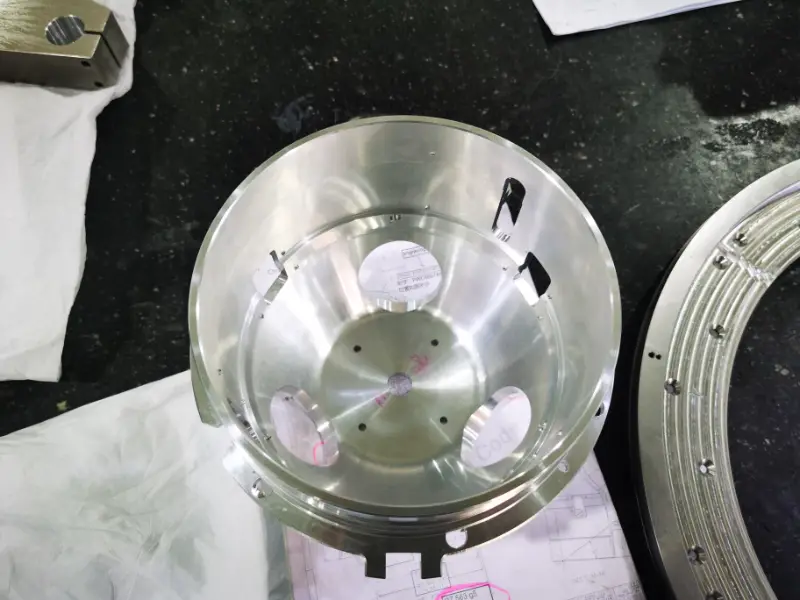

- Case studies or project references

- Sample parts or photos

- Knowledge of industry-specific tolerances, such as AS9100, ISO 2768, or NADCAP standards

Custom CNC Parts Support

If your project involves custom CNC parts, the supplier should be able to:

- Work from complex 3D CAD files (STEP, IGES, SolidWorks)

- Suggest DFM improvements to reduce cost

- Offer prototype + production scaling under one roof

This is especially valuable when moving from early-stage R&D to market launch.

Flexible Production Volumes

Whether you need 10 pieces or 10,000, your CNC machining 7075 aluminum company should offer flexibility in small batch production and high-volume orders alike.

Check for:

- Rapid prototyping support

- MOQ transparency

- Lead time estimates by volume tier.

Cost Transparency and Lead Times

An experienced 7075 aluminum CNC supplier will provide clear, fast quotes with breakdowns for:

- Material cost (based on alloy pricing and size)

- Machining time

- Finishing or anodizing

- Inspection and packaging

Expect lead times of:

- 5–7 working days for prototypes

- 10–15 days for low-volume production

- 20+ days for large-scale projects (depending on complexity)

Working with Overseas vs. Local CNC Suppliers

Should you choose a domestic or international CNC partner?

Local Supplier (e.g., U.S.-based)

✅ Faster communication

✅ Easier logistics and returns

❌ Higher labor and operating costs

Overseas Supplier (e.g., China-based like Weldo)

✅ Competitive pricing

✅ Scalable capacity

✅ Integrated services (machining + anodizing + QA)

❌ Longer shipping lead time (but manageable with DHL/FedEx)

At Weldo Machining, we bridge the gap by combining China’s cost-efficiency with U.S.-style quality communication—ideal for global buyers of custom CNC parts in 7075 aluminum.

Checklist for Choosing Your CNC Machining 7075 Aluminum Supplier

Here’s a quick checklist when evaluating potential partners:

| Criteria | Must-Have |

|---|---|

| Works regularly with 7075-T6/T651 | ✅ |

| Offers 3–5 axis CNC milling | ✅ |

| Supports anodizing / surface finishing | ✅ |

| Accepts custom 3D CAD files | ✅ |

| Can provide material certs + tolerances | ✅ |

| Handles prototype to production scale | ✅ |

| Competitive pricing for small batches | ✅ |

Conclusion: Your Ideal CNC Machining 7075 Aluminum Supplier Awaits

Choosing a CNC partner isn’t just about who can machine 7075—it’s about who can do it right, consistently, and cost-effectively. A qualified CNC machining 7075 aluminum supplier should offer more than just machining—they should provide full-cycle support from CAD file to finished component.

Weldo Machining specializes in 7075 aluminum CNC parts for demanding industries. With over 10 years of experience, in-house finishing, and tight-tolerance capability, we’re trusted by clients across the U.S., Europe, and Asia.

Reach out today to get a free DFM review or a quick quote for your next project.