The moment you hear the term “bronze artifacts,” do you immediately picture those ancient vessels with mysterious patterns in museums? If you’re in the know, you’ll recognize that today’s bronze lies within CNC machines, being carved into satellite components, deep-sea valves, and even conductive parts for Tesla motors! Today, let’s explore how this ancient material is being revitalized in modern factories,The following content is about CNC Machining Bronze Guide.

Explanation of CNC machining bronze

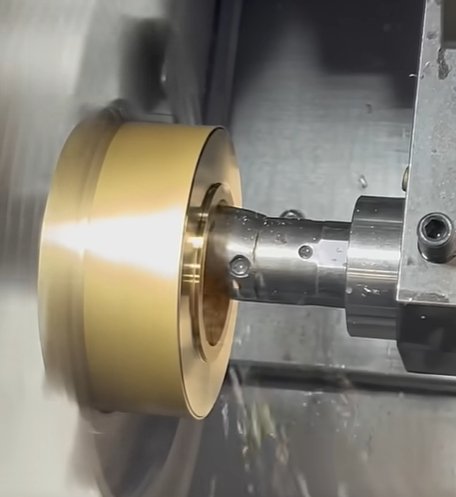

Simply put, it’s computer-controlled machine tools that carve away excess material from bronze blocks like sculpting jade, following precise blueprint designs. Unlike the bronze casting methods used for millennia, CNC can directly carve copper blocks into complex shapes with tolerances as tight as one-twentiethth of a human hair (micron-level precision)! Last year, when we produced satellite bearings for the Aerospace Academy, we used 5-axis machines to carve 0.01mm oil grooves into bronze—enabling them to withstand the -180°C temperatures of space.

CNC machining bronze processing technology

Milling: If you’ve visited a machining workshop, you’ll see it’s like giving bronze a “haircut.” Rotating milling cutters act like barber clippers, shaving flat surfaces and grooves onto bronze. Last year, for valves made for offshore platforms, high-speed milling directly achieved a mirror finish, eliminating the need for subsequent polishing.

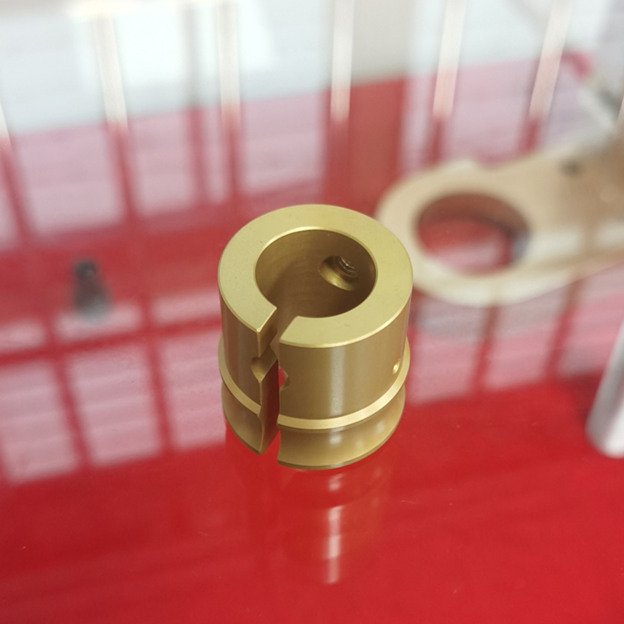

Turning: Bronze’s “Spinning Slimming Session” Primarily targets shaft-like or symmetrical components—such as cylinders or cubes—achieving micron-level precision through rotation and tool feed. For medical prosthetic joint shafts, CNC turning produced 0.5mm fine threads, with patients reporting significantly smoother walking.

Drilling: “Minimally Invasive Surgery” on Bronze. Creating holes in parts is no simple task. Last year, for a nuclear power plant temperature sensor, we drilled 0.3mm blind holes in bronze blocks. Using specialized drills and coolant, we continuously drilled 200 holes without tool wear.

5-Axis Machining: Bronze Sculpture Mastery Adding two rotational axes beyond standard 3-axis CNC allows workpiece adjustments across dual planes. This precision milling tackles complex geometries impossible with traditional methods. For drone propeller hubs with 2mm-thick blades featuring twisted angles, clients exclaimed upon seeing samples: “This isn’t machining—it’s 3D printing!”

