Finding a dependable cnc machining flange manufacturer has become essential for engineering teams working on hydraulic systems, industrial equipment, automotive power units, aerospace assemblies, and fluid-control solutions. Flanges must maintain perfect alignment, flatness, and sealing capability under high mechanical load, making precision CNC machining the most reliable method for producing functional prototypes and small-batch flange components.

Why Flange Manufacturing Requires More Than Standard CNC Skills

While many shops offer turning and milling, flange manufacturing demands a higher level of precision. A qualified cnc machining flange manufacturer must consistently achieve:

- Stable concentricity between bore and bolt-circle

- Flat and smooth sealing faces

- Accurate bolt-hole spacing

- High structural strength for pressure systems

- Precise tolerances for mating components

These requirements exceed typical machining tasks, making specialized knowledge essential.

Industry Environments That Rely on High-Accuracy Flange Machining

To understand why engineers look for a dedicated flange cnc machining service, consider the demanding environments flanges operate in.

Automotive High-Heat Interfaces

Turbo housings, exhaust systems, fluid routing modules, and pump connections rely on CNC-machined flanges to withstand continuous heat cycles, vibration, and mechanical stress.

Industrial Pumps, Compressors & Valves

Sealing surfaces must maintain flatness even under fluctuating pressure. High-precision precision flange cnc parts undergo torque, fatigue, and leakage tests before approval.

Aerospace Ducting and Air Transport Systems

Lightweight aircraft components use aluminum or titanium flange structures requiring perfect concentricity, vibration resistance, and minimal mass without compromising strength.

Oil, Gas & Chemical Processing

Corrosion-resistant stainless steel flanges are prototyped and tested to ensure they remain leak-free in aggressive environments.

What Defines a True CNC Machining Flange Manufacturer?

Unlike general machine shops, a specialized cnc machining flange manufacturer integrates machining capability with engineering understanding. Their production system typically includes:

A. Integrated Turning and Milling Cells

Flanges require both round-feature turning and bolt-pattern milling. Shops with synchronized turning–milling workflows can maintain tighter dimensional stability.

B. Metrology-Driven Production

Inspection equipment provides:

- Bore diameter verification

- Bolt-hole positional accuracy

- Flatness and surface roughness reports

- CMM inspection for critical geometry

This ensures every flange behaves like a production-grade part.

C. Multi-Material Expertise

Different industries require different materials:

- Stainless steel (304, 316, 2205): corrosion protection

- Carbon steel (A105, 1045): high mechanical strength

- Aluminum (6061, 7075): lightweight components

- Brass & bronze: exceptional sealing performance

- Engineering plastics (POM, PEEK): specialty insulation

A strong supplier understands how each behaves under machining loads.

How a Flange Is Manufactured — A Technical Yet Practical View

A competent custom flange machining company follows a deep engineering workflow from start to finish.

Stage 1 — Model Review & Fitment Analysis

Engineers evaluate:

- Bolt-hole patterns

- Mating components

- Expected pressure levels

- Sealing surface function

- Tolerance zones

This prevents downstream failures.

