In modern product development, the demand for fast, reliable, high-quality cnc plastic machining prototype production continues to grow. From consumer electronics to medical components and industrial automation, designers rely on precision-machined plastic parts to validate form, fit, and function. The accuracy, repeatability, and material versatility offered by cnc plastic machining prototype services make them ideal for early-stage testing and low-volume manufacturing.

Compared to molding or 3D printing, CNC machining delivers superior dimensional stability, tighter tolerances, and improved surface finish—especially for engineering plastics such as ABS, POM, PEEK, and PMMA. This article explains everything you need to know about CNC plastic prototypes, the advantages of different materials, and why Weldo Machining is the right partner for your next project.

What Is a CNC Plastic Machining Prototype?

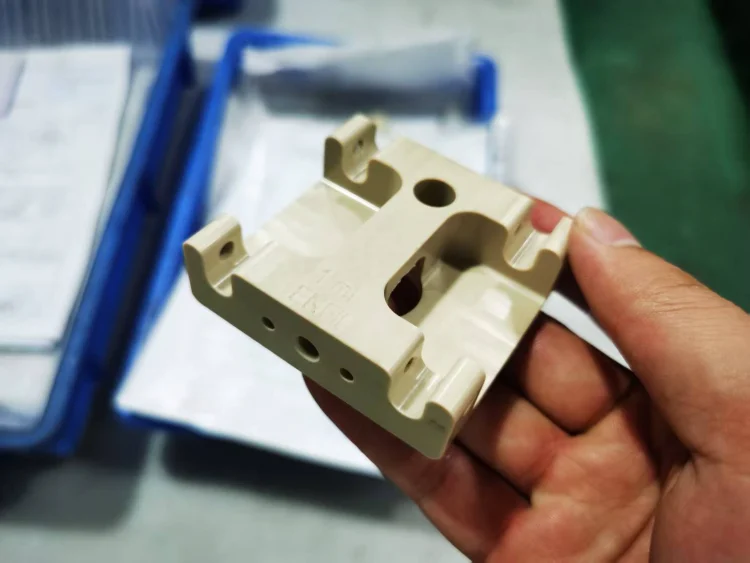

A cnc plastic machining prototype is a precision part created from a solid plastic block using subtractive machining processes. The goal is to replicate the final production part as closely as possible in terms of dimensions, surface quality, and material behavior.

Unlike additive manufacturing, CNC machining uses computer-controlled cutting tools to remove material, producing highly accurate functional prototypes. These prototypes can withstand real mechanical testing, high temperatures, chemical exposure, or dynamic loads, depending on the chosen plastic material.

Benefits of CNC Plastic Machining Prototype Services

1. High Dimensional Accuracy

CNC machining provides excellent repeatability and tight tolerance control. Prototypes can be machined to ±0.02 mm or even tighter, depending on geometry and material.

2. Wide Material Compatibility

A major advantage of cnc plastic machining prototype production is the flexibility to select from hundreds of engineering plastics, such as:

- ABS

- POM/Delrin

- PEEK

- PMMA/Acrylic

This gives engineers the closest possible representation of final production behavior.

3. Fast Lead Time

CNC machining bypasses tooling, allowing prototypes to be delivered in days rather than weeks. This accelerates design iterations and reduces development cost.

4. Superior Surface Finish

CNC machining creates clean edges, smooth surfaces, and consistent quality—ideal for assembled components or functional testing.

CNC Plastic Materials for High-Precision Prototype Machining

Below is a detailed look at four key materials integrated into your structure.

ABS CNC Machining for Functional Prototypes

ABS CNC machining is ideal for early-stage functional parts, enclosures, brackets, and device housings. ABS offers:

- Excellent toughness

- Easy machinability

- Stable dimensional performance

- Good cost efficiency

ABS prototypes provide reliable mechanical behavior and are widely used in consumer electronics, automobile interiors, and robotics applications.

POM CNC Machining for High-Wear Components

POM CNC machining (also known as Delrin machining) delivers excellent structural rigidity and low friction. It is commonly selected for:

- Gears

- Bushings

- Wear-resistant mechanical parts

- Precision fixtures

Its natural lubricity and excellent strength make POM one of the most cost-effective choices for moving mechanical prototypes.

