DFM (Design for Manufacturability) refers to the practice of designing products that are easy and cost-effective to manufacture. When applied to various manufacturing processes, DFM ensures that the product design aligns with the manufacturing capabilities to reduce costs, optimize material usage, and improve overall product quality. In this article, we’ll dive into the DFM meaning, how it relates to different manufacturing processes, and the key factors that make a design manufacturable.

What is DFM Meaning?

DFM (Design for Manufacturability) is a methodology that aims to design products that can be efficiently and cost-effectively produced. The goal is to simplify the design, reduce manufacturing complexity, and eliminate potential issues before the production process begins. Whether it’s CNC machining, aluminium extrusion, or injection molding, DFM analysis helps ensure that parts are easy to manufacture, reducing time-to-market and minimizing errors in the final product.

Why DFM is Crucial Before Mass Production

1. Reduces Production Costs

DFM helps identify and eliminate unnecessary complexities in the design, such as intricate features or complex geometries that drive up costs. Simplifying the design can reduce material waste, tooling complexity, and production time, ultimately lowering the overall manufacturing costs.

2. Improves Production Efficiency

By considering manufacturability early, DFM ensures that the design fits within the capabilities of the manufacturing process. This reduces the need for custom tooling, complicated setups, and lengthy production cycles, making the entire process more efficient.

3. Identifies Potential Issues Early

DFM allows manufacturers to identify design flaws and potential issues before mass production starts. For example, issues like material waste, part distortion, or difficulty in assembly can be addressed early, avoiding delays and costly rework during production.

4. Enhances Product Quality

By simplifying designs and optimizing materials and assembly methods, DFM ensures that products meet high-quality standards. This leads to fewer defects, better durability, and more reliable parts, which is critical for customer satisfaction.

5. Shortens Development Time

With DFM, the time required to move from design to production is shortened. Early identification and resolution of manufacturing challenges prevent delays, speeding up the overall development process.

6. Optimizes Supply Chain Management

DFM also aids in supply chain optimization by standardizing parts and materials, reducing the risk of shortages, and improving forecasting. Simplified designs also make it easier to manage inventory and improve overall production scheduling.

How DFM Relates to Different Manufacturing Processes

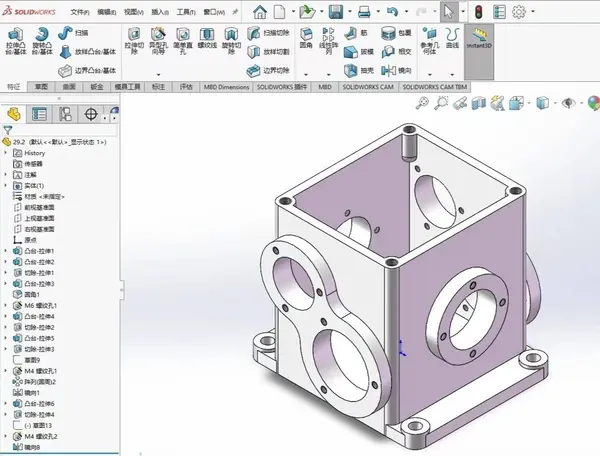

DFM and CNC Machining

CNC machining is a precise process used to create parts from raw materials like aluminium, steel, or plastic. DFM for CNC machining focuses on designing parts that are easy to machine, which includes:

- Minimizing cutting time by simplifying geometries.

- Reducing tool wear by avoiding deep pockets and intricate holes.

- Efficient material usage by optimizing part orientation.

CNC machining is ideal for producing high-precision parts with tight tolerances, making it suitable for small batches, prototyping, and parts requiring intricate designs.

DFM and Aluminium Extrusion

Aluminium extrusion is the process of pushing aluminium through a mold to create parts with consistent cross-sectional profiles. When designing for aluminium extrusion, DFM principles focus on:

- Simple, straight profiles that are easy to extrude without defects.

- Avoiding sharp corners or deep features that would require complex dies.

- Consistent wall thickness to avoid issues during extrusion and cooling.

Extruded aluminium is commonly used for structural applications like frames, beams, and heat sinks.

DFM and Sheet Metal Fabrication

In sheet metal fabrication, parts are made by cutting, bending, and stamping metal sheets. DFM for sheet metal fabrication involves:

- Simplifying bends and reducing tooling complexity.

- Optimizing flat patterns to minimize material waste.

- Avoiding tight radii and deep draws that complicate the fabrication process.

Sheet metal is used for enclosures, panels, and brackets in industries like electronics and automotive.

DFM and Injection Molding

Injection molding involves injecting molten material (usually plastics) into a mold to form a part. For injection molding, DFM ensures:

- Uniform wall thickness to ensure even cooling and prevent defects.

