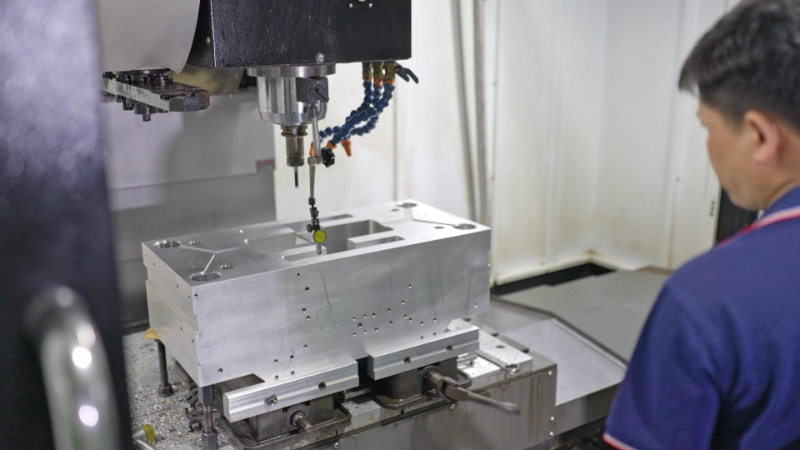

When evaluating a manufacturing partner, real cnc machining capabilities determine whether your parts are delivered accurately, efficiently, and at a sustainable cost. At Weldo Machining, our cnc machining capabilities are built around flexibility, precision, and practical manufacturing experience—supporting everything from simple components to complex multi-axis parts.

CNC Machining Capabilities Built for Real Manufacturing Needs

At Weldo Machining, cnc capabilities are not limited to advanced equipment alone. They represent a complete manufacturing system that integrates machine selection, process planning, material knowledge, and quality control. This approach allows us to support customers across different industries while maintaining consistent results.

Our cnc machining capabilities are designed to serve both small and large components, prototypes and production parts, and simple geometries as well as high-precision assemblies. By combining advanced CNC technology with conventional machining methods, we help customers optimize cost without compromising performance.

Multi-Axis CNC Machining Capabilities (3-Axis, 4-Axis, and 5-Axis)

3-Axis CNC Machining Capabilities for Efficient Production

3-axis machining remains the backbone of many industrial parts. Weldo Machining’s cnc machining capabilities in 3-axis CNC are ideal for brackets, plates, housings, and general mechanical components. These processes offer fast cycle times and excellent cost efficiency for straightforward geometries.

For many standard parts, our 3-axis cnc capabilities significantly reduce machining cost while maintaining stable dimensional accuracy.

4-Axis CNC Machining Capabilities for Improved Feature Access

4-axis machining expands our cnc machining capabilities by enabling indexed machining on multiple faces in fewer setups. This improves positional accuracy and reduces handling time, making it ideal for components with side features, slots, or angled holes.

By using 4-axis CNC machining, Weldo Machining enhances consistency and reduces lead time for medium-complexity parts.

5-Axis CNC Machining Capabilities for Complex Geometry

Our advanced cnc capabilities include 5-axis machining using HAAS and Hurco 5-axis machining centers. These machines allow simultaneous multi-axis movement, enabling the production of complex contours, deep cavities, and precision surfaces in a single setup.

5-axis cnc machining capabilities are essential for aerospace-style geometries, high-precision tooling, medical components, and parts with strict positional requirements.

HAAS and Hurco 5-Axis Machining Centers

Weldo Machining operates HAAS and Hurco five-axis machining centers, forming a key part of our high-end cnc machining capabilities. These platforms offer excellent rigidity, repeatability, and programming flexibility.

With HAAS and Hurco systems, our cnc capabilities support:

- Reduced setups and improved accuracy

- Stable machining of complex surfaces

- Efficient machining of both small and large parts

- Faster transition from prototype to production

This combination allows Weldo Machining to deliver consistent results even for demanding applications.

Large and Small Part CNC Machining Capabilities

One of the advantages of Weldo Machining’s cnc capabilities is the ability to handle both large and small components. From compact precision parts to oversized mechanical structures, our equipment range and process planning allow us to adapt machining strategies to part size and complexity.

