CNC machining for beginners is often the first step into modern manufacturing. This guide explains what CNC machining is, why it matters, how costs and quality are controlled, and what tools, materials, standards, and management practices are involved—using clear structure and practical examples.

What Is CNC Machining?

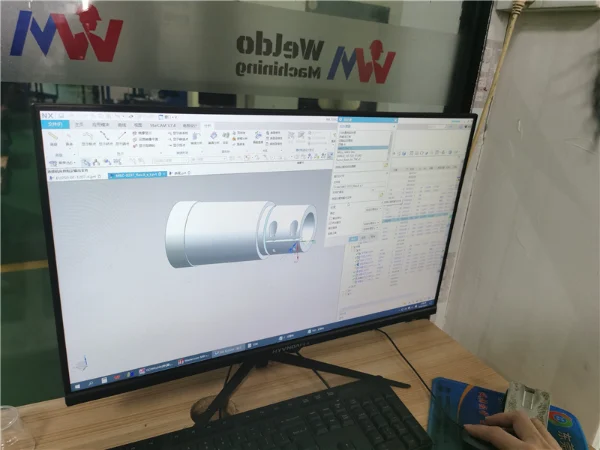

CNC machining for beginners starts with understanding the definition. CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls machine tools to remove material from a workpiece. Using CAD/CAM files, machines execute precise movements to achieve tight tolerances and consistent surface finish across parts.

Why CNC Machining Is Important

For CNC machining for beginners, its importance lies in:

- High repeatability and dimensional accuracy

- Scalability from prototypes to production

- Compatibility with metals and engineering plastics

- Reduced human error compared with manual machining

Industries such as aerospace, automotive, and medical rely on CNC milling and CNC turning to meet strict specifications.

Advantages and Disadvantages of CNC Machining

Advantages

- High precision and repeatability

- Capability to machine complex geometries

- Automated and efficient production processes

Disadvantages

- Higher initial equipment investment

- Skilled programming and setup required

- Less economical for extremely small quantities

Understanding these trade-offs is essential for CNC machining for beginners when selecting manufacturing methods.

How CNC Machining Costs Are Calculated

In CNC machining for beginners, cost calculation typically includes:

- Machine hourly rate

- Raw material cost and waste

- Setup time and cycle time

- Tool wear and inspection requirements

Accurate cost estimation helps balance quality, lead time, and budget.

How to Control and Reduce CNC Machining Costs

To improve cost efficiency in CNC machining for beginners:

- Simplify part geometry where possible

- Avoid unnecessarily tight tolerances

- Optimize tool paths in CAD/CAM software

- Combine parts or batch production to reduce setups

Early design-for-manufacturing (DFM) evaluation plays a key role in cost control.

Ensuring CNC Machining Quality and Standard Requirements

Quality assurance in CNC machining for beginners involves:

- First Article Inspection (FAI)

- In-process dimensional checks

- Final inspection against drawings and specifications

Many CNC machining factories operate under ISO 9001 or similar quality systems to ensure consistency and traceability.

Common CNC Machining Materials and Their Applications

For CNC machining for beginners, understanding commonly used materials and their applications is essential for selecting the right manufacturing solution. Different materials directly influence machining strategy, cost, lead time, and final performance.

Common CNC Machining Materials

- Aluminum alloys (6061, 7075)

Lightweight, corrosion-resistant, and easy to machine. Commonly used for structural parts, enclosures, brackets, and heat sinks. - Carbon steel and alloy steel

High strength and durability, suitable for shafts, gears, flanges, and load-bearing components. - Stainless steel (304, 316)

Excellent corrosion resistance, widely used in medical devices, food-grade components, and industrial equipment. - Brass and copper

Good electrical and thermal conductivity, often applied in connectors, bushings, valves, and electrical parts. - Engineering plastics (POM, ABS, Nylon, PEEK)

Lightweight and wear-resistant, ideal for housings, functional prototypes, and insulating components.

Material choice is a critical decision point in CNC machining for beginners, directly affecting manufacturability and cost efficiency.

