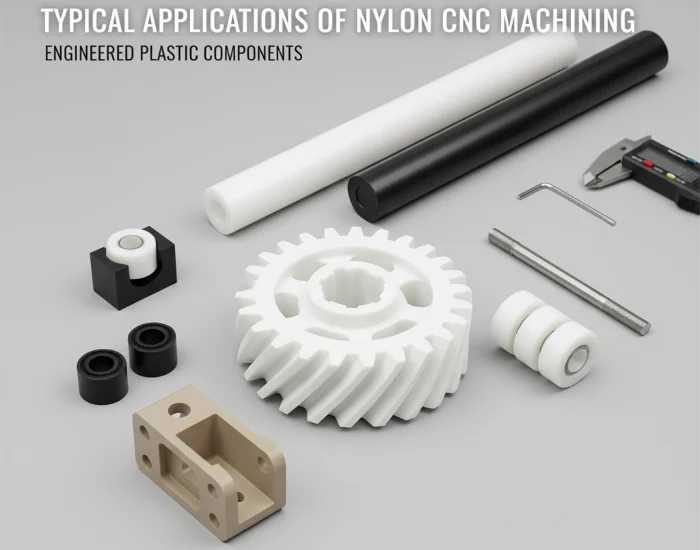

Understanding cnc machining nylon cost is essential for companies looking to produce high-quality nylon components while maintaining tight budget control. Nylon (PA) is one of the most cost-effective engineering plastics for CNC machining, but final pricing varies based on material grade, part design, machining strategy, and quality requirements. This page explains how cnc nylon cost is calculated, how manufacturers reduce cost without compromising precision, and what machining considerations matter most.

What Determines CNC Machining Nylon Cost

There is no fixed price for CNC-machined nylon parts. Cnc machining nylon cost is influenced by several interconnected factors that affect machining time, material utilization, and quality stability.

Key cost drivers include:

- Nylon material grade (PA6, PA66, modified nylon)

- Part size and geometry complexity

- Tolerance and surface finish requirements

- CNC machining time

- Order quantity

Understanding these variables helps buyers evaluate quotations accurately.

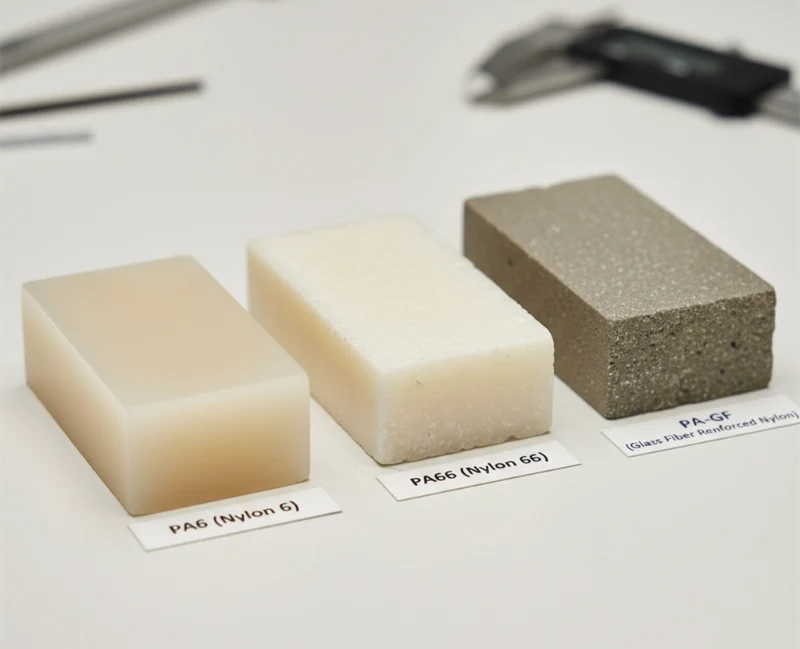

CNC Machining Nylon Cost by Material Grade

Different nylon materials result in different cnc nylon cost outcomes.

