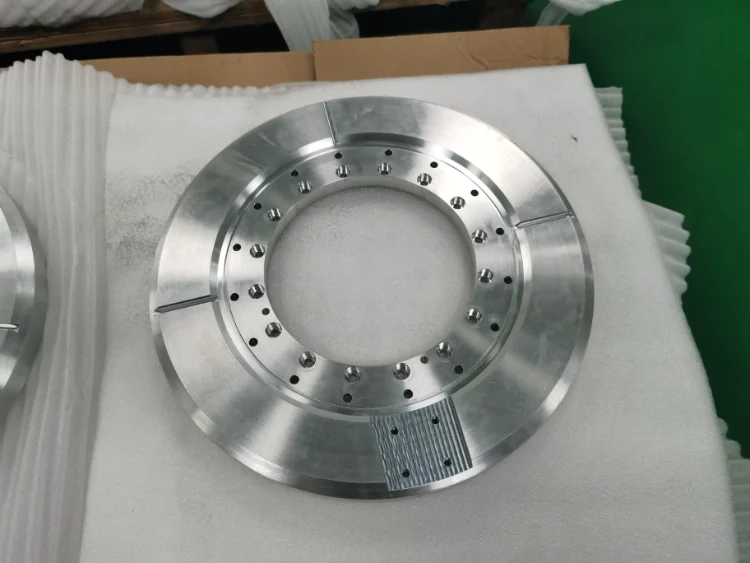

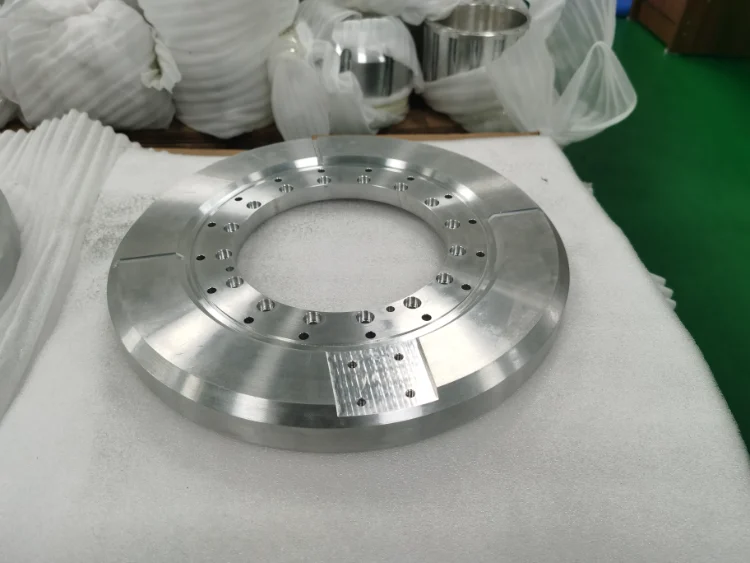

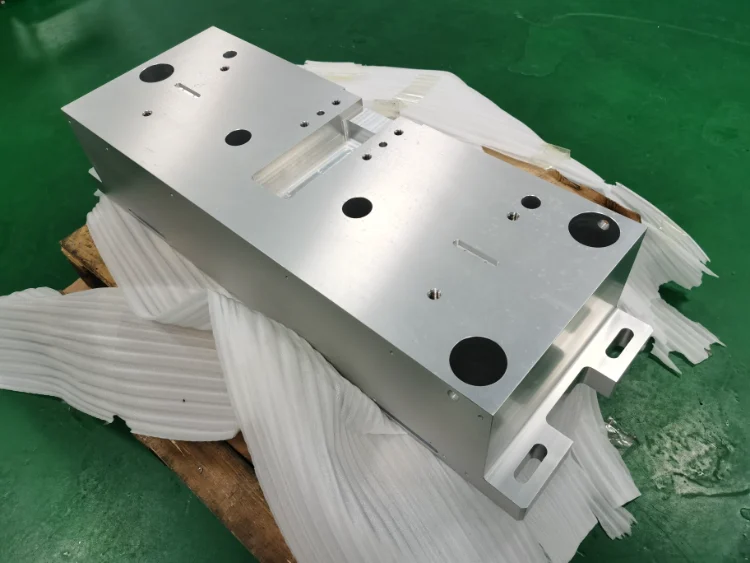

Developing accurate and durable cnc machining aluminum prototypes is essential for product engineers, startups, and manufacturers aiming to validate designs quickly and efficiently. Aluminum is one of the most versatile prototype materials due to its light weight, strength, thermal stability, and excellent machinability. This article explains materials, application fields, common accessories, and factors that influence prototype quality and cost.

Why CNC Machining Aluminum Prototypes Are Essential for Product Development

High-quality cnc machining aluminum prototypes are widely used during product design, performance testing, engineering optimization, and functional validation. Aluminum offers the perfect balance of strength and workability, making it ideal for prototypes requiring structural rigidity and surface precision.

Advantages of Aluminum Prototyping

- Easy to machine and polish

- Strong yet lightweight

- Excellent heat dissipation

- Good corrosion resistance

- Supports tight tolerances and fine surface finishes

Because of these benefits, industries often work with an experienced aluminum cnc machining supplier to ensure consistent prototype performance.