This flexibility ensures that customers do not need to source different suppliers for different component scales.

EDM Machining Capabilities (Wire EDM Solutions)

Fast Wire EDM (High-Speed Wire Cutting)

Weldo Machining’s cnc machining capabilities include fast wire EDM for efficient cutting of conductive materials. Fast wire EDM is suitable for cost-sensitive parts and rough profiling where speed and efficiency are priorities.

Medium-Speed Wire EDM for Precision Profiles

Medium-speed wire EDM expands our cnc capabilities by offering higher accuracy and improved surface finish compared to fast wire EDM. This process is widely used for precision molds, inserts, and components with intricate internal shapes.

EDM machining allows Weldo Machining to handle features that are difficult or impossible to produce using conventional CNC milling alone.

CNC Grinding Capabilities for High-Precision Surfaces

CNC grinding is an important extension of our cnc machining capabilities, especially for parts requiring tight tolerances, smooth surface finishes, or precise dimensional control.

Our CNC grinding capabilities support:

- Flat surface grinding

- Dimensional correction after heat treatment

- Improved surface roughness for functional interfaces

By integrating CNC grinding into the process chain, Weldo Machining ensures accuracy where milling or turning alone may not be sufficient.

CNC Turning and Milling-Turning Combination Capabilities

Weldo Machining provides cnc machining capabilities that include CNC turning and milling-turning combination processes. These capabilities are ideal for shafts, bushings, cylindrical housings, and parts requiring both rotational and prismatic features.

Milling-Turning for Process Integration

Milling-turning combination machining reduces setups, improves concentricity, and shortens production cycles. As part of our cnc machining capabilities, this approach enhances quality while lowering overall manufacturing cost.

Conventional Turning and Milling for Cost Optimization

In addition to advanced CNC systems, Weldo Machining maintains conventional turning and milling equipment. These traditional processes are a strategic part of our cnc machining capabilities, especially for simple parts, secondary operations, or large-volume basic components.

By selecting conventional machining where appropriate, we:

- Reduce unnecessary CNC machine time

- Lower part cost for standard components

- Increase overall production efficiency

This balanced approach allows Weldo Machining to deliver competitive pricing without sacrificing quality.

How Our CNC Machining Capabilities Reduce Cost and Improve Efficiency

Effective cnc capabilities are not about using the most complex machine for every job. At Weldo Machining, we focus on process optimization.

Key advantages include:

- Matching machine type to part complexity

- Combining CNC and conventional machining strategically

- Reducing setups through multi-axis machining

- Improving throughput with efficient programming

These practices allow customers to achieve high-quality parts while controlling manufacturing budgets.

Quality Control Within Our CNC Machining Capabilities

Quality assurance is integral to Weldo Machining’s cnc capabilities. Inspection and verification are built into every stage of production to ensure consistency and compliance with drawing requirements.

Our quality-focused cnc machining capabilities include:

- In-process dimensional checks

- Final inspection of critical features

- Controlled documentation for precision components

This ensures reliable delivery, whether for prototypes or repeat production.

Industries Supported by Weldo Machining Capabilities

Weldo Machining’s cnc machining capabilities support a wide range of industries, including:

- Industrial machinery and automation

- Tooling and fixtures

- Automotive and transportation components

- Energy and equipment manufacturing

- General mechanical and structural parts

Our flexible capability structure allows us to adapt quickly to different technical requirements.

Conclusion: CNC Machining Capabilities That Deliver Real Value

Weldo Machining’s cnc capabilities combine 3-axis, 4-axis, and 5-axis CNC machining, HAAS and Hurco 5-axis centers, EDM wire cutting, CNC grinding, milling-turning combinations, and conventional machining methods. This integrated capability allows us to machine both large and small parts efficiently while significantly reducing cost and improving production efficiency for standard components. If you are looking for a reliable manufacturing partner with comprehensive cnc machining capabilities, contact Weldo Machining today to discuss your project requirements and receive technical support and a competitive quotation.