In product development and low-volume manufacturing, “cnc machining vs 3D printing” is not a simple either-or choice. It is an engineering decision framework built around accuracy/tolerances, material performance, surface finish, cost curve, lead time, and scalability. More importantly, the best outcome is often not to pit the two against each other, but to let them collaborate along the same manufacturing chain with clear division of labor. This article systematically explains “cnc machining vs 3D printing” and provides practical selection guidance and a small example.

Quick take: cnc machining vs 3D printing—start with the scenario

When to lean toward CNC machining

The following scenarios typically favor CNC:

- Tight tolerances and assembly reliability: based on standard capabilities from industrial service providers, CNC “standard tolerances” are often stated as reaching ±0.002 inch, with consistency easier to control.

- Critical hole patterns/datums/sealing surfaces: these “functional surfaces” often determine interchangeability and sealing, sliding, and positioning performance—CNC is more predictable.

- Stable low-to-mid volume delivery: once the process route is stable, batch-to-batch consistency is easier to manage.

When to lean toward 3D printing

In the following scenarios, you are more likely to prefer 3D printing:

- Complex geometry (internal cavities, cable-routing channels, topology structures, lightweight lattices): not limited by tool accessibility, offering greater design freedom.

- High-frequency iteration for concept parts: no fixture or complex toolpath preparation; after design updates, parts can be reprinted quickly to shorten the iteration loop.

- Low volume with many revisions: fewer parts, more variants, and a still-evolving design often make it more cost-effective.

Application accessory comparison

When mapping “cnc machining vs 3D printing” to real part types, the following accessory categories are common:

CNC-machined accessories (function, precision, strength focused)

- Structural connections: mounting brackets, connection plates, adapter blocks, flanges, bases

- Transmission/positioning: bushings/spacers, locating bases, precision hole-pattern components

- Fluid interfaces: connector housings, distribution blocks (manifolds), parts requiring good sealing surfaces

3D-printed accessories (iteration and complex structures focused)

- Appearance/assembly validation: enclosures, covers, panels, button caps, handle/knob prototypes

- Tooling and jigs: locating jigs, inspection fixtures, assembly guide blocks, cable clips/cable-routing brackets

- Complex structures: air ducts/flow guides, cable routing channels, lightweight support structures

This is not a hard rule, but it helps you build practical references for “cnc machining vs 3D printing”: functional surfaces and interchangeability tend to favor CNC, while complex structures and frequent iteration tend to favor 3D printing.

Process fundamentals of cnc machining vs 3D printing

Additive manufacturing (3D printing)

In “cnc machining vs 3D printing,” additive manufacturing usually means:

- Pros: lower barrier for complex structures, integrated designs, fast iteration

- Cons: layer lines/support impacts, shrinkage/warpage risks, and higher sensitivity of dimensional consistency to the process window

Subtractive manufacturing (CNC machining)

CNC (subtractive) usually means:

- Pros: controllable dimensions, strong datum consistency, easier-to-achieve surface quality, and material performance closer to the base stock

- Cons: tool accessibility and number of setups drive cost; deep narrow pockets, thin walls, and long overhangs can significantly raise difficulty and risk

The right DFM question

First ask: “Can we manufacture stably and meet performance requirements?” Then ask: “Which is cheaper?”

When evaluating “cnc machining vs 3D printing,” it is recommended to assess three layers:

- Manufacturability: are there hard risks in accessibility/support/deformation?

- Repeatability: when production volume increases, can dimensional and appearance variation be controlled?

- Verifiability: how will critical features be inspected (gauges, CMM, roughness, etc.)?

Accuracy and tolerance comparison

Typical CNC tolerance capability (more predictable in engineering practice)

Based on common industrial machining service capabilities, CNC “standard tolerances” are often stated as ±0.002 inch.

When your critical features are assembly hole patterns, positioning datums, or sealing surfaces, CNC is usually preferred.

