Selecting a qualified cnc machining aerospace parts manufacturer is a critical decision for aerospace OEMs, Tier 1 suppliers, and engineering teams. Aerospace components demand extreme precision, material consistency, strict quality control, and full process traceability. This page explains what defines a professional aerospace CNC machining service provider, the main aerospace parts and requirements, typical price ranges, key production challenges, and how experienced manufacturers address these challenges effectively.

What Is a CNC Machining Aerospace Parts Manufacturer?

A cnc machining aerospace parts manufacturer is a specialized machining service provider focused on producing precision components for aircraft, spacecraft, UAVs, and aerospace ground equipment using CNC milling, CNC turning, and multi-axis machining technologies.

Unlike general CNC suppliers, aerospace manufacturers must comply with:

- Tight dimensional tolerances

- Aerospace-grade materials

- Process documentation and traceability

- Consistent repeatability across batches

Typical services include CNC milling (3-axis to 5-axis), CNC turning, mill-turn machining, and secondary operations such as surface treatment and inspection.

CNC Machining Service Providers for Aerospace Applications

Aerospace CNC machining service providers usually fall into three categories:

General CNC Machining Shops

- Limited aerospace experience

- Basic tolerance control

- Suitable mainly for non-critical parts

Specialized Aerospace CNC Machining Manufacturers

- Familiar with aerospace materials and drawings

- Strong quality and inspection capability

- Suitable for flight-critical and structural components

Engineering-Driven CNC Machining Partners

- Offer DFM feedback and process optimization

- Focus on long-term production stability

- Support prototype to batch production

For aerospace programs, choosing a professional cnc machining aerospace parts manufacturer with proven industry experience is essential.

Main Aerospace Parts Machined by CNC and Their Requirements

Structural Aerospace Components

Examples:

- Brackets and mounting blocks

- Structural frames

- Housings and supports

Requirements:

- High strength-to-weight ratio

- Aluminum alloys (6061, 7075), titanium, stainless steel

- Tight tolerances (±0.01 mm or better)

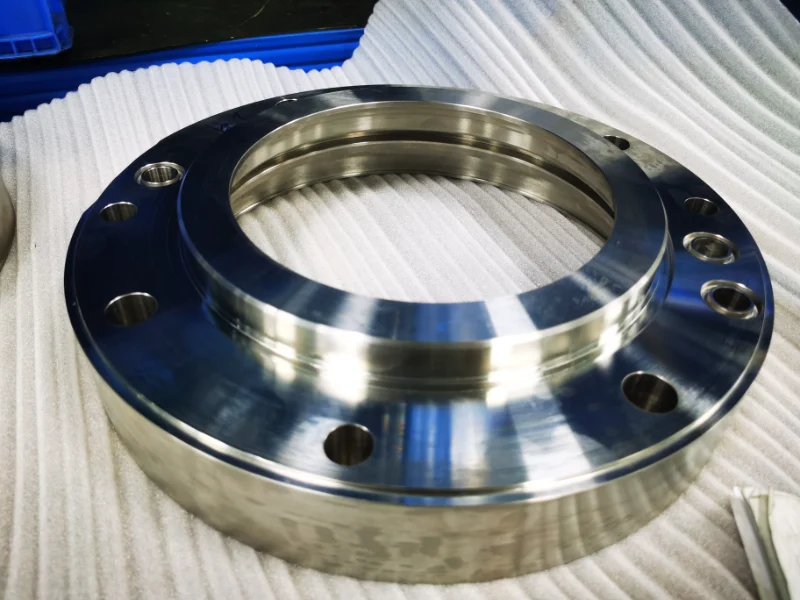

Engine and Power System Parts

Examples:

- Housings

- Flanges

- Precision interfaces

Requirements:

- Heat resistance

- Stable dimensional accuracy

- Advanced machining strategies

Aerospace Precision Components

Examples:

- Bushings

- Shafts

- Precision connectors

Requirements:

- Excellent surface finish

- Consistent batch accuracy

- Strict inspection control

A capable cnc machining aerospace parts manufacturer must understand how part function dictates machining strategy.

