When strength, durability, and affordability are critical, carbon steel stands out as one of the most trusted metals in industrial manufacturing. However, achieving precision and consistency with this tough material requires partnering with the right CNC machining carbon steel manufacturer.

Whether you’re sourcing one-off prototypes or bulk production components, this guide walks you through what to look for in a trusted CNC machining company, supplier, or factory—from technical capabilities to quality assurance, pricing models, and more.

Why Carbon Steel Requires a Specialized CNC Machining Company

While carbon steel is widely available and cost-effective, its hardness, tensile strength, and chip-forming characteristics make it more challenging to machine than softer materials like aluminum or brass.

A reliable CNC machining carbon steel factory understands:

- The differences between grades like 1018, 1045, and 4140

- Optimal tooling, feeds, and speeds for high-efficiency cutting

- Post-machining treatments such as heat treating, passivation, or coating

- How to manage tight tolerances for custom components

Generic machine shops may struggle with tool wear and quality control. That’s why working with a specialized carbon steel manufacturer ensures both performance and consistency.

Understanding Carbon Steel Grades and Their Machining Behavior

Not all carbon steels behave the same under CNC processes. Here’s a breakdown of popular grades:

| Steel Grade | Standard / Region | Machinability | Heat Treatable | Typical Applications |

|---|---|---|---|---|

| 1018 | AISI / SAE (US) | Excellent | No (as-delivered) | Pins, shafts, bushings, brackets |

| 1020 | AISI / SAE (US) | Very Good | Yes (mild) | Bolts, general parts, automotive components |

| 1045 | AISI / SAE (US) | Moderate | Yes | Gears, flywheels, couplings, hydraulic parts |

| 1215 | AISI / SAE (US) | Outstanding (free-machining) | No | High-speed CNC parts, bushings, turned components |

| 1144 (Stressproof®) | Proprietary / AISI | Very Good | Limited | Precision shafts, press-fit parts, tool holders |

| 4140 | AISI / SAE (US) | Moderate | Yes (excellent response) | Tools, dies, structural high-load components |

| A36 | ASTM (US) | Fair | Yes (limited) | Structural plates, frames, welded brackets |

| EN8 / EN9 | BS / EN (UK) | Similar to 1045 | Yes | Industrial components, hubs, flanges |

| Q235 / Q345 | GB (China) | Moderate | Limited | OEM structural parts, enclosures, brackets |

A seasoned carbon steel machining supplier will help you choose the right grade for cost efficiency and performance, considering both material behavior and end-use.

What to Expect from a Reliable CNC machining carbon steel manufacturer

When evaluating potential manufacturers, look beyond just the machinery. A high-quality CNC machining carbon steel company should provide:

✅ Full-Service Machining Capabilities

- 3-axis to 5-axis milling & CNC turning

- Wire EDM or grinding for ultra-precise features

- Threading, drilling, slotting, and grooving

- Heat treatment and surface coating coordination

Whether you’re ordering small custom parts or large metal components, having these services under one roof reduces delays and increases quality control.

✅ Tolerance and Inspection Capabilities

Carbon steel parts often operate under mechanical load or high stress. That’s why factories must support:

- ±0.01 mm or better tolerances

- Surface finishes down to Ra 0.8 µm

- CMM inspection, 100% visual check, and dimensional reports

- Traceable QA processes (ISO 9001, AS9100)

How to Evaluate a Carbon Steel Machining Supplier or Factory

Every factory will promise quality—but not all deliver. Use the following checklist when evaluating a carbon steel CNC manufacturer:

