Understanding the true cnc stainless steel machining price is essential for engineers, product developers, and procurement managers working with high-strength metal components. Stainless steel remains one of the most widely used metals due to its corrosion resistance, mechanical durability, and suitability for both prototypes and mass production. However, the machining price can vary significantly depending on the grade, tolerances, finishing, and part geometry. This guide explains how different factors influence cost and how to estimate the most reasonable budget for your next stainless steel machining project.

Key Factors That Influence CNC Stainless Steel Machining Price

Because stainless steel is harder and tougher than aluminum or brass, the cnc stainless steel machining price typically depends on cutting requirements, tooling strategy, and project complexity.

1. Stainless Steel Material Grade

Different stainless steels come with different mechanical properties and machining challenges. This is one of the biggest contributors to total cnc stainless steel machining cost.

Common Grades

- 304 Stainless Steel

Good corrosion resistance, general-purpose, moderate machining difficulty - 316 Stainless Steel

Superior corrosion resistance, ideal for marine and medical components - 410 / 420 Stainless Steel

Harder structure, used for tools and high-strength parts - 17-4 PH Stainless Steel

Precipitation-hardening alloy with excellent strength and dimensional stability

More difficult-to-machine grades typically increase per-part machining cost.

2. Part Geometry and Machining Complexity

The complexity of the design directly influences cnc stainless steel machining price.

Cost Drivers Include

- Deep cavities

- Thin-wall structures

- Multi-axis requirements

- Micro features

- Tight corner radii

More complexity = longer machining time = higher cost.

3. Tolerance Requirements

High precision contributes heavily to the final cnc stainless steel machining cost.

Typical Tolerance Categories

- ±0.05 mm → Standard CNC machining

- ±0.02 mm → Mid-level precision

- ±0.005–0.01 mm → High precision, significantly higher cost

Tighter tolerances require slower cutting speeds and more inspection, increasing price.

4. Surface Finishing Requirements

Stainless steel supports a wide range of industrial finishing options. Each finish impacts the cnc stainless steel machining price.

Common Finishes

- Brushing

- Mirror polishing

- Passivation

- Sandblasting

- CNC machined surface (as-milled)

Finishing adds labor, time, and sometimes additional treatment costs.

5. Order Quantity

The more pieces you order, the lower the per-unit machining price.

Price Trend

| Quantity | Price Behavior |

|---|---|

| 1–10 pcs | Highest per-unit cost |

| 10–50 pcs | Moderate cost |

| 50+ pcs | Economical pricing due to reduced setup time |

For most projects, larger batch orders lower overall cnc stainless steel machining cost.

Typical Price Range for CNC Stainless Steel Machining

Although pricing varies by design, the following ranges act as general cost references:

| Component Type | Typical Price Range |

|---|---|

| Simple brackets | $30–$70 |

| Machined blocks | $40–$120 |

| Precision mechanical parts | $80–$200 |

| Medical-grade components | $120–$350 |

| Complex multi-axis parts | $150–$400+ |

Actual cnc stainless steel machining price depends on alloy selection, machining time, finishing, and tolerances.

Material Options for CNC Stainless Steel Machining

Proper material choice helps balance performance and cost. Here are commonly used grades:

304 Stainless Steel

Key Features

- Widely available

- Good corrosion resistance

- Cost-effective

Applications

- Structural parts

- Mechanical brackets

- Consumer product components

316 Stainless Steel

Key Features

- Strong resistance to chemicals and saltwater

- Excellent for harsh environments

Applications

- Marine hardware

- Medical devices

- High-precision industrial components

430 Stainless Steel

Key Features

- Ferritic stainless steel

- Good corrosion resistance with lower cost

Applications

- Decorative finishes

- Appliance parts

- Automotive trim

17-4 PH Stainless Steel

Key Features

- High strength

- Excellent fatigue resistance

- Superior dimensional stability

Applications

- Aerospace components

- Heavy-load industrial parts

- High-performance mechanical systems

These material options contribute to different cnc stainless steel machining cost levels depending on machining difficulty.

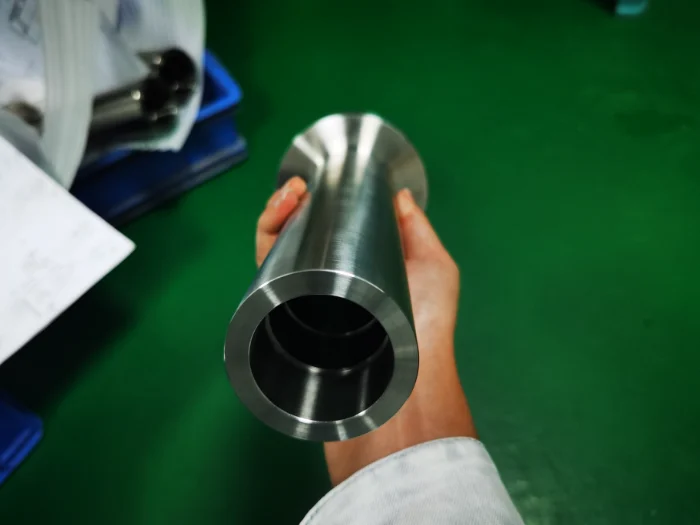

Applications of CNC Stainless Steel Machining

Stainless steel components are used across numerous industries due to their durability and consistent performance.

Automotive and Transportation

- Engine adapters

- Transmission housings

- Structural brackets

Aerospace and Defense

- High-strength mechanical parts

- Load-bearing connectors

- Precision fasteners

Medical and Laboratory Equipment

- Surgical tools

- Brackets

- Sterilization-resistant components

Industrial Machinery & Robotics

- Shafts

- Mounting plates

- Precision fittings

These applications often require high precision, influencing cnc stainless steel machining price depending on tolerances and design complexity.

How to Reduce CNC Stainless Steel Machining Price

Select Standard Tolerances

Avoid ultra-tight tolerances unless necessary.

Simplify Part Geometry

Reducing deep cavities or complex features lowers machining time.

Choose Cost-Effective Stainless Grades

304 and 430 are cheaper to machine compared to 316 or 17-4 PH.

Increase Order Quantity

Batch machining can reduce the per-unit cnc stainless steel machining cost significantly.

Request CNC Stainless Steel Machining Price — Contact Weldo Machining

Choosing the right machining partner is essential for balancing cost, precision, and performance. As an experienced provider of precision metal parts, Weldo Machining offers competitive cnc stainless steel machining price solutions across multiple stainless steel grades including 304, 316, 430, and 17-4 PH. Whether you need prototypes, structural components, or complex multi-axis assemblies, our engineering team provides reliable quality, fast lead times, and expert cost optimization.

Contact us today for accurate pricing and professional support for your cnc stainless steel machining needs.

FAQ of CNC Stainless Steel Machining Price

What affects CNC stainless steel machining price the most?

Material grade, tolerances, machining complexity, finishing, and order quantity are the main cost drivers.

Is stainless steel more expensive to machine than aluminum?

Yes. Stainless steel is harder and requires slower cuts, increasing machining cost compared to aluminum.

Which stainless steel grade is cheapest to machine?

304 and 430 are more cost-effective than 316 or 17-4 PH due to easier machinability.

Does finishing affect machining cost?

Yes. Polishing, passivation, and brushing add additional time and labor, raising the overall cnc stainless steel machining cost.