Aluminum Materials Used for CNC Machining Aluminum Prototypes

Different aluminum grades offer distinct mechanical properties. Selecting the right grade is essential for achieving optimal prototype performance.

1. Aluminum 6061

Features

- Most widely used general-purpose aluminum

- Good strength-to-weight ratio

- Excellent machinability

Applications

- Electronic housings

- Industrial brackets

- Machinery components

2. Aluminum 7075

Features

- High strength comparable to mild steel

- Excellent fatigue resistance

Applications

- UAV parts

- Automotive performance components

- Structural aerospace prototypes

3. Aluminum 5052

Features

- Superb corrosion resistance

- Great for bending and folding operations

Applications

- Enclosures

- Marine equipment

- Sheet-metal style prototypes

4. Aluminum 6082

Features

- Improved hardness compared to 6061

- Popular in Europe for load-bearing parts

Applications

- Industrial fixtures

- Automation brackets

- Robotic frames

When working with heavy-duty applications, manufacturers often rely on aluminum alloy cnc machining to ensure structural reliability.

Applications of CNC Machining Aluminum Prototypes Across Industries

Because aluminum is strong yet lightweight, cnc machining aluminum prototypes are widely used across multiple high-performance industries.

Automotive

- Engine brackets

- Chassis prototypes

- Transmission housings

- Heat exchangers

Aerospace & UAV Systems

- Drone frames

- Satellite components

- Aircraft interior fixtures

High-tolerance machining is often provided by a specialized cnc machining aluminum parts factory.

Electronics & Consumer Devices

- Laptop shells

- LED housings

- Cooling plates

- Battery enclosures

Aluminum helps manage heat and provides sleek aesthetics.

Robotics & Automation

- Robot joints

- Motor bases

- Sensor brackets

- Structural arms

Medical & Laboratory Equipment

- Surgical tool housings

- Diagnostic machine covers

- Precision medical fixtures

Common Accessories & Components Used in CNC Machining Aluminum Prototypes

CNC-machined aluminum prototypes often integrate multiple accessories to support assembly, alignment, and testing.

1. Threaded Inserts

Usage

- Reinforces fastening locations

- Ensures repeated tightening without wear

2. Aluminum Profiles

(Connected with aluminum profile cnc machining)

Usage

- Structural framing

- Automation rails

- Modular machine parts

3. Precision Bushings

Usage

- Reduces friction in moving assemblies

- Ensures alignment in robotic and automation systems

4. Heat Sinks & Cooling Plates

Usage

- Thermal control in electronics

- Power module cooling

5. Custom Fixture Plates

Usage

- Prototyping test setups

- Alignment platforms

- Device mounting

These accessories expand the versatility and functionality of aluminum prototype assemblies.

CNC Processes Used for Aluminum Prototype Manufacturing

The accuracy of cnc machining aluminum prototypes depends on multiple high-precision machining processes.

Milling

Used for:

- Pocketing

- Surface finishing

- Complex shapes

Turning

Used for:

- Shafts

- Cylindrical components

- Housings requiring concentric accuracy

Drilling & Tapping

Used for:

- Mounting holes

- Threaded inserts

- Precision alignment points

5-Axis CNC Machining

Used for:

- Organic shapes

- Aerospace brackets

- Complex electronic housings

5-axis machining is where aluminum cnc machining supplier capability becomes critical.

Surface Finishing Options for Aluminum CNC Prototypes

Surface finishes enhance appearance, corrosion resistance, and functional durability.

Anodizing

Benefits

- Hard protective layer

- Multiple colors available

- Widely used in electronics

Sandblasting

Benefits

- Uniform matte texture

- Removes machining marks

Powder Coating

Benefits

- Thick protective layer

- Good for mechanical housings

Polishing

Benefits

- Bright, reflective finish

- Suitable for high-end consumer products

Chemical Conversion Coating (Alodine)

Benefits

- Excellent corrosion resistance

- Good for aerospace components

Cost Factors for CNC Machining Aluminum Prototypes

The cnc machining aluminum prototypes cost depends on multiple variables including:

1. Material grade

7075 > 6082 > 6061 in cost.

2. Machining complexity

More toolpaths = more time.

3. Surface finishing

Anodizing and powder coating increase cost.

4. Quantity

Batch orders reduce cost per unit.

5. Tolerance level

Tighter tolerances require slower machining.

Request CNC Machining Aluminum Prototypes — Contact Weldo Machining

Choosing the right machining partner ensures your prototypes achieve structural strength, excellent surface finish, and reliable functionality. As a professional supplier of cnc machining aluminum prototypes, Weldo Machining offers advanced 3-axis and 5-axis machining, precision surface finishing, and fast turnaround for prototypes and small-batch manufacturing.

Contact us today for detailed quotations and more information about cnc machining aluminum prototypes.

FAQ of cnc machining aluminum prototypes

What are the main benefits of CNC machining aluminum prototypes?

They offer excellent accuracy, strength, lightweight performance, and fast production for functional testing and engineering validation.

Which aluminum grades are best for prototypes?

6061 for general parts, 7075 for high strength, 5052 for corrosion resistance, and 6082 for structural applications.

What finishing options are available for aluminum prototypes?

Anodizing, sandblasting, polishing, powder coating, and chemical conversion coatings.