PA6 Nylon CNC Machining Cost

PA6 offers good toughness and machinability at a lower material price.

- Lower raw material cost

- Faster machining speed

- Lower overall cnc nylon cost

PA6 is ideal for cost-sensitive applications.

PA66 Nylon CNC Machining Cost

PA66 provides higher stiffness and wear resistance but at a higher cost.

- Higher material price than PA6

- Slightly longer machining time

- Higher but more stable cnc machining nylon cost

PA66 is preferred when precision and durability outweigh cost sensitivity.

Glass-Filled and Modified Nylon Cost Impact

Reinforced or modified nylons increase strength but also machining complexity.

- Higher tool wear

- Slower cutting speeds

- Increased cnc machining nylon cost

These materials should be selected only when required by load conditions.

Typical CNC Machining Nylon Cost Range (USD)

For reference purposes only, typical cnc nylon cost ranges are:

- Simple nylon CNC parts: USD 25–80 / part

- Medium complexity nylon parts: USD 40–120 / part

- High-precision nylon CNC components: USD 80–180 / part

Higher volumes significantly reduce unit cnc machining nylon cost.

How to Reduce CNC Machining Nylon Cost Without Losing Quality

Lowering cnc machining nylon cost does not mean sacrificing performance or accuracy.

Effective cost-reduction strategies include:

- Selecting the correct nylon grade instead of over-specifying

- Optimizing part geometry for CNC machining

- Avoiding unnecessarily tight tolerances

- Choosing functional surface finishes instead of cosmetic ones

- Increasing batch size where possible

An experienced supplier applies these methods to control cost while maintaining quality.

Design Optimization to Control CNC Machining Nylon Cost

Design has a direct impact on cnc machining nylon cost.

Best practices include:

- Avoiding thin walls that cause deformation

- Using generous internal radii

- Designing uniform wall thickness

- Specifying realistic tolerances

Early DFM review significantly reduces machining time and rework.

Machining Considerations Affecting CNC Machining Nylon Cost

Nylon behaves differently from metal during CNC machining.

Common challenges include:

- Material deformation due to heat

- Moisture absorption affecting dimensions

- Burr formation on edges

A professional manufacturer manages these issues to stabilize cnc machining nylon cost.

Solutions Used by Manufacturers to Control Cost and Precision

An experienced CNC machining provider applies proven solutions:

- Material conditioning before machining

- Optimized cutting speeds and feeds

- Sharp tooling designed for plastics

- Low-stress fixturing methods

- Controlled inspection processes

These practices prevent scrap and rework, keeping cnc nylon cost predictable.

CNC Machining Nylon Cost vs Metal Machining Cost

In many applications, nylon offers significant cost advantages.

Compared with aluminum or steel:

- 30–60% lower machining cost

- No corrosion protection required

- Lower tool wear

- Faster production cycles

This makes nylon CNC machining a cost-effective alternative when functional requirements allow.

Quality Control and Its Impact on CNC Machining Nylon Cost

Quality control ensures that cost savings do not come at the expense of reliability.

Key quality measures include:

- Dimensional inspection

- Surface finish verification

- Material traceability

- Process consistency

A reliable supplier balances quality control with efficient production to manage cnc nylon cost.

Supplier Selection and CNC Machining Nylon Cost Stability

Choosing the right manufacturer is critical for long-term cost control.

A professional supplier offers:

- In-house CNC machining

- Engineering support

- Stable quality across batches

- Transparent pricing

Working with an experienced manufacturer results in more predictable cnc nylon cost over time.

Conclusion: Managing CNC Machining Nylon Cost Effectively

Cnc nylon cost depends on material selection, design optimization, machining strategy, and supplier capability. By selecting the right nylon grade, optimizing part design, and working with an experienced CNC manufacturer, companies can reduce cost without compromising quality or precision.

Contact Weldo Machining to discuss your nylon CNC machining requirements and receive a detailed, manufacturer-level quotation.