Dimensional accuracy of 3D printing (highly process-dependent and size-dependent)

Typical accuracy ranges vary significantly by process:

- FDM (desktop/prototyping): often around ±0.5% (minimum ±0.5 mm)

- FDM (industrial): can reach ±0.15% (minimum ±0.2 mm)

- SLA: commonly stated range ±0.05–±0.15 mm (depending on size/equipment/environment)

Surface finish and post-processing

Surface roughness differences: metal additive often relies more on post-processing

For metal LPBF (laser powder bed fusion), typical surface roughness (Ra) can be relatively high at the micron level; industry references cite “typical Ra around 5–15 μm.”

This implies that if you need functional surfaces such as sealing, sliding, or mating surfaces, you should plan a post-processing chain such as blasting, polishing, and/or machining.

How post-processing affects cost and lead time

- 3D printing: support removal/cleaning, secondary curing, blasting/polishing, heat treatment, machining of critical surfaces

- CNC: deburring, blasting, anodizing/plating, heat treatment (depending on material and requirements)

Materials and mechanical performance in cnc machining vs 3D printing

Material spectrum and supply chain maturity

- CNC: mature metal and engineering plastic grades; batch and performance data are easier to manage

- 3D printing: rich material system, but more dependent on machine parameters and post-processing windows (especially metal additive)

Anisotropy and fatigue risk: 3D printing needs more validation

A common dividing line for load-bearing parts in “cnc machining vs 3D printing” is:

- 3D printing may introduce anisotropy risk due to build paths and inter-layer bonding

- CNC is closer to the baseline of the original material and typically supports long-term reliability arguments more directly

Lead time and scaling: don’t treat cnc machining vs 3D printing as opposites

The right relationship: collaboration along the same manufacturing chain

A more efficient approach is:

- 3D printing solves “complex structures and iteration speed”

- CNC machining solves “critical-feature accuracy and consistency”

This turns “cnc machining vs 3D printing” from a confrontation into a process combination.

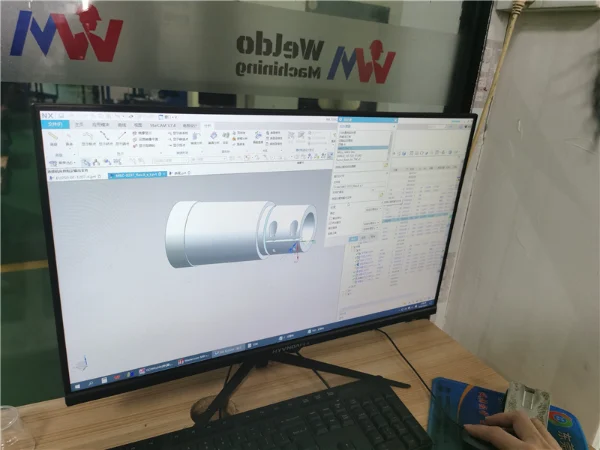

A small example: sensor/camera bracket (printed body + CNC-locked critical features)

Requirement: the bracket must conform to the mechanism and include a cable-routing groove; sensor installation requires two locating holes and a datum plane to ensure calibration repeatability.

- Pure CNC: the conformal shape and cable groove increase setups and toolpath costs; revisions are slow.

- Pure 3D printing: shape is fine, but locating holes and datum planes are more affected by process variation.

- Hybrid route: 3D print the main body (including the groove/conformal surfaces), reserve machining allowance and fixturing features in critical areas, then CNC-machine the locating holes and datum plane.

Result: fast iteration and design freedom, while critical assembly features are controlled reliably.

Common hybrid combinations

- Print the complex body + CNC-machine hole patterns/sealing surfaces/mating surfaces

- Print jigs/soft jaws/assembly guides + CNC-machine deliverable parts

- Print first for validation → switch to CNC for engineering samples and batch delivery after design freeze

Conclusion

In general, the best answer to “cnc machining vs 3D printing” is often: use 3D printing for complex structures and fast iteration, and use CNC machining to lock down critical features and consistent delivery. When you need both “complexity + precision,” hybrid manufacturing is frequently the best overall value.

If you can share drawings (STEP/IGES/PDF), target quantity, material, and key tolerance/surface requirements, Weldo Machining can provide manufacturability feedback, process-route comparisons for “cnc machining vs 3D printing,” and a quote with lead time options.