Developing a cnc machining peek prototype is essential for industries that require high-performance plastic components capable of withstanding heat, chemicals, friction, and mechanical stress. PEEK (polyether ether ketone) is a premium engineering polymer used for aerospace, medical, semiconductor, and high-temperature equipment. Creating precise prototypes ensures stable performance before moving to mass production. This article provides a complete breakdown of machining capabilities, tolerances, dimensions, services, and pricing for PEEK prototypes.

What Is a CNC Machining PEEK Prototype and Why Does It Matter?

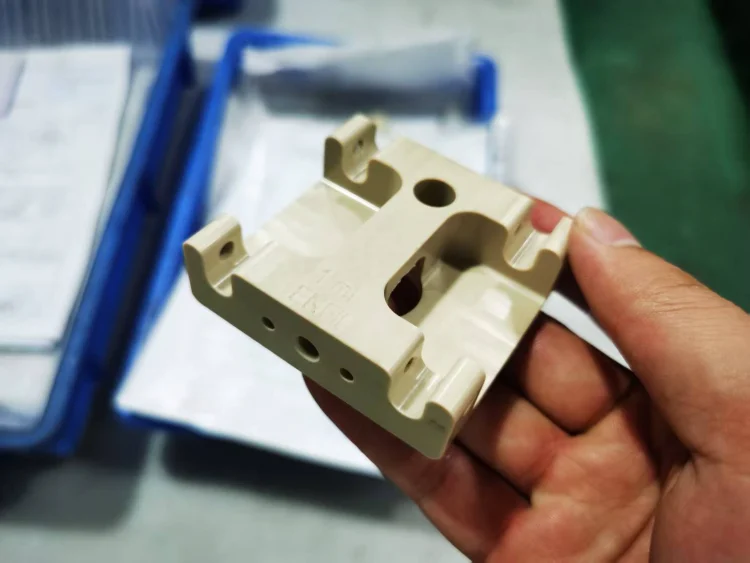

A cnc machining peek prototype is an early-stage, custom-machined PEEK component created to validate functionality, mechanical strength, tolerance stability, and structural performance. Because PEEK is expensive and difficult to machine due to heat sensitivity and toughness, prototypes help engineers reduce risk before committing to full-scale production.

A professional cnc machining peek prototype factory ensures that every detail—from tolerances to threaded features—is produced accurately for testing and verification.

Tolerance Capabilities for CNC Machining PEEK Prototype

PEEK prototypes must meet tight tolerances to perform correctly in high-precision environments. Machining accuracy directly influences both technical performance and the final cnc machining peek prototype cost.

Supported Tolerance Levels

Standard Tolerance

- ±0.05 mm

- Suitable for general mechanical parts, covers, and housings

High Precision Tolerance

- ±0.02 mm

- Used for alignment guides, small connection parts, and structural brackets

Ultra-Precision Tolerance

- ±0.01 mm

- Required for semiconductor fixtures, medical devices, and high-performance sealing parts

Cost Influence

Tighter tolerances increase the cnc machining peek prototype price due to:

- Slower feed rate

- Multi-pass finishing

- More dimensional inspection

- Higher risk of scrap on expensive materials

Machining Size Capabilities for PEEK Prototype Parts

A reliable cnc machining peek prototype factory provides flexible machining ranges for different PEEK component types.

Maximum Machining Size

CNC Milling

- Up to 600 mm × 400 mm × 150 mm

Suitable for: - Structural plates

- Semiconductor trays

- Mechanical brackets

CNC Turning

- Outer diameter up to Ø 350 mm

- Internal diameter up to Ø 280 mm

Used for: - Rings

- Sleeves

- Bushings

Minimum Machining Size

- 0.8 mm wall thickness (depending on geometry)

- Ø 2 mm internal bores (for micro precision parts)

These ranges support medical micro-components and precision insulators.

Machining Services Available for CNC Machining PEEK Prototype

To support complex prototype requirements, manufacturers offer a full range of CNC operations beyond basic cutting.

