CNC metal machining:

Overview

High-accuracy cnc metal machining for aluminum, steel, stainless steel, copper, brass, titanium, and complex metal components with tight tolerances and fast lead times.

Tolerance: up to 0.001 inch.

Material: Aluminum alloy,stainless steel,steel,magnesium alloy,copper,bronze,brass,etc.

MOQ: prototype to (small batch) mass production.

Delivery time: 1-5 days

Application: Aerospace,medical,automotive,Consumer electronics,new energy,etc.

Price: 10~500 USD/PCs.

What Is CNC Metal Machining?

CNC metal machining refers to the computer-controlled removal of material from a metal workpiece using mills, lathes, or multi-axis equipment. This process delivers excellent dimensional accuracy, smooth surfaces, and stable repeatability, making it essential for complex geometries, functional parts, and critical-tolerance components.

CNC metal machining is ideal for:

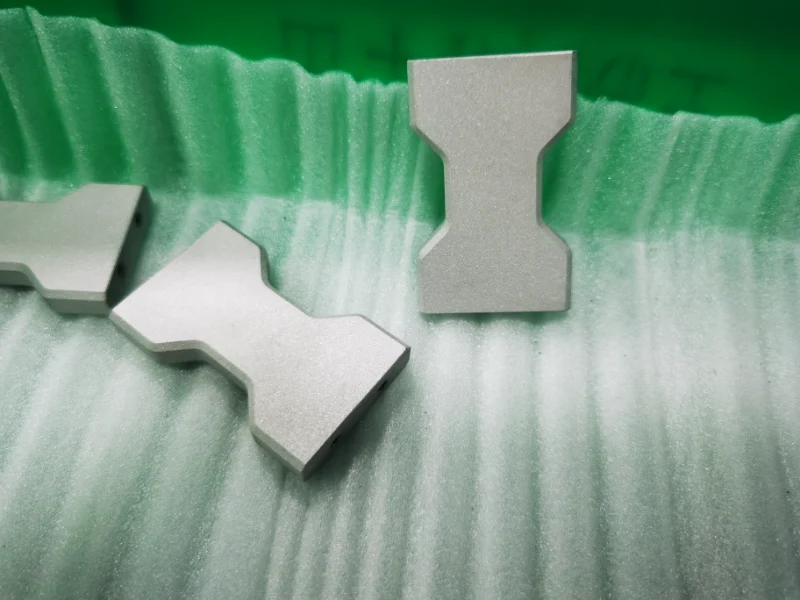

Custom prototypes

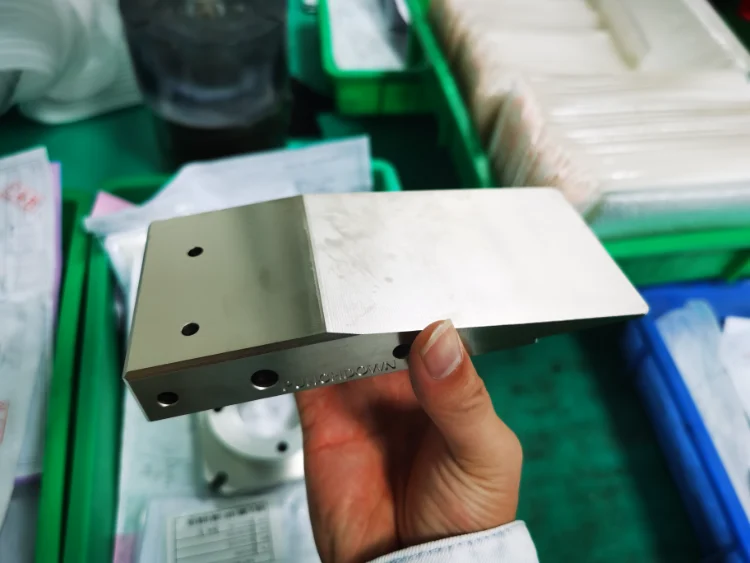

High-precision structural parts

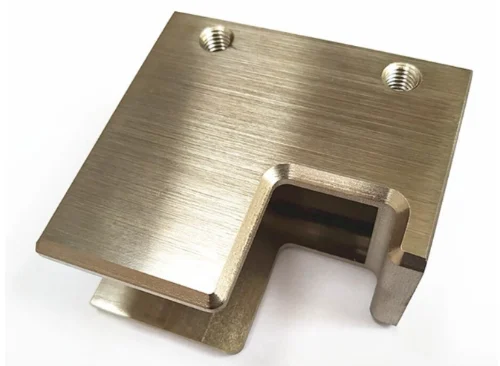

Mechanical housings and brackets

Low-volume or mass-production runs

High-strength or heat-resistant components

Core Capabilities

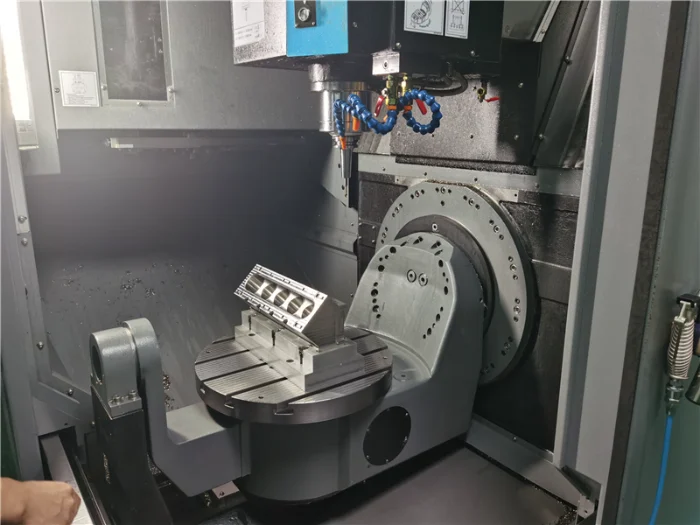

CNC Milling

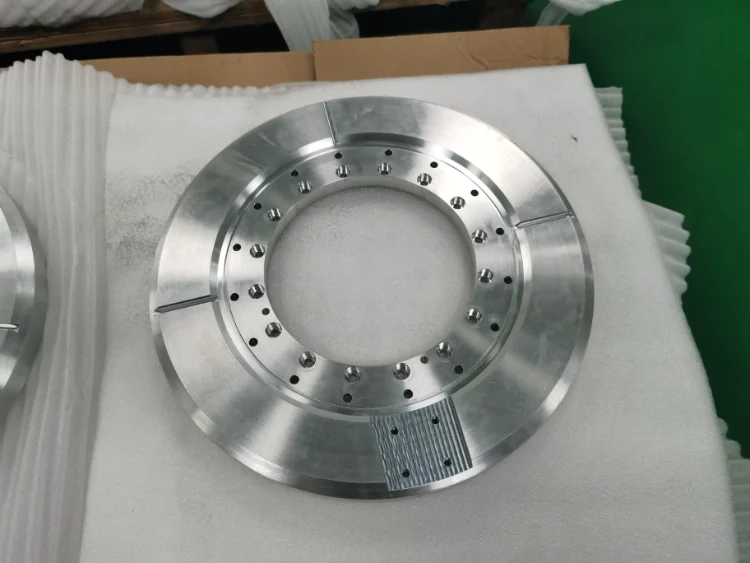

CNC milling excels at producing metal components featuring pockets, cavities, channels, threads, and detailed contours.

Typical Advantages

Tight tolerances for complex geometries

Excellent for high-strength materials

Fast prototyping and scalable production

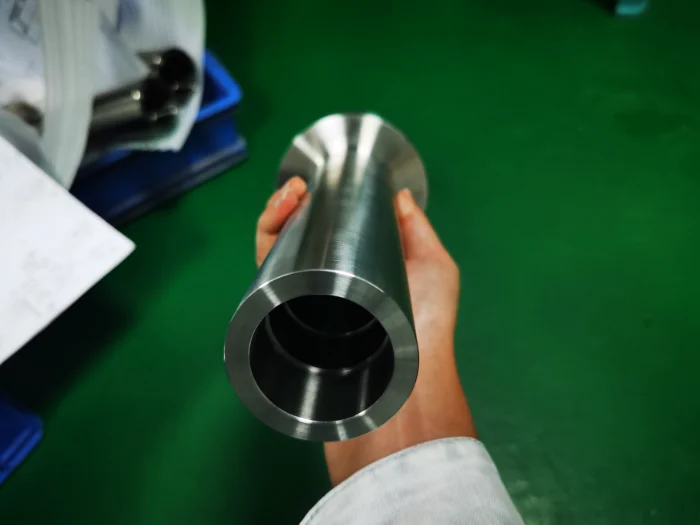

CNC Turning

For cylindrical, round, or symmetrical components. provides efficient metal removal for shafts, bushings, sleeves etc.

