As heavy industry continues to grow, demand for large part cnc turning is rising across sectors such as heavy equipment, new energy, aerospace, and rail transit. Compared with standard turning, large-part turning differs significantly in size, weight, material rigidity, fixturing requirements, dimensional standards, inspection, and packaging/transport logistics.

What Is Large Part CNC Turning

Large Part CNC Turning refers to automated cutting of large-diameter, long-length, or ultra-heavy rotational parts (such as large shafts, rollers, and flanges) using heavy-duty CNC lathes equipped with high-rigidity structures, long travels, and high-load chucks. Typical operations include OD/ID machining, facing, taper turning, and threading.

Key Differences Between Large-Part Turning and Conventional Turning

Machine scale and rigidity

- Conventional turning: Uses small-to-medium lathes with moderate bed rigidity and higher spindle speeds, mainly for standard-size turned parts.

- Large-part turning: Requires heavy/ultra-heavy CNC lathes with wider, thicker beds and larger guideway spacing, delivering high rigidity and vibration resistance to withstand centrifugal forces from large workpieces and heavy cutting loads.

Workpiece size and fixturing

- Conventional turning: Typical diameters are under 500 mm; parts are shorter and lighter, commonly clamped directly with a 3-jaw chuck.

- Large-part turning: Diameters can reach several meters (or more), and parts can weigh multiple tons. Center rests, follower rests, or dedicated fixtures are often required for support, with more low-speed, heavy-load cutting.

Process challenges and accuracy control

- Conventional turning: Focuses mainly on dimensional tolerances and surface finish; thermal deformation effects are relatively limited.

- Large-part turning: In addition to size accuracy, it must overcome self-weight deformation, thermal growth, and dynamic balance issues, with high requirements on tool life and chip evacuation efficiency.

What Operations and Part Features Can Large-