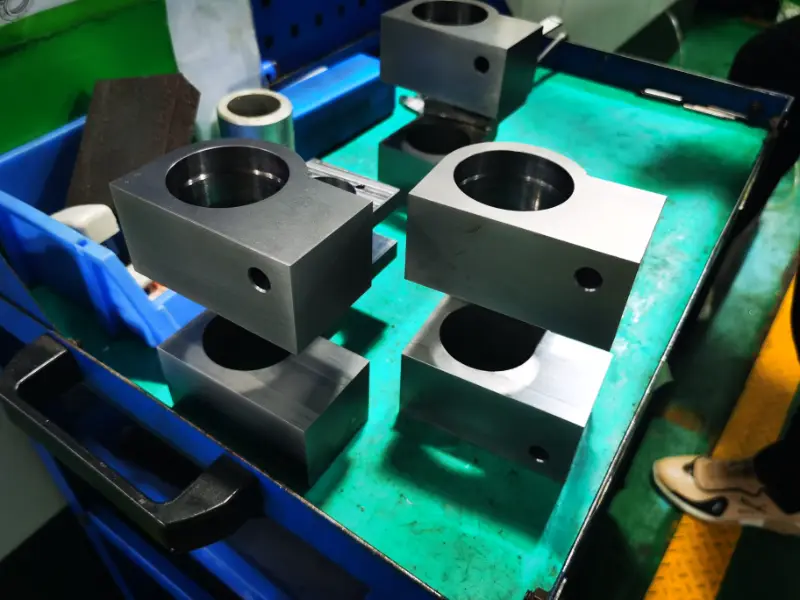

Bridging the gap between design and production often begins with one critical step: the prototype. When that prototype demands strength, durability, and machinability, CNC machining carbon steel prototype services offer unmatched precision and repeatability.

From automotive trials to mechanical testing, carbon steel prototypes allow engineers to validate designs using real-world materials and functional performance—before committing to large-scale production.

Why Carbon Steel Is Ideal for Prototyping Functional Metal Parts

When you need a prototype that functions under real mechanical loads, plastic or 3D-printed parts won’t suffice. Carbon steel provides:

- Excellent strength and impact resistance

- Wide availability in grades like 1018, 1045, 4140

- Compatibility with heat treatments

- Reliable prototype machining behavior

Whether you’re developing a trial part, gear component, fixture, or bracket, carbon steel ensures the prototype behaves similarly to the final product—essential for high-stress applications.

Choosing the Right Carbon Steel Grade for Your Prototype

Not all carbon steels are created equal. The grade you select for your CNC machining carbon steel prototype depends on the performance characteristics you want to test.

| Grade | Strength | Machinability | Use Case |

|---|---|---|---|

| 1018 | Low | Excellent | General-purpose parts, low-stress components |

| 1045 | Medium | Moderate | Shafts, couplings, moderately loaded parts |

| 4140 | High | Lower | Structural, aerospace, and tooling prototypes |

| 1215 | Low | Outstanding | Non-structural, high-precision samples |

If you’re unsure which steel suits your prototype best, a qualified carbon steel prototype machining company like Weldo can help recommend the most suitable grade for your functional test goals.

How Prototype Machining Works for Carbon Steel Parts

The CNC machining process for carbon steel prototypes typically includes:

- DFM Review (Design for Manufacturability)

CAD files are analyzed to verify tolerance feasibility and steel grade compatibility. - Material Selection & Preparation

Raw bars or plates of carbon steel (e.g., 1018, 1045) are sourced and cut to blank sizes. - CNC Turning/Milling/Drilling

Machining is performed using optimized feeds and speeds, considering chip toughness and tool wear for each grade. - Optional Heat Treatment / Finishing

Some trial parts may require hardening, surface coatings, or protective finishes. - Inspection & Delivery

Dimensional reports or material certificates may be provided upon request—especially for steel testing applications.

The goal is to create a functional sample that replicates the intended final part both structurally and geometrically.

Prototyping vs. Low Volume Production in Carbon Steel

Clients often confuse prototyping with short-run production. Here’s how they differ:

CNC Machining Carbon Steel Prototype

- Usually 1–5 parts

- Focus on design validation

- Higher cost per part

- Quick turnaround (2–7 days)

Low Volume Production

- 10–200+ units

- Focus on end-use performance

- Optimized fixture setups

- Cost benefits from setup amortization

At Weldo Machining, we help clients scale from a sample to a batch, offering consistency across both stages.

Use Cases: Who Needs CNC Carbon Steel Prototypes?

Industries that rely heavily on CNC-machined carbon steel trial parts include:

- Automotive: Suspension arms, mounting brackets, and housings

- Aerospace: High-strength fixtures and support brackets

- Oil & Gas: Testing of couplings, valves, and threaded components

- Manufacturing Equipment: Custom tooling, dies, and structural jigs

- Defense and Robotics: Functional prototypes for high-impact environments

In each case, functional prototype machining must mimic the mechanical properties of production parts—hence the need for carbon steel over aluminum or polymer.

Cost Factors in CNC Machining Carbon Steel Prototypes

When requesting a quote for a carbon steel prototype, consider the following cost drivers:

1. Material Grade and Size

Some steel grades like 4140 are more expensive and harder to cut, raising both material and machining costs.

2. Part Complexity

Deep pockets, thin walls, or tight tolerances will increase machine time.

3. Finishing Requirements

If your prototype sample needs black oxide coating, heat treatment, or polishing, these will add to the cost.

4. Quantity

Although prototypes are often one-off, ordering 2–5 parts may reduce per-unit cost through shared setup.

Typical carbon steel prototypes can range from $80–$200 per part, depending on complexity.

Global Sourcing: Domestic vs. Overseas Prototype Suppliers

| Aspect | Local (e.g., U.S./EU) | Overseas (e.g., China – Weldo) |

|---|---|---|

| Cost per prototype | Higher ($120–$250) | Lower ($60–$120) |

| Lead time | 3–5 days | 5–8 days (air express) |

| Communication | Same timezone | Requires clear documentation |

| QA Process | Transparent | Requires verified partner |

A trusted CNC machining carbon steel prototype supplier like Weldo offers global quality, fast lead times, and technical support—even for urgent prototype jobs.

Weldo Machining: Your Partner in Carbon Steel Prototypes

Whether you’re preparing a part for fatigue testing or client validation, Weldo Machining delivers high-quality CNC carbon steel prototypes with:

- Tight tolerance control (±0.01 mm)

- ISO-compliant material traceability

- Multiple carbon steel grades in stock

- Support for prototype-to-production scaling

- Optional finishing, heat treatment, and inspection reports

Contact us now for a free prototype review, instant quote, or to submit your drawings for DFM optimization.