Custom CNC machining delivers precision, repeatability, and design freedom for makers and manufacturers. When you need parts that match exact drawings, custom CNC machining turns concepts into reliable components. This article explains processes, materials, costs, and services — with clear guidance on CNC machining aluminium work, selecting a CNC machining services partner, and what to expect from custom CNC machining UK suppliers.

Why Choose Custom CNC Machining?

Custom CNC machining offers unmatched accuracy. With programmable toolpaths, mills and lathes cut complex geometries consistently. Choosing CNC machining means you get parts made to exact tolerances, reliable surface finishes, and fast iteration for prototypes and production runs.

Short runs or long production? Custom CNC machining adapts. It’s ideal for one-off prototypes and scaled batches. You keep design control while a skilled shop handles material selection, fixturing, and inspection.

What Custom CNC Machining Services Include

A full CNC machining services offering covers more than cutting. Typical services include:

- CAD review and DFM feedback.

- CNC milling, turning, and multi-axis work.

- Secondary operations: deburr, heat treat, coating.

- Inspection: CMM reports, first-article inspection.

- Assembly and kitting for final delivery.

A strong CNC machining services provider adds engineering value, helping you reduce cost and improve manufacturability.

The Custom CNC Machining Process — Step by Step

- Design review: The shop reviews your CAD and suggests improvements for CNC machining.

- Material selection: Choose metals or plastics; aluminium is common.

- CAM programming: Toolpaths are generated for the machining center.

- Setup & machining: Fixtures, tooling, and machines are prepared.

- Finishing & QA: Parts are finished and inspected per requirements.

Each step influences lead time and final CNC machining cost.

Custom CNC Machining Aluminium — Why Aluminium Is Popular

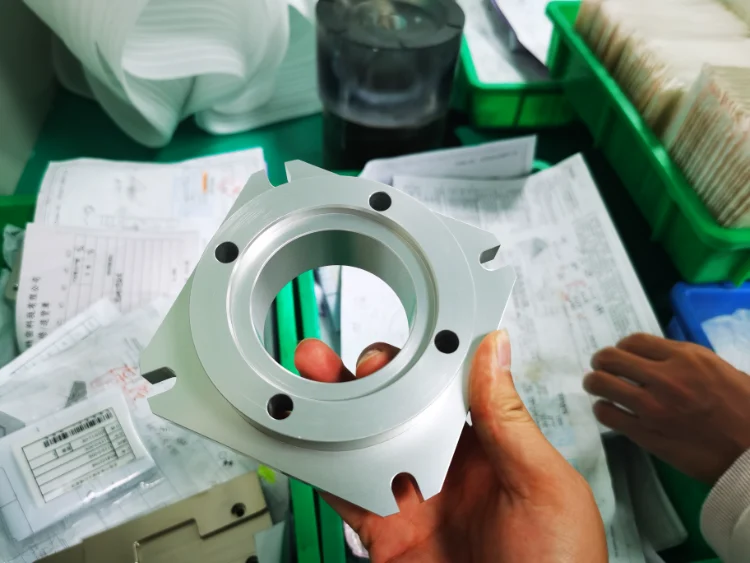

Custom CNC machining aluminium is widely chosen for its light weight, machinability, and corrosion resistance. Common alloys like 6061 and 7075 balance ease of machining with structural strength.

Advantages of CNC machining aluminium part:

- Fast material removal rates.

- Excellent surface finish after milling.

- Good strength-to-weight ratio for frames and housings.

- Anodizing options for wear and aesthetics.

If your design demands lightweight strength and good thermal properties, CNC machining aluminium is often the best option.

Understanding Custom CNC Machining Cost

Several factors determine custom machining cost:

- Material choice (aluminium vs. stainless steel vs. plastics).

- Part complexity and geometry.

- Tolerance tightness and surface finish.

- Quantity and batch size.

- Secondary processes (heat treatment, plating).

Small prototype runs have higher per-part CNC machining cost because setup time and CAM programming are amortized over fewer units. Larger batches reduce unit cost.

How to Lower Custom CNC Machining Cost

Design smarter to reduce CNC machining cost:

- Simplify geometry and avoid deep pocketing.

- Use standard tool sizes and fillets rather than sharp internal corners.

- Relax non-critical tolerances.

- Increase lot size when possible.

- Consolidate parts to reduce assembly steps.

A good CNC machining services partner will suggest design changes that lower cost without sacrificing function.

Choosing a Custom CNC Machining Services Partner

When evaluating vendors, consider:

- Machine capacity: Do they operate modern multi-axis centers?

- Material expertise: Can they handle aluminium, steels, titanium?

- Inspection & certifications: ISO, AS9100, or medical standards as needed.

- Communication: Fast quotes, DFM feedback, and clear lead times.

- Traceability: Batch records and material certificates.

A responsive custom machining services supplier shortens development cycles and prevents costly rework.

H2: Custom CNC Machining UK — Regional Strengths and Options

If you’re sourcing in Europe, custom CNC machining UK vendors offer strong engineering support and quick delivery across the continent. UK suppliers often combine:

- Tight manufacturing standards.

- Proximity to automotive and aerospace hubs.

- Strong value in engineering consultancy and prototype work.

For international firms, balancing cost and lead time by choosing CNC machining UK partners can be advantageous for European distribution.

Materials and Finishes for Custom CNC Machining Parts

Materials commonly used in CNC machining:

- Aluminium (lightweight, machinable).

- Stainless steel (corrosion-resistant, durable).

- Brass & copper (electrical and assembly uses).

- Titanium (high strength, light weight).

- Engineering plastics (POM, Nylon, PEEK) for insulation or low friction.

Finishes include anodizing, plating, bead blasting, polishing, and passivation to meet functional or aesthetic needs.

Quality Control in CNC Machining

Quality is non-negotiable. Reliable providers employ:

- First Article Inspection (FAI).

- Coordinate Measuring Machines (CMM).

- Statistical process control for volume runs.

- Material certificates and traceability.

Strong QC procedures ensure your custom CNC parts meet specifications consistently.

Prototyping vs Production — When to Use Custom CNC Machining

Use custom CNC machining for:

- Functional prototypes that must mimic production parts.

- Low-volume production runs where tooling cost of alternatives is prohibitive.

- Parts requiring tight tolerances or specific finishes.

For very high volumes, transitioning from custom CNC machining to dedicated tooling may reduce cost per piece.

Final Checklist Before Ordering Custom CNC Machining

- Confirm material and alloy.

- Specify critical tolerances and surface finish.

- Provide clear CAD/STEP files and notes.

- Ask for a sample or first article.

- Request inspection reports and certificates.

Following this checklist helps suppliers quote accurate CNC machining cost and deliver parts on spec.

Conclusion & Next Steps

Custom CNC machining offers precision, flexibility, and fast turnaround for prototypes and production parts. Whether you need custom CNC aluminium work, comprehensive CNC machining services, or a reliable CNC machining supplier, choosing the right partner makes all the difference.

If you’d like a tailored quote, DFM review, or lead-time estimate, contact Weldo Machining. Our team provides transparent pricing, engineering support, and full inspection documentation to ensure your project succeeds.