Typical CNC Machined Parts and Application Fields

CNC machining supports a wide range of industries, producing components such as:

- Mechanical parts: brackets, housings, shafts, flanges

- Automotive components: fixtures, engine parts, custom fittings

- Aerospace parts: precision structural components and mounts

- Medical devices: surgical tools, equipment housings

- Electronics and industrial equipment: enclosures, heat sinks, connectors

Material Selection Guide for CNC Machining Beginners

For CNC machining for beginners, material selection should never be based on price alone. The correct material must balance performance, machinability, environmental resistance, and total production cost.

Key Factors to Consider When Selecting CNC Machining Materials

- Mechanical Properties and Functional Requirements

Match strength, hardness, and wear resistance to actual working conditions rather than over-engineering the part. - Machinability and Tool Wear

Materials such as aluminum and brass reduce cycle time and tool wear, while stainless steel requires optimized cutting parameters. - Tolerance and Surface Finish Requirements

Stable materials like aluminum and POM are better suited for tight tolerances and fine surface finishes. - Environmental and Corrosion Resistance

Stainless steel and treated aluminum are preferred for corrosive or outdoor environments. - Material Availability and Lead Time

Standard grades help avoid delays and supply risks. - Cost Optimization Across the Part Lifecycle

A higher-grade material may reduce machining time, scrap rate, or secondary processes.

Avoid common mistakes such as selecting exotic materials without justification or ignoring machinability during design. Following this Material Selection Guide for CNC Machining Beginners helps ensure reliable quality and predictable production outcomes.

Common CNC Tools and Equipment

Typical CNC machining setups include machine tools, workholding devices, and inspection equipment. For CNC machining for beginners, understanding each category helps ensure stable production and consistent quality.

- CNC milling machines

Used for flat surfaces, slots, and complex 3D features. Suitable for prismatic parts and multi-axis machining. - CNC lathes

Designed for rotational parts such as shafts and bushings, providing good concentricity and surface finish. - Workholding fixtures

Including vises, clamps, and custom fixtures. Proper fixturing ensures stability and dimensional accuracy. - Measuring and inspection tools

Calipers, micrometers, and CMMs support in-process and final inspection to verify drawing requirements.

A balanced combination of equipment is essential for reliable CNC machining operations.

CNC Milling Cutter Types and Their Functions

In CNC machining for beginners, common milling cutters include:

- Flat end mills for slotting and profiling

- Ball nose end mills for 3D contours

- Corner radius end mills for stronger cutting edges and finishing

Correct cutter selection improves efficiency and surface finish.

Common CNC Machining Problems, Risks, and Solutions

- Tool breakage: adjust feeds, speeds, and cutter selection

- Dimensional deviation: verify fixtures and offsets

- Poor surface finish: optimize tool paths and cutting parameters

Early detection prevents scrap and rework.

CNC Machining Factory Management Practices

Well-managed CNC shops implement:

- Preventive maintenance programs

- Tool life tracking systems

- Standard operating procedures (SOPs)

- Operator training and documentation control

Ensuring CNC Machining Meets Customer Drawing Requirements

To meet drawing requirements in CNC machining for beginners, factories rely on:

- Drawing and revision control

- CAD/CAM simulation before machining

- CMM inspection for GD&T verification

Clear communication between engineering, production, and inspection teams is essential.

Measurement Instruments and Usage Considerations

Accurate measurement is critical in CNC machining for beginners to confirm part conformity.

- Calipers

Used for quick checks of basic dimensions during machining. - Micrometers

Provide higher accuracy for critical dimensions and tight tolerances. - CMMs

Applied for complex geometry and GD&T inspection.

Regular calibration, proper handling, and standardized measurement procedures ensure reliable inspection results.

Final Thoughts

We hope this article will truly help you succeed in the CNC machining field, enabling you to continuously achieve higher precision machining requirements. If you are looking for professional support, reliable production, or competitive pricing, please contact Weldo Machining. We will provide you with detailed technical consultation and customized CNC machining quotes.