Working with a reliable custom cnc machining china factory allows global manufacturers to balance precision, scalability, and cost efficiency while maintaining strict quality and confidentiality standards.

Understanding a Custom CNC Machining China Factory

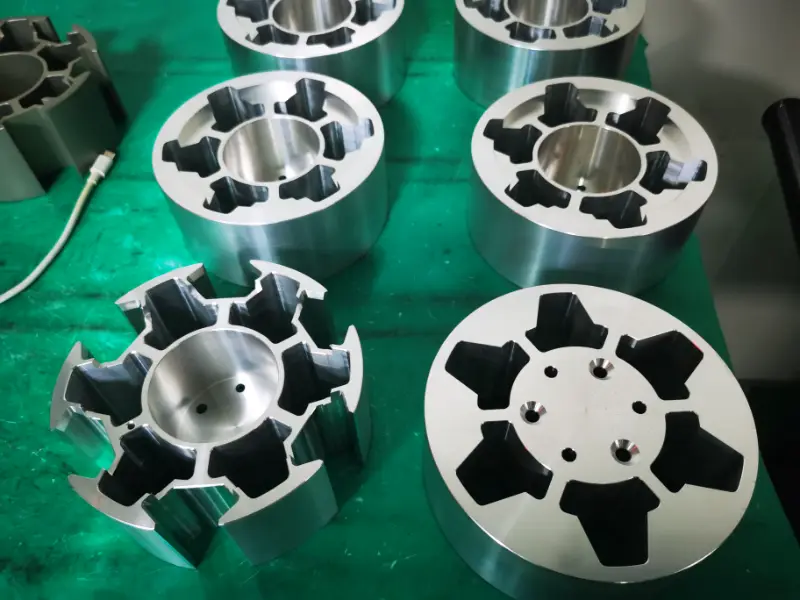

A custom cnc machining china factory is a specialized manufacturing company that provides precision CNC milling, turning, and multi-axis machining services tailored to customer drawings and specifications. Unlike standard job shops, a custom cnc machining china factory focuses on long-term OEM cooperation, repeatable quality, and international export requirements.

As a manufacturing partner, a custom cnc machining china factory supports custom parts production across multiple industries, including automotive, medical, industrial equipment, electronics, and energy.

Why Global Buyers Choose a Custom CNC Machining China Factory

Manufacturing Capability and Cost Structure

A custom cnc machining china factory combines advanced CNC equipment with a mature supply chain, enabling competitive pricing without sacrificing accuracy. Lower labor costs, centralized material sourcing, and efficient production planning contribute to sustainable cost advantages.

Scalability for OEM Projects

Many OEMs choose a custom cnc machining china factory because it can scale from prototype to mass production without changing suppliers. This continuity reduces quality risks and shortens production cycles.

Core Services Offered by a Custom CNC Machining China Factory

Precision CNC Milling and Turning Services

A professional custom cnc machining china factory provides CNC milling and CNC turning for complex geometries, tight tolerances, and functional surfaces. These processes support both structural and high-precision components.

Multi-Axis CNC Machining for Complex Parts

Advanced 4-axis and 5-axis machining capabilities allow a custom cnc machining china factory to reduce setups, improve accuracy, and consolidate parts, which is critical for high-end OEM applications.

Basic Requirements of a Professional CNC Machining Service Provider

Manufacturing and Engineering Capability

A qualified custom cnc machining china factory must demonstrate:

- Modern CNC machines

- Skilled engineers and operators

- CAD/CAM programming capability

- Stable process control

Without these fundamentals, consistent quality cannot be achieved.

Quality Management Systems

International buyers expect a custom cnc machining china factory to operate under documented quality systems. Standard requirements include:

- Incoming material inspection

- In-process control

- Final inspection reports

- Traceability records

Common Cooperation Issues With CNC Machining Factories

Communication Gaps and Drawing Interpretation

One frequent issue when working with a custom cnc machining china factory is misinterpretation of drawings or specifications. Differences in standards and terminology can lead to production errors.

Prevention strategy:

- Provide clear GD&T

- Confirm critical dimensions

- Conduct technical clarification before production

Lead Time and Delivery Delays

Lead time inconsistency can affect supply chains. A reliable custom cnc machining china factory mitigates this risk through production planning and capacity management.

Prevention strategy:

- Confirm production schedule in writing

- Use pilot orders to validate timelines

- Establish buffer inventory for repeat parts

Quality Inconsistency Between Batches

Inconsistent quality across batches is a common concern. A professional custom cnc machining china factory addresses this through standardized setups and inspection plans.

Prevention strategy:

- Require First Article Inspection (FAI)

- Lock process parameters after approval

- Request batch inspection reports

The Importance of NDA When Working With a China CNC Factory

Protecting Intellectual Property

Signing a Non-Disclosure Agreement (NDA) is essential when cooperating with a custom cnc machining china factory. CNC parts often involve proprietary designs, tolerances, and functional features.