- Avoiding undercuts and other complex features that increase mold complexity.

- Proper draft angles and gating design for easy part release.

Injection molded parts are ideal for high-volume production, such as containers, covers, and automotive parts.

DFM and Composite Injection Molding

Composite injection molding uses reinforcement materials like fiberglass or carbon fiber to create stronger parts. DFM for composite molding focuses on:

- Strategically placing reinforcement fibers to enhance strength without disrupting the molding process.

- Designing balanced parts to avoid distortion during curing.

- Understanding material behavior to ensure smooth molding.

This process is widely used in industries requiring lightweight, high-strength parts, such as aerospace and automotive.

DFM and 3D Printing

3D printing (or additive manufacturing) builds parts layer by layer from a digital design. For 3D printing, DFM encourages:

- Leveraging the benefits of additive manufacturing, such as complex internal structures and organic shapes.

- Avoiding overhangs or unnecessary supports, which can increase material use and post-processing time.

- Considering material properties to ensure the part meets strength, flexibility, and finish requirements.

3D printing is ideal for rapid prototyping, low-volume production, and parts with complex geometries that are challenging for traditional methods.

How These Processes Interconnect Through DFM

Optimized Design for Multiple Manufacturing Methods

DFM ensures that a design can be easily adapted to various manufacturing methods. For example, a part designed for CNC machining can also be adapted for aluminium extrusion or sheet metal fabrication if it’s designed with simplicity in mind.

Selecting the Right Process Based on Design Complexity

For complex parts, CNC machining or 3D printing is often the preferred method due to their ability to handle intricate designs. However, for simpler, high-volume parts, injection molding or aluminium extrusion may be more cost-effective and efficient.

Reducing Costs with Hybrid Approaches

Combining multiple processes can reduce costs and improve production efficiency. For example, aluminium extrusion can create basic shapes, while CNC machining can be used for precision finishing. Similarly, injection molding can be used for high-volume production, while 3D printing is ideal for prototyping and iterative designs.

Material Selection Across Processes

DFM principles also guide the selection of the most suitable material for each process. For example, aluminium is commonly used in CNC machining and extrusion, while plastics and composites are often better suited for injection molding and 3D printing. The right material selection ensures optimal performance, cost-efficiency, and manufacturability.

Advantages of DFM (Design for Manufacturability)

Cost Reduction

DFM helps identify ways to simplify designs, reduce material waste, and minimize tooling costs, leading to significant savings in production costs.

Improved Product Quality

By addressing manufacturability early, DFM reduces defects, ensures consistent part performance, and meets quality standards more effectively.

Faster Time-to-Market

DFM accelerates the design-to-production process by identifying issues early, reducing redesigns, and enabling quicker transitions to mass production.

Simplified Manufacturing

DFM promotes simpler designs that align with manufacturing capabilities, reducing complexity and the need for specialized tools, improving efficiency.

Minimized Risk of Manufacturing Failures

Identifying potential issues early, such as material incompatibility or assembly difficulties, reduces the risk of delays, defects, and costly rework.

Optimized Resource Usage

DFM leads to better resource management, reducing material waste and improving labor and machine efficiency.

Easier Assembly and Lower Labor Costs

By simplifying assembly processes, DFM reduces manual steps, lowers labor costs, and improves overall production speed.

Better Communication

DFM encourages collaboration between design and manufacturing teams, ensuring the product design fits the manufacturing process and avoiding miscommunication.

Scalability

DFM ensures designs can be efficiently scaled for both small batches and mass production, making it easier to manage both prototypes and large volumes.

Choosing the Right Manufacturer for Your DFM Needs

Selecting the right DFM design and DFM manufacturing provider is critical to ensuring a product is manufacturable, cost-effective, and of high quality. At Weldo Machining, we specialize in working with CNC machining, aluminium extrusion, and other manufacturing processes. We help clients make the best DFM design choices to reduce costs and ensure fast, reliable production.

Contact us today for a customized quote and learn more about how Weldo Machining can optimize your project with DFM principles.

FAQ of DFM meaning

What does DFM mean in manufacturing?

DFM (Design for Manufacturability) refers to the process of designing products that are easy and cost-effective to manufacture, considering various manufacturing methods.

How does DFM help in reducing manufacturing costs?

DFM minimizes complexity in the design, optimizes material usage, reduces rework, and selects the best manufacturing methods, leading to lower production costs.

Which manufacturing processes are considered in DFM?

DFM can be applied to various manufacturing processes such as CNC machining, aluminium extrusion, injection molding, sheet metal fabrication, and 3D printing.

How can I apply DFM to my product design?

By simplifying part geometries, choosing the right materials, and considering assembly and manufacturing methods early in the design phase, you can apply DFM principles effectively.