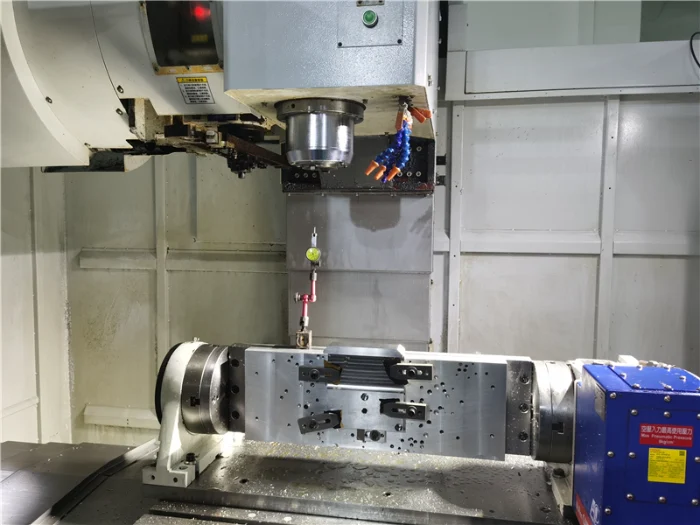

As a CNC vertical machining manufacturer, precision and efficiency are key when choosing the right equipment. CNC vertical machining is widely used across industries like aerospace, automotive, and medical devices for producing parts with tight tolerances and complex geometries. Whether you’re using 3 axis, 4 axis, or 5 axis CNC vertical machining, selecting the right CNC vertical machining equipment is essential for meeting your production needs.

What is CNC Vertical Machining?

CNC vertical machining utilizes vertical machining centers (VMCs) to precisely cut and shape materials. The cutting tool moves along multiple axes—X, Y, and Z—and the addition of 4-axis and 5-axis CNC vertical machining allows for greater flexibility and more complex part geometries. This system is ideal for industries requiring intricate parts with exact specifications, such as aerospace and medical.

Types of CNC Vertical Machining Equipment

3 Axis CNC Vertical Machining

3 axis CNC vertical machining moves the cutting tool along three axes: X, Y, and Z. This is perfect for simpler parts with straightforward machining needs.

Advantages:

- Cost-effective: Great for small runs and simple parts.

- Easy to operate: Requires minimal setup and is user-friendly.

4 Axis CNC Vertical Machining

Adding a rotational axis (usually along the X-axis), 4-axis CNC vertical machining enables more complex machining on multiple sides of the workpiece in one setup.

Advantages:

- Increased efficiency: Fewer setups, faster machining.

- Complex parts: Ideal for parts with more intricate designs.

5 Axis CNC Vertical Machining

5-axis CNC vertical machining adds two more rotational axes, allowing the workpiece to be machined from multiple angles without repositioning.

Advantages:

- Highly precise: Great for intricate parts requiring extreme precision.

- Time-saving: Can machine all sides in one go, reducing setup time.

High Precision CNC Vertical Machining

For industries that demand precise and intricate parts, high precision CNC vertical machining is essential. This technology ensures parts meet the tightest tolerances, ideal for sectors like aerospace, medical devices, and defense.

Benefits:

- Tight tolerances: Parts manufactured with high precision to match exact specifications.

- Consistency: Every part is made to the same high standard.

- Surface finish: Smooth finishes that often require no further processing.

CNC Vertical Machining vs. Horizontal CNC Machining

When deciding between CNC vertical machining and horizontal CNC machining, it’s essential to weigh the advantages and limitations of each.

Advantages of CNC Vertical Machining

- Cost-Effective for Smaller Parts

CNC vertical machining is ideal for smaller to medium-sized parts and is more affordable than horizontal CNC machining for low-to-medium production. - Simpler Setup and Operation

Vertical machines are easier to set up and operate, especially for simple parts or prototypes. - Space-Efficient

CNC vertical machining centers require less floor space, making them ideal for smaller workshops.

Disadvantages of CNC Vertical Machining

- Limited for Large Parts

Vertical machines work best for smaller parts; larger, heavier components may require horizontal CNC machining for better stability. - Chip Removal Issues

Vertical machining can face challenges with chip removal, especially during high-volume production. Horizontal machining generally handles this better due to gravity.

Advantages of CNC Horizontal Machining

- Ideal for Large Parts

Horizontal CNC machining offers better support for large parts, making it ideal for heavy, bulky components. - Improved Chip Removal

The horizontal configuration allows chips to fall away from the workpiece, preventing interference with the cutting process. - Multi-Sided Machining

Horizontal CNC machining can perform machining on multiple sides of a workpiece in one setup, saving time and improving efficiency.

Disadvantages of CNC Horizontal Machining

- Higher Initial Investment

Horizontal CNC machines are typically more expensive to purchase and maintain. - More Complex Setup

Horizontal machines generally require more time for setup and are less flexible for simpler parts or small runs.

How CNC Vertical Machining Manufacturers Can Reduce Production Costs

CNC vertical machining manufacturers can reduce production costs by optimizing key factors:

- Optimizing Machine Utilization: Using automation and maximizing machine uptime ensures machines operate efficiently, reducing the cost per part.

- Reducing Material Waste: Proper material selection, optimized cutting parameters, and high-quality tools minimize scrap and lower material costs.

- Streamlining the Production Process: 5-axis CNC vertical machining reduces the need for multiple setups, improving efficiency and saving time.

- Applying Lean Manufacturing: By using lean principles, manufacturers can reduce waste, improve workflow, and lower operational costs.

- Flexible Pricing: Offering volume discounts or customized solutions helps customers reduce costs while maintaining high quality.

Choosing the Right CNC Vertical Machining Manufacturer

When selecting a CNC vertical machining manufacturer, consider factors such as part complexity, production volume, precision requirements, and budget.

- Part Complexity: For intricate parts, 5-axis CNC vertical machining is ideal, while 3-axis CNC vertical machining works for simpler designs.

- Production Volume: For small runs, CNC vertical machining equipment is cost-effective, while 4-axis or 5-axis systems may be better for larger, more complex runs.

- Precision Needs: If tight tolerances are essential, choose a manufacturer experienced with high precision CNC vertical machining.

- Budget: Balance the complexity of your parts and required volume with your budget to select the right machining option for your needs.

Conclusion: Contact Us for Your CNC Vertical Machining Needs

Selecting the right CNC vertical machining manufacturer is crucial for producing high-quality, precise parts at an affordable cost. Whether you require 3-axis CNC vertical machining, 4-axis CNC vertical machining, or 5-axis CNC vertical machining, choosing the right equipment and manufacturer ensures your production runs efficiently.

Contact Weldo machining today for a quote, and let us help you optimize your production with our advanced CNC vertical machining equipment.