A qualified high precision CNC machining manufacturer plays a critical role in industries where micron-level accuracy, repeatability, and process stability are mandatory. From aerospace and medical devices to semiconductor and optical systems, high precision CNC machining manufacturers are expected to deliver consistent quality under extremely tight tolerance requirements. This article explains what defines high precision machining, how it differs from ultra-precision machining, what equipment and processes are required, and how to select the right manufacturing partner.

What Is a High Precision CNC Machining Manufacturer

A high precision CNC machining manufacturer is a specialized machining company capable of producing parts with very tight tolerances, high dimensional accuracy, and stable repeatability across multiple production batches. Unlike general CNC shops, these manufacturers operate under stricter process control, inspection standards, and environmental management.

Key characteristics include:

- Advanced CNC equipment with high positional accuracy

- Controlled machining environments

- Comprehensive inspection and metrology capability

- Experienced process and quality engineering teams

A true high precision CNC machining manufacturer focuses on system-level accuracy, not just individual machines.

High Precision CNC Machining vs Ultra-Precision Machining

Understanding tolerance levels helps clarify manufacturing capability.

High Precision CNC Machining

High precision CNC machining typically achieves:

- Tolerances of ±0.01 mm to ±0.005 mm

- Surface roughness down to Ra 0.8–0.4 μm

- Stable repeatability for production parts

Most aerospace, medical, semiconductor, and automation components fall into this category.

Ultra-Precision Machining

Ultra-precision machining pushes beyond conventional CNC limits:

- Tolerances of ±0.002 mm or tighter

- Surface finishes below Ra 0.1 μm

- Often requires diamond tools and specialized machines

While not every high precision CNC machining manufacturer offers ultra-precision capability, understanding the distinction is essential when defining requirements.

Tolerance and Accuracy Standards in High Precision CNC Machining

Tolerance is the foundation of high precision machining.

Common Precision Grades

- ±0.05 mm: General CNC machining

- ±0.02 mm: Precision machining

- ±0.01 mm: High precision CNC machining

- ±0.005 mm and below: Advanced / ultra-precision

A reliable high precision CNC machining manufacturer must maintain not only single-part accuracy but also batch-to-batch consistency.

Equipment Requirements for a High Precision CNC Machining Manufacturer

Equipment capability defines achievable precision.

CNC Machines and Platforms

A professional high precision CNC machining manufacturer typically operates:

- High-end 3-axis and 5-axis machining centers

- Machines with thermal compensation and high-resolution encoders

- Rigid machine structures to minimize vibration

Machine stability is often more important than spindle speed alone.

Tooling and Fixturing Systems

Precision machining depends heavily on:

- High-quality cutting tools

- Precision tool holders and collets

- Custom fixtures with minimal deformation

Poor fixturing can compromise even the most accurate machines.

Common Machining Processes Used in High Precision CNC Manufacturing

A high precision CNC machining manufacturer combines multiple processes to achieve final accuracy.

CNC Milling and Turning

Precision milling and turning are the foundation for most high-accuracy components, especially when combined with optimized toolpaths and multi-axis positioning.

5-Axis CNC Machining

5-axis machining reduces setup errors and improves geometric accuracy by machining multiple surfaces in a single setup, making it essential for complex high precision parts.

Grinding and Secondary Precision Processes

Some high precision CNC machining manufacturers integrate:

- Surface grinding

- Cylindrical grinding

- Honing or lapping

These processes refine tolerances beyond standard cutting capability.

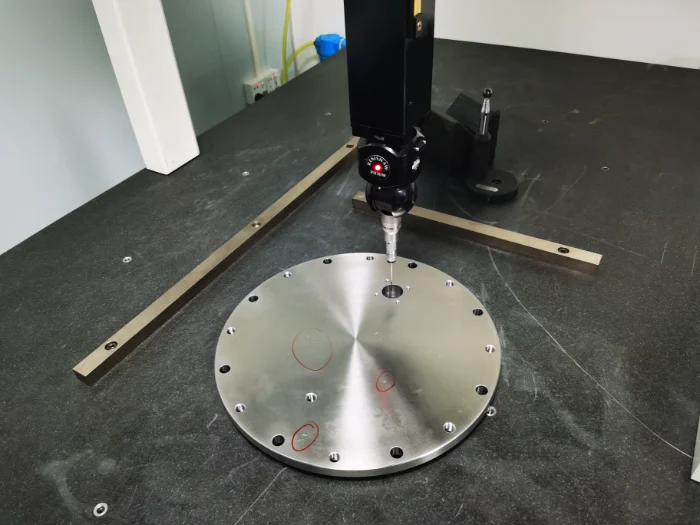

Inspection and Measurement Tools in High Precision CNC Machining

Inspection capability is as important as machining equipment.