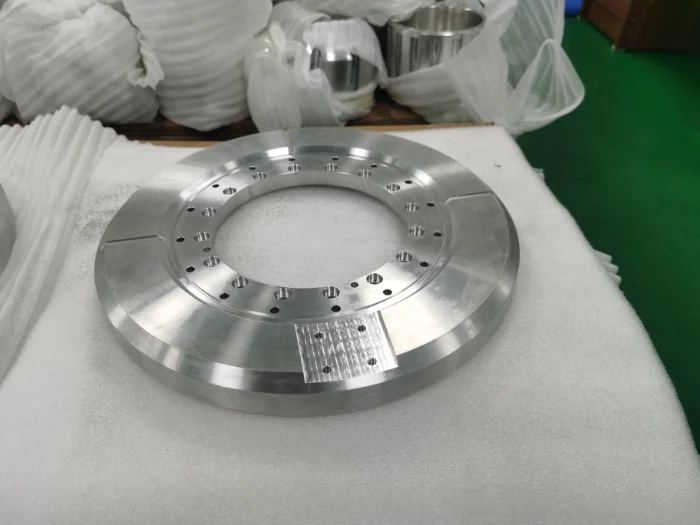

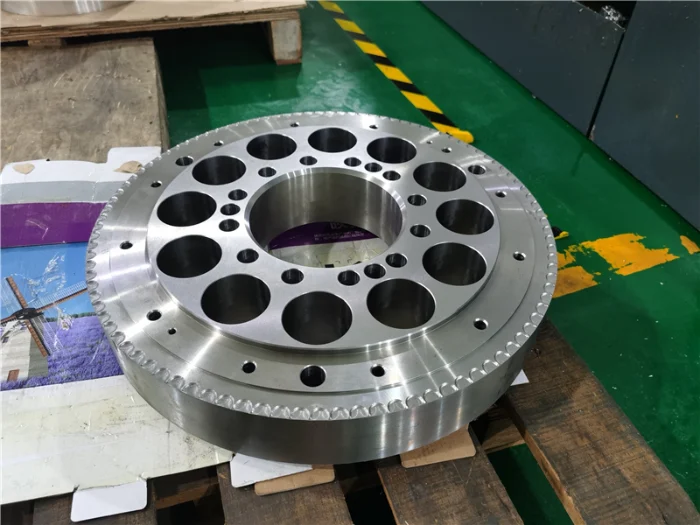

Stage 2 — Precision Turning

The outer diameter, inner bore, and face surfaces are shaped using controlled turning cycles. Cutting parameters are optimized to prevent warping or chatter.

Stage 3 — Controlled Milling Cycles

Milling is used for:

- Bolt-hole circle drilling

- Keyways

- Custom features

- Grooves or O-ring seats

Accurate index positioning ensures consistent bolt-hole symmetry.

Stage 4 — Deburring & Functional Surface Processing

Finishing operations include:

- Chamfering

- Polishing the sealing face

- Controlled deburring around bolt holes

- Optional surface grinding

This stage determines final performance in pressure tests.

Stage 5 — Dimensional Inspection & Validation

Flange quality is verified through:

- Flatness measurements

- Concentricity checks

- Positional accuracy

- Pressure-fit simulation

Only then does the part qualify as a functional prototype.

Machining Challenges Unique to Flange Production

1. Maintaining flat sealing surfaces

Solved by fine-feed finishing + surface grinding.

2. Controlling bolt-hole alignment

Achieved through in-process probing and indexed drilling.

3. Preventing warping during heavy cuts

Mitigated using multiple roughing passes and controlled temperatures.

4. Ensuring concentricity between OD and bore

High-stability turning + proper fixturing.

A capable cnc machining flange manufacturer must manage all these factors simultaneously.

Cost Drivers in Flange CNC Machining

The pricing of precision flange cnc parts generally depends on:

- Material hardness and machinability

- Diameter & thickness

- Bolt-hole complexity

- Required tolerances

- Surface finishing

- Quantity (prototype vs. small batch)

Understanding these cost drivers helps engineers plan realistic budgets.

Designing Better Flanges for CNC Machining

To ensure efficient production and lower cost:

- Use standardized bolt patterns when possible

- Keep wall thickness consistent

- Avoid extreme groove depths

- Add fillets to reduce stress concentration

- Apply GD&T selectively

- Specify fine surface finish only where necessary

This ensures smoother cooperation with any custom flange machining company.

How to Choose a Reliable CNC Machining Flange Manufacturer

Selecting the right supplier is critical to a successful project. A dependable cnc machining flange manufacturer should offer:

1. Proven precision

Ability to control sealing flatness, bolt-hole accuracy, and concentricity.

2. Complete machining capability

Turning + milling equipment capable of handling complex flange geometries.

3. Strong quality control system

CMM measurement and full inspection documentation.

4. Material & engineering support

Experience with metals, plastics, and application-specific recommendations.

5. Transparent communication

Clear pricing, realistic delivery times, and responsive technical feedback.

A supplier meeting these criteria ensures dependable performance in every prototype or small-batch production.