Advantages and disadvantages of CNC machining bronze

Advantages:

Excellent Wear Resistance: Lead-containing bronze bearings self-form lubricating films. A textile factory used our bronze gears continuously for three years without replacement.

Strong Corrosion Resistance: No rust even after five years submerged in seawater. Propeller bearings we made for a fishing boat last year were retrieved still gleaming like new.

Easy to machine: With lower hardness than stainless steel, cutting force is reduced by 40%, lowering tool wear costs compared to stainless steel machining.

Excellent electrical and thermal conductivity: Pure copper conducts electricity 1.6 times better than aluminum. Our motor terminals for new energy vehicle manufacturers have twice the overload capacity of aluminum counterparts.

Disadvantages:

High cost: Bronze raw materials cost three times that of aluminum alloys, making it suitable for high-end products.

Sensitive to heat: Continuous machining requires coolant; otherwise, the workpiece will deform.

Difficult to weld: Special solder is required; we typically recommend customers switch to mechanical connections.

Common Application industry for Precision Cnc Bronze Parts

Aerospace:

Satellite attitude control bearings (requiring radiation-resistant aluminum bronze)

Rocket fuel valve bodies (withstanding temperature ranges from -200°C to 300°C)

Automotive & Transportation:

EV motor commutators (pure copper CNC bent tube process)

High-speed rail pantograph sliders (bronze-based composite materials)

Deep-sea Exploration:

Propulsion thrusters for deep-sea probes (must withstand 6000m water pressure)

Ship propeller shaft bushings (nickel-containing bronze for marine biofouling resistance)

Jewelry:

High-end watch clasps (bronze polishing + gold plating)

Custom jewelry (laser-engraved patterns achieve finer detail than handcrafting)

The main types of CNC machining bronze

| Material code | Ingredient characteristics | Suitable Industry | Processing Notes |

| SAE 660 | Copper 83% + Tin 7% + Lead 8% | Bearings and bushings | Use high-pressure coolant when cutting |

| C95400 | Copper 90% + aluminum 7% | Aviation parts | Stress relief treatment is required after processing |

| QSn6.5-0.1 | Copper 93% + Tin 6.5% | Springs, brushes | Suitable for high-speed continuous cutting |

| C67300 | Copper 88% + Manganese 2.5% | Valves, pump bodies | Choose carbide coated cutting tools |

Surface finishes for CNC machining Bronze Parts

Polishing: Bronze Turned to Gold

Mechanical polishing achieves a mirror finish. We polished bronze ornaments for a luxury brand, which were then sold directly as art pieces.

Antiquing: Modern techniques mimic antiquity. Chemical agents create a verdigris oxide layer—the same technique used last year to restore bronze cauldrons at the Forbidden City.

Plating: Armor for bronze. Nickel or chrome plating shields surfaces. A chemical plant reported a ten-year lifespan extension for valves with hard chrome plating.

Engraving: Bronze as Canvas

Laser engraving achieves 0.01mm fine lines. Our logo for an audio brand reveals a 3D effect under light.

Why Dongguan Weldo Excels in Bronze Processing?

Comprehensive Equipment:10 imported 5-axis cnc machines + 50 4-axis cnc machine + 60 3-axis cnc machine capable of machining parts up to 2m diameter. Last year, we machined an 800mm-diameter bearing housing for a wind power plant in three welded sections. The client remarked, “This precision surpasses solid casting.”

Experienced Operators: Our proprietary “Bronze Machining Database” contains over 3,000 processing parameters. An aerospace part that previously required 6 hours of machining was completed in just 3 hours using our optimized solution.

High-level service: Prototype quotes within 72 hours, samples within 48 hours. Last year, we urgently produced ventilator parts for a medical company, completing delivery in just 72 hours from order receipt.

Proven cost control expertise: By optimizing material layout and tool paths, we reduced bronze part costs by 22% for an automotive manufacturer while improving quality by 15%.

Don’t hesitate—contact Weldo for the latest quote

If you face these challenges: Bronze parts consistently miss precision targets Struggling to find reliable suppliers for small-batch orders Traditional processes are costly and time-consuming Contact us immediately with your drawings. Our technical team will reach out within 2 hours to provide: Material selection recommendations Process route planning Cost optimization solutions 48-hour rapid prototyping The Bronze Age never ended—it simply donned new CNC attire, continuing to write industrial legends in Dongguan workshops. Choose Weldo—empower your products with five millennia of metalworking wisdom!