Benefits

High-speed production

Smooth surface finishes

Consistent dimensional accuracy

3/4/5-Axis CNC Machining

For complexity shapes, undercuts, or multi-surface features, 5-axis machining reduces setups and ensures precision on parts.

Suitable for

Aerospace and medical metal components

Precision brackets and impellers

Thin-wall structures and curved surfaces

Available Metal Materials for cnc machining

Weldo Machining offers a wide selection of metal materials suitable for strength, heat resistance, corrosion protection, weight reduction, and cost efficiency.

Aluminum Alloys

6061-T6 :General, lightweight, cost-effective

7075-T6 :High strength for aerospace/defense

5052 / 5083 :Strong corrosion resistance

Stainless Steels

303 / 304 — General corrosion-resistant parts

316 / 316L — Marine and medical grade

17-4PH — High strength, excellent hardness

Steel & Alloy Steel

1018 / 1045 — General engineering parts

4140 / 4340 — High toughness components

Tool Steels (D2, O1) — Wear-resistant parts

Brass & Copper

C360 brass — machinable, ideal for fittings

C110 copper — Excellent conductivity

Bronze — High wear resistance

Titanium

Ti-6Al-4V — Extremely strong and lightweight

Ideal for aerospace.

medical implants, and high-performance parts.

Tolerances for CNC Metal Machining

Weldo Machining works with industry-standard and tight tolerances for metal components.

Special tolerances can be quoted upon request.

| Grade | Tolerance Range | Cost Level | Typical Applications |

|---|---|---|---|

| Standard | ±0.1 mm | Low | Structural parts, brackets, housings |

| Medium | ±0.05 mm | Medium | Assembly parts, fitting components |

| Precision | ±0.01 ~ ±0.02 mm | High | Precision components, bearing seats, locating surfaces |

| Ultra Precision | ≤ ±0.005 mm | Very High | Medical, aerospace, optical, high-end mold components |

Surface finish for CNC machining parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various precision machined parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Industries Served

CNC metal machining supports precision components for advanced markets:

Automotive (brackets, housings, drivetrain components)

Aerospace & Defense (lightweight high-strength parts)

Medical Devices (surgical tools, custom fixtures)

Robotics & Automation (frames, couplings, gears)

Electronics (heatsinks, enclosures, connectors)

Industrial Machinery (shafts, mounts, high-load parts)

Why Work With Weldo Machining?

Fast Prototyping to Production

We deliver rapid quotes, quick-turn prototypes, and scalable manufacturing for batches ranging from one unit to thousands.

Strict Quality Control

Every part undergoes dimensional inspection, material verification, and documentation to ensure stability and reliability.

Global Shipping & Competitive Pricing

Our optimized machining workflows and material sourcing help reduce cost while maintaining premium quality.

Engineering Support

We review your CAD models for DFM improvements, tolerance clarification, and cost-optimization suggestions.

How to Get a Quote

Simply upload your CAD files (STEP/IGES/STL) and 2D drawings (PDF).

Our engineering team responds quickly with pricing, lead time, and manufacturability feedback.

FAQ of CNC metal machining

What metals are best for high-precision CNC machining?

Aluminum 6061/7075, stainless steel 316/17-4PH, alloy steel 4140, and titanium Ti-6Al-4V are commonly used for high-precision CNC metal machining due to strength and machinability.

How do I choose the right material for my CNC metal part?

Consider strength, corrosion resistance, weight, temperature range, surface finish needs, and cost. Our engineers can recommend the best metal for your application.

What affects CNC metal machining cost?

Material type, part complexity, tolerances, finishing requirements, and quantity all influence cost.

What file formats do you accept for CNC machining quotes?

STEP, STP, IGES, STL, SLDPRT, and PDF for technical drawings.