| Criterion | What to Look For |

|---|---|

| Experience | 5+ years in carbon steel projects |

| Certifications | ISO 9001, material traceability |

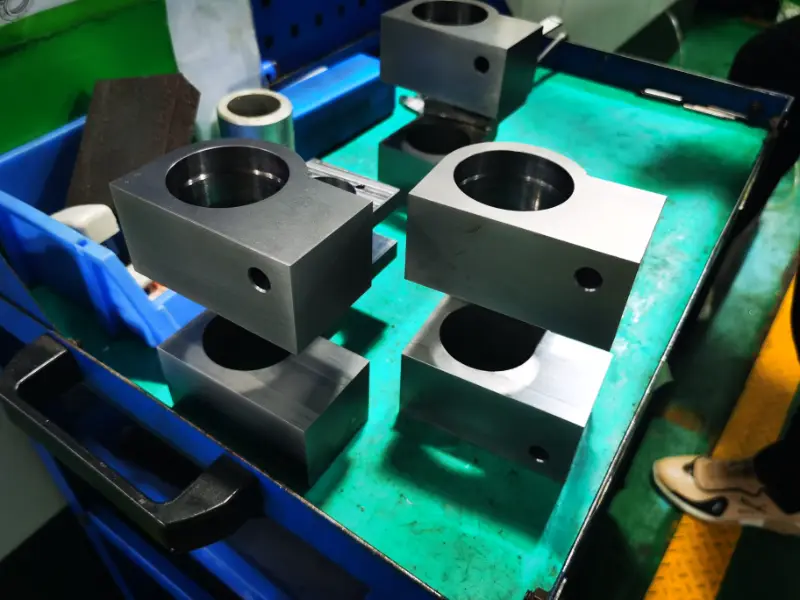

| Sample portfolio | Photos or case studies of carbon steel parts |

| Material sourcing | Verified mills for 1018, 1045, 4140 grades |

| Finishing options | Black oxide, zinc plating, phosphate coating |

| Communication | Fast DFM feedback and quoting turnaround |

Pro tip: Ask whether the company supports prototype-to-production scaling, which allows faster transitions when your project grows.

Cost Considerations: How Pricing Works with Carbon Steel Manufacturers

Cost transparency is critical. A professional CNC machining carbon steel supplier will typically break down costs as follows:

1. Material Cost

Depends on the carbon content, grade, and size.

e.g., 1018 is ~$0.80–1.10/kg, while 4140 may reach $2.00/kg.

2. Machining Time

Harder grades like 1045 or 4140 take longer to cut, raising machine time and tooling costs.

3. Tooling & Wear

High-speed steel and carbide tools wear faster on carbon steel, leading to more frequent replacements and increased unit cost.

4. Surface Finishing

Optional but common. Examples include:

- Black oxide ($2–$6/part)

- Powder coating or painting

- Oil coating for corrosion resistance

5. Batch Volume

The more parts you produce, the lower the cost per unit. Setup time amortizes over large batches.

| Quantity | Cost per Part (Estimate) |

|---|---|

| 1–10 pcs | $80–$160 |

| 50–100 pcs | $35–$70 |

| 500+ pcs | $15–$30 |

Local vs. Overseas Carbon Steel CNC Manufacturers

| Feature | Local (US/EU) | Overseas (e.g., China – Weldo) |

|---|---|---|

| Price | Higher labor & material costs | Competitive bulk pricing |

| Lead Time | Shorter for low volume | Slightly longer (but scalable) |

| Certifications | Easy verification | ISO/ROHS usually provided |

| Volume Capacity | May be limited | High-capacity full-line production |

| Communication | Real-time, same time zone | Requires clear documentation |

For large or recurring projects, trusted overseas manufacturers like Weldo Machining deliver both cost-efficiency and industrial-level quality.

Real Project Example: Carbon Steel Pulley from Weldo

Client: Industrial automation company

Part: 1045 carbon steel pulley

Processes: CNC turning + milling, keyway cutting, black oxide

Tolerances: ±0.02 mm

Volume: 300 pcs

Lead Time: 14 working days

Result:

- 98.5% yield rate

- On-time delivery

- Full dimensional inspection provided

- Repeated order confirmed for 600 pcs next batch

This project demonstrates how a seasoned CNC machining carbon steel company manages technical challenges, meets deadlines, and ensures repeatable quality.

Why Choose Weldo as Your CNC Carbon Steel Manufacturer

At Weldo Machining, we offer:

- Full-service CNC machining of carbon steel grades (1018, 1045, 4140)

- Tight-tolerance production with inspection reports

- Rapid prototyping + mass production scaling

- Surface finishing, packaging, and global shipping

- Transparent quoting and fast DFM feedback

Contact us today to get a tailored quote or submit your technical drawings for free manufacturability analysis.