Aerospace CNC Machining Price Ranges (Reference Only)

Pricing varies depending on material, tolerance, complexity, and quantity. Typical reference ranges:

- Simple aluminum aerospace brackets: USD 30–80 per piece (low volume)

- Complex 5-axis aerospace parts: USD 120–400+ per piece

- Titanium or hard-to-machine alloys: 20–50% higher than aluminum

A professional cnc machining aerospace parts manufacturer focuses on process optimization, not just unit price, to reduce total project cost.

Basic Requirements for Aerospace CNC Machining Manufacturers

Precision and Tolerance Control

Aerospace parts often require:

- ±0.01 mm or tighter tolerances

- Stable CNC equipment

- Advanced fixturing and tooling

Material Traceability

Aerospace machining requires:

- Certified raw materials

- Batch traceability

- Controlled storage and handling

Inspection and Quality Control

- First Article Inspection (FAI)

- In-process inspection

- Final dimensional verification

Without these fundamentals, a cnc machining aerospace parts manufacturer cannot support aerospace programs reliably.

Production Experience in Aerospace CNC Machining

Experience significantly affects production outcomes. An experienced cnc machining aerospace parts manufacturer understands:

- How different aerospace materials behave under machining stress

- How to avoid deformation in thin-wall structures

- How to maintain repeatability across multiple batches

Production experience reduces scrap rates, delays, and rework costs—critical factors in aerospace manufacturing.

Common Aerospace CNC Machining Challenges and Solutions

Challenge 1: Thin-Wall Deformation

Solution:

- Optimized cutting parameters

- Custom fixturing

- Multi-step roughing and finishing strategies

Challenge 2: Hard-to-Machine Materials

Solution:

- Specialized tooling and coatings

- Controlled cutting speed and feed

- Efficient cooling strategies

Challenge 3: Tight Tolerance Consistency

Solution:

- Process control documentation

- Tool wear monitoring

- Layered inspection systems

An experienced cnc machining aerospace parts manufacturer builds solutions into the process, not after defects occur.

Weldo Machining Compared with Typical Aerospace CNC Suppliers

Weldo Machining is a professional CNC machining service provider supporting aerospace-related components with an engineering-driven approach.

Weldo Machining Overview

- CNC milling and CNC turning for aerospace parts

- Multi-axis machining capability

- Experience with aluminum, stainless steel, and titanium

- Support from prototype to batch production

Comparison Overview

| Aspect | Typical CNC Supplier | Weldo Machining |

|---|---|---|

| Aerospace Experience | Limited or mixed | Focused project experience |

| Engineering Support | Basic | DFM and process optimization |

| Tolerance Control | Standard | Tight and repeatable |

| Communication | Reactive | Clear and structured |

| Scalability | Limited | Prototype to production |

Weldo Machining positions itself as a reliable aerospace CNC machining partner, not merely a job shop.

How to Choose the Right CNC Machining Aerospace Parts Manufacturer

When evaluating suppliers, aerospace buyers should consider:

- Proven aerospace machining experience

- Material and process traceability

- Inspection capability and documentation

- Engineering communication and responsiveness

- Long-term production stability

A dependable cnc machining aerospace parts manufacturer supports both technical and supply-chain requirements.

Conclusion: Partner with the Right Aerospace CNC Machining Manufacturer

Choosing the right cnc machining aerospace parts manufacturer directly impacts performance, safety, and delivery reliability. Aerospace projects demand precision, experience, and disciplined process control. By working with a manufacturer that understands aerospace requirements and invests in engineering support, companies can significantly reduce manufacturing risk.

If you are looking for a capable and responsive aerospace CNC machining partner, Weldo Machining is ready to support your project. Contact Weldo Machining to discuss your aerospace parts, receive professional feedback, and request a competitive CNC machining quotation.