An NDA ensures:

- Design confidentiality

- Restricted data sharing

- Legal protection against unauthorized use

Building Trust and Long-Term Cooperation

A reputable custom cnc machining china factory will readily sign an NDA and follow internal data protection procedures. This demonstrates professionalism and commitment to long-term partnership.

Materials Commonly Used by a Custom CNC Machining China Factory

Metal Materials

Most custom cnc machining china factory projects involve:

- Aluminum alloys

- Stainless steel

- Carbon and alloy steel

- Brass and copper

These materials support structural strength, corrosion resistance, and thermal stability.

Engineering Plastics

Plastic CNC machining is also widely supported by a custom cnc machining china factory, including:

China’s CNC Machining Industry Landscape

China has thousands of CNC machining suppliers, but only a limited number meet international OEM standards. Selecting the right custom cnc machining china factory requires careful evaluation of experience, quality systems, and export capability.

Top 12 leading CNC Machining Companies in China

(Based on Google Visibility & Industry References)

1. RapidDirect

- Location: Shenzhen, Guangdong

- Founded: 2009

RapidDirect is widely recognized as a digital-first CNC machining service provider in China. The company focuses on CNC milling, turning, and rapid manufacturing for international OEM customers, particularly in product development and low-to-medium volume production.

2. WayKen Rapid Manufacturing

- Location: Shenzhen, Guangdong

- Founded: 2003

WayKen is one of the earliest CNC machining and rapid manufacturing companies in China with strong global exposure. It is frequently referenced for 5-axis CNC machining, prototyping, and bridge production services.

3. TiRapid

- Location: Shenzhen, Guangdong

- Founded: 2010

TiRapid is known for precision CNC machining and rapid prototyping. It serves automotive, industrial, and engineering clients, with emphasis on surface finishing and complex part geometry.

4. Star Rapid

- Location: Zhongshan, Guangdong

- Founded: 2005

Star Rapid combines CNC machining with other manufacturing processes such as injection molding and vacuum casting. The company is well-known among overseas buyers seeking integrated manufacturing solutions.

5. Yijin Hardware

- Location: Shenzhen, Guangdong

- Founded: 2003

Yijin Hardware operates large-scale CNC machining facilities and supports a wide range of materials. It is often cited in industry rankings for its equipment capacity and stable production capability.

6. DEK Manufacturing

- Location: Shenzhen, Guangdong

- Founded: 2002

DEK Manufacturing focuses on high-precision CNC machining, including multi-axis machining and tight-tolerance parts. It serves aerospace, medical, and industrial equipment sectors.

7. AT Machining

- Location: Shenzhen, Guangdong

- Founded: 2007

AT Machining is a flexible CNC machining supplier supporting custom parts across various industries. It is often referenced for its adaptability in both prototyping and production machining.

8. Gensun Precision

- Location: Shenzhen, Guangdong

- Founded: 2006

Gensun Precision provides CNC machining and metal fabrication services with export experience. The company emphasizes quality management and consistency for overseas customers.

9. 3ERP

- Location: Zhongshan, Guangdong

- Founded: 2010

3ERP is known for rapid CNC machining and prototyping services. It is commonly referenced by startups and engineering teams requiring fast turnaround and technical support.

10. Runsom Precision

- Location: Shenzhen, Guangdong

- Founded: 2010

Runsom Precision combines CNC machining with plastic manufacturing processes. It is frequently listed as a multi-process supplier suitable for OEM sourcing.

11. Junying CNC Machining

- Location: Shenzhen, Guangdong

- Founded: 2005

Junying specializes in precision CNC machining and custom metal parts. The company supports complex geometries and engineering-driven projects.

12. Weldo Machining

- Location: Dongguan, Guangdong

- Founded: 2012

Weldo Machining is a specialized custom cnc machining china factory serving international OEM clients. The company focuses on precision CNC machining, NDA compliance, and long-term cooperation for custom parts manufacturing.

Strategic Comparison Considerations

When choosing from this list of top China CNC machining suppliers:

| Criterion | What to Evaluate |

|---|---|

| Precision Capability | 3-, 4-, 5-axis machining |

| Quality Systems | ISO certification, inspection reports |

| Volume Support | Prototype vs. production runs |

| NDA / IP Protection | Confidentiality commitment |

| Communication | Project tracking & language support |

Future Trends in Custom CNC Machining in China

Automation, digital inspection, and process standardization continue to elevate the capabilities of the custom cnc machining china factory. These advancements enable higher precision, faster turnaround, and improved consistency for global customers.

Partner With Weldo Machining as Your Custom CNC Machining China Factory

If you are looking for a dependable custom cnc machining china factory that combines precision manufacturing, strict quality control, and strong confidentiality practices, Weldo Machining is your trusted partner.

Contact Weldo Machining today to discuss your project requirements, sign an NDA, and receive a competitive quotation tailored to your CNC machining needs.