PMMA CNC Machining for Transparent and Optical Parts

PMMA CNC machining (Acrylic machining) enables production of clear components such as:

- Light guides

- Lenses

- Display windows

- Transparent covers

PMMA is easy to polish to an optical-grade finish, making it ideal for prototypes requiring visibility, clarity, and smooth surfaces.

PEEK CNC Machining for High-Performance Engineering Prototypes

PEEK CNC machining is used for high-temperature and high-strength applications. PEEK provides:

- Exceptional thermal resistance

- Excellent chemical stability

- Superior mechanical strength

- Long-term structural performance

Industries such as aerospace, medical, semiconductor, and industrial automation rely on PEEK prototypes when durability and functionality are critical.

Applications of CNC Plastic Machining Prototype Services

Consumer Electronics

Precision housings, internal structural parts, optical components, and testing jigs.

Medical Devices

Functional prototypes for surgical tools, testing fixtures, sterile housings, and laboratory instruments.

Automotive and Industrial

Gear prototypes, interior components, bushings, and wear-friction parts produced using POM CNC machining and PEEK CNC machining.

Robotics & Automation

Sensor housings, transparent guards, high-strength mechanical prototypes.

Choosing the Right Material for CNC Plastic Machining Prototype Projects

ABS vs. POM

ABS is a better choice for enclosures and aesthetic prototypes.

POM is superior for moving mechanical components.

PEEK vs. PMMA

PEEK is ideal for thermal and structural performance.

PMMA is best for aesthetic and transparent prototypes.

Selecting the correct material greatly affects:

- Strength

- Cost

- Machining time

- Thermal stability

- Surface quality

Weldo engineers can analyze your design to recommend the most suitable solution.

CNC Machining Capabilities for Plastic Prototype Production

Precision and Tolerance

Weldo’s CNC centers achieve high accuracy with stable repeatability. Typical tolerances include:

- ±0.05 mm for standard plastic parts

- ±0.02 mm for engineering plastics

- Tighter tolerances available for PEEK and POM prototypes

Surface Finish Options

We offer:

- Milled surfaces

- Polished PMMA optical clarity

- Deburring and chamfering

- Bead blasting (depending on material)

Multi-Axis Machining

We support 3-axis, 4-axis, and 5-axis machining for complex geometries, undercuts, and contoured surfaces.

How to choose a CNC Plastic Machining Prototype manufacturer?

Experience Across Multiple Industries

Have produced thousands of prototypes for medical, consumer electronics, automotive, laboratory, and aerospace applications.

Advanced Material Knowledge

Understands how different plastics behave during machining. This reduces scrap and ensures consistent quality.

Competitive Pricing

Whether you need ABS CNC machining, PEEK CNC machining, POM CNC machining, or PMMA CNC machining, They can offer affordable and transparent pricing.

Engineering Support

Professional cnc plastic machining manufacturer provides:

- DFM (design for manufacturability)

- Material recommendation

- Tolerance optimization

- Rapid quotation

Get a CNC Plastic Machining Prototype Quote from Weldo

If you need fast, reliable cnc plastic machining prototype services for your next project, Weldo can help you meet deadlines with guaranteed precision and material performance. Upload your drawings, CAD files, or 3D models, and our engineers will assist with cost reduction and manufacturability suggestions.

Contact Weldo today for a customized quotation and expert guidance on any CNC plastic machining prototype requirement.

FAQ of cnc plastic machining prototype

What is a CNC plastic machining prototype used for?

It is used for functional testing, design validation, assembly evaluation, and pre-production verification across electronics, medical, and industrial applications.

Which plastic material is best for CNC prototyping?

ABS is ideal for housings, POM for moving parts, PMMA for transparent applications, and PEEK for high-performance engineering prototypes.

How long does it take to create a CNC plastic machining prototype?

Most prototypes can be produced within 2–5 days depending on material, complexity, and finishing requirements.

How do I get a quote for CNC plastic machining prototype services?

Send your CAD files, preferred material (ABS, POM, PMMA, PEEK), and quantity. Weldo will provide a fast, accurate quotation and manufacturability advice.

Can CNC machined prototypes match injection-molded part quality?

Yes. CNC machining delivers excellent dimensional precision and surface quality, making it suitable for final-stage engineering validation.