A qualified high precision CNC machining manufacturer uses:

- Coordinate Measuring Machines (CMM)

- Optical measurement systems

- Surface roughness testers

- In-process probing systems

Measurement data ensures accuracy and traceability throughout production.

Daily Production Controls in a High Precision CNC Machining Workshop

Precision is maintained through disciplined shop-floor management.

Key production controls include:

- Temperature and humidity control

- Tool life monitoring and replacement schedules

- First article inspection (FAI)

- Process documentation and revision control

Without daily process control, long-term precision cannot be sustained.

Materials Used by High Precision CNC Machining Manufacturers

Material behavior directly affects machining accuracy.

Common Precision Machining Materials

- Aluminum alloys (6061, 7075, 7050) – stable and lightweight

- Stainless steels (304, 316, 17-4PH) – strength and corrosion resistance

- Alloy and tool steels – wear resistance and rigidity

- Brass and copper alloys – conductivity and machinability

These materials are widely used for high precision CNC machining parts.

Special and Advanced Materials

Many high precision CNC machining manufacturers also work with:

- Titanium alloys – aerospace and medical applications

- Inconel and superalloys – high-temperature environments

- PEEK, PTFE, and engineering plastics – insulation and chemical resistance

Advanced materials require slower machining speeds and stricter process control.

Surface Finishing Options for High Precision CNC Machining Parts

Surface treatment affects both function and dimensional stability.

Common Surface Finishes

- Anodizing (Type II / Type III)

- Passivation

- Electropolishing

- Precision polishing

- Plating (nickel, hard chrome)

A capable high precision CNC machining manufacturer understands how surface treatment impacts final tolerances.

Cost Structure of High Precision CNC Machining Manufacturing

Pricing reflects precision requirements.

Typical Cost Ranges (Reference)

- Standard high precision parts: USD 100–300 per piece

- Complex high precision components: USD 300–800 per piece

- Ultra-tight tolerance parts: USD 800–1,500+ per piece

Inspection, setup, and process control account for a large portion of total cost.

Key Factors Affecting High Precision CNC Machining Cost

Major cost drivers include:

- Tolerance and accuracy requirements

- Material type and machinability

- Part geometry and feature density

- Inspection depth and documentation

- Production volume and repeatability

Understanding these factors helps avoid unrealistic cost expectations.

How to Choose a High Precision CNC Machining Manufacturer

Selecting the right supplier is critical for long-term success.

Key evaluation criteria:

- Proven experience in high precision CNC machining

- Advanced inspection and metrology capability

- Stable quality management systems

- Engineering and DFM support

- Transparent communication and documentation

A qualified high precision CNC machining manufacturer reduces risk and improves consistency.

Long-Term Value of the Right Precision Manufacturing Partner

A strong partnership offers:

- Consistent quality across product lifecycles

- Reduced rework and scrap

- Predictable delivery and cost control

- Support for future design upgrades

Precision manufacturing is a long-term collaboration, not a one-time transaction.

Final Thoughts on High Precision CNC Machining Manufacturers

A high precision CNC machining manufacturer must deliver more than tight tolerances—it must provide stable processes, advanced inspection, and disciplined production control. By understanding tolerance requirements, equipment capability, materials, and cost drivers, buyers can make informed sourcing decisions.

If you are looking for a reliable high precision CNC machining manufacturer with advanced equipment, strict quality control, and proven experience, Weldo Machining provides professional high precision CNC machining solutions for demanding applications. Contact Weldo Machining today to discuss your project requirements and receive a detailed quotation.