Understanding cnc milling and turning cost is essential for engineers, buyers, and manufacturers seeking precise, repeatable components at predictable prices. Unlike simple machining, combined milling and turning operations involve multiple cutting strategies, tooling paths, and setup decisions, all of which directly influence cnc milling and turning cost.

This article explains how cnc milling and turning cost is formed, how pricing scales across design stages, and how smart decisions can significantly reduce total manufacturing expenses.

The Real Meaning Behind CNC Milling and Turning Cost

At its core, cnc milling and turning cost represents the total expense required to convert raw material into a finished precision part using subtractive machining. This includes machine time, tooling, programming, setup, inspection, and post-processing.

Unlike quoting based solely on hourly rates, true cnc milling and turning cost reflects the complete production lifecycle—from CAM programming to final quality approval.

How CNC Milling and Turning Cost Is Calculated

Every machining supplier calculates cnc milling and turning cost using a structured pricing model.

Key Cost Components

- CNC machine hourly rate

- Programming and setup time

- Raw material cost and wastage

- Tool wear and replacement

- Quality inspection and documentation

Each of these elements scales differently, which is why cnc milling and turning cost can vary widely between similar parts.

CNC Milling and Turning Cost by Machining Process

Milling-Dominated Cost Factors

When milling is the primary operation, cnc milling and turning cost increases due to:

- Multi-axis tool paths

- Longer cycle times

- Complex pockets and contours

- Higher CAM programming effort

Turning-Dominated Cost Factors

Turning operations help stabilize cnc milling and turning cost when:

- Parts are axially symmetric

- Cutting paths are continuous

- Tool engagement remains constant

Mill-turn machining balances both processes, often reducing total cnc milling and turning cost by minimizing part handling.

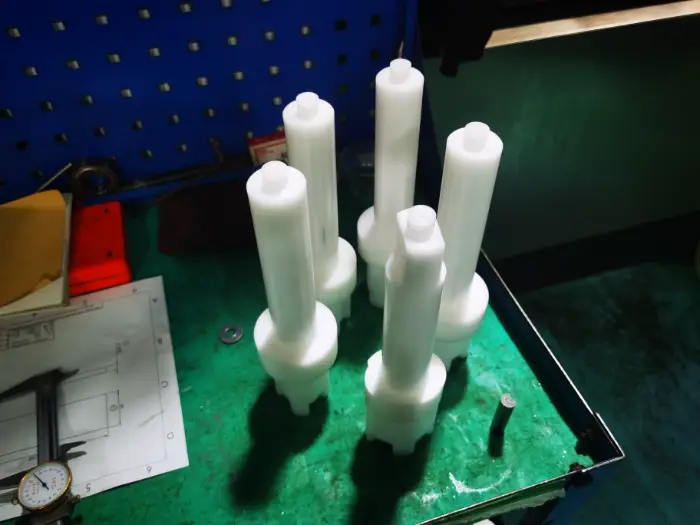

Material Selection and CNC Milling and Turning Cost Impact

Material choice is one of the strongest drivers of cnc milling and turning cost.

Material Cost Influence

- Aluminum alloys deliver the lowest cnc milling and turning cost due to fast cutting speeds

- Carbon and alloy steels create moderate cnc milling and turning cost

- Stainless steel increases cost via tool wear and heat generation

- Engineering plastics vary widely in cnc milling and turning cost depending on stability

Material yield and scrap ratios also directly raise cnc milling and turning cost in high-precision jobs.

Design Geometry and Cost Complexity

The geometry of a part determines machining efficiency and directly affects cnc milling and turning cost.

Design features that increase cnc milling and turning cost include:

- Thin walls and deep cavities

- Sharp internal corners

- Tight feature spacing

- Multi-face machining requirements

Optimizing geometry using Design for Manufacturability (DFM) principles can reduce cnc milling and turning cost by 15–30%.

Tolerance Levels and Precision-Driven Cost

Tolerances define machining accuracy, and precision drives cnc milling and turning cost.

| Tolerance Range | Cost Impact |

|---|---|

| ±0.1 mm | Standard cnc milling and turning cost |

| ±0.05 mm | Moderate cost increase |

| ±0.01 mm or tighter | High cnc milling and turning cost |

Over-specifying tolerances is one of the most common reasons cnc milling and turning cost exceeds initial budgets.

Production Volume and CNC Milling and Turning Cost Scaling

Production quantity dramatically reshapes cnc milling and turning cost per unit.

Cost Behavior by Volume

- Prototype quantities: Highest cnc milling and turning cost per part

- Low-volume batches: Balanced cost efficiency

- High-volume production: Lowest cnc milling and turning cost per unit

Spreading fixed setup costs across volume is the most effective way to reduce cnc milling and turning cost.

CNC Machine Type and Cost Efficiency

The type of equipment used plays a vital role in cnc milling and turning cost.

- 3-axis CNC machines: Low hourly rates, higher setup frequency

- 5-axis machines: Higher hourly cnc milling and turning cost, fewer setups

- Mill-turn centers: Highest hourly rate, lowest total cnc milling and turning cost for complex parts

Choosing the right machine often matters more than the hourly rate itself.

Secondary Operations and Hidden Cost Factors

Beyond cutting time, cnc milling and turning cost includes secondary processes:

- Deburring and edge finishing

- Surface treatments

- Dimensional inspection

- Documentation and compliance

These hidden contributors can represent 25–40% of total cnc milling and turning cost if not planned early.

Practical Methods to Reduce CNC Milling and Turning Cost

Reducing cnc milling and turning cost is possible without sacrificing quality.

Proven Cost-Control Techniques

- Simplify part geometry

- Avoid unnecessarily tight tolerances

- Select machinable materials

- Combine milling and turning in one setup

- Increase batch size strategically

Early collaboration with a machining supplier consistently lowers cnc milling and turning cost.

CNC Milling and Turning Cost vs Alternative Manufacturing

When compared to casting or molding, cnc milling and turning cost excels in flexibility and accuracy.

CNC machining offers:

- Tooling-free production

- Faster design changes

- Superior dimensional consistency

For low to medium volumes, cnc milling and turning cost often delivers the best cost-to-performance ratio.

Final Thoughts on CNC Milling and Turning Cost

The true cnc milling and turning cost is shaped by design, material, tolerance, volume, and process integration. Buyers who understand these drivers can accurately forecast expenses and avoid unexpected pricing issues.

With proper planning and supplier alignment, cnc milling and turning cost becomes a controllable, strategic advantage rather than a risk.