1. CNC Milling

Capabilities

- Pockets

- Slots

- Grooves

- Flat surfaces

- Multi-face machining

2. CNC Turning

Capabilities

- Inner & outer diameter machining

- Tapered surfaces

- High concentricity parts (±0.01 mm possible)

3. Drilling & Boring

Capabilities

- Deep holes up to 10× diameter

- Micro holes down to Ø 1.0 mm

- Precision bores with stabilized dimensions

4. Threading & Tapping

PEEK prototypes may require:

- Metric (M2–M20)

- UNC/UNF

- Custom fine threads

Thread quality directly affects prototype performance.

5. Surface Finishing for PEEK

PEEK can be finished via:

- Hand-polishing

- Precision deburring

- Grinding small surfaces

- Heat-stress relief treatment

These finishing methods improve performance and aesthetic quality.

Factors That Influence CNC Machining PEEK Prototype Cost

Understanding the cnc machining peek prototype cost helps engineers plan their development budget effectively.

1. Material Grade

- Virgin PEEK

- Glass-filled PEEK

- Carbon-filled PEEK

Reinforced PEEK increases tool wear, raising prototype price.

2. Part Complexity

Parts with:

- Very thin walls

- Multiple cavities

- Undercuts

- Tight inside corners

require longer machining time.

3. Tolerance Requirements

Parts requiring ±0.01 mm precision cost significantly more due to:

- Slow machining

- Extra QC

4. Quantity

A single cnc machining peek prototype has the highest per-unit cost due to one-time programming and setup.

5. Finishing & Inspection

Industries like aerospace and medical require:

- Full inspection reports

- Surface polishing

- Material certification

These also increase cost.

Typical CNC Machining PEEK Prototype Price Breakdown

Below is the most common pricing range:

| Prototype Type | Price Range |

|---|---|

| Simple block or plate | $4–$100 |

| Medium complexity bracket | $80–$200 |

| High-precision cylindrical part | $150–$350 |

| Semiconductor fixture | $250–$600 |

| Medical-grade micro-part | $300–$800+ |

These values give a realistic understanding of cnc machining peek prototype cost in today’s market.

Applications of CNC Machining PEEK Prototype Across Industries

PEEK prototypes are used for early validation in critical industries.

Aerospace

- Insulators

- Heat-resistant brackets

- Lightweight assemblies

Medical

- Surgical parts

- Imaging components

- Biocompatible prototype parts

Semiconductors

- Wafer holders

- Alignment guides

- Precision fixtures

Automotive

- Transmission bushings

- High-voltage insulators

- Wear-resistant components

Why Choose a Professional CNC Machining PEEK Prototype Factory?

Working with an experienced cnc machining peek prototype factory ensures:

- Stable tolerances

- Heat-controlled machining

- Reduced risk of warping

- Full support from drawing review to prototyping

A competent supplier also offers engineering optimization for cost reduction.

How to Request Accurate CNC Machining PEEK Prototype Pricing

To receive an accurate cnc machining peek prototype price, prepare the following:

- 2D drawings + 3D STEP files

- Tolerance requirements

- Material grade

- Quantity (prototype or small batch)

- Finishing requests

The more complete the information, the better the quote accuracy.

Request Professional CNC Machining PEEK Prototype Services — Contact Weldo Machining

When you need high-precision cnc machining peek prototype components for demanding applications, choosing an experienced machining partner is essential.

Weldo Machining offers full PEEK machining solutions, including prototypes, deep-hole boring, tight-tolerance turning, micro-feature milling, threading, inspection reports, and engineering optimization.

Contact us today for detailed pricing and expert assistance for your PEEK prototype machining project.

FAQ of cnc machining peek prototype

How accurate can a CNC-machined PEEK prototype be?

Professional machining can achieve tolerances of ±0.01–0.02 mm depending on geometry and material grade.

What is the typical price for a PEEK CNC prototype?

Most prototypes range from $80–$350, while high-precision semiconductor or medical parts may reach $300–$800+.

What is the smallest feature size that can be machined in PEEK?

Micro holes of Ø 1 mm and thin walls of 0.8 mm are achievable with stable fixturing.

Can a PEEK prototype include threaded holes?

Yes. Machinists can produce metric, UNC/UNF, and fine threads through CNC tapping or thread milling.

How can I reduce CNC machining PEEK prototype cost?

Simplifying geometry, reducing tight tolerances, increasing quantity, and selecting the suitable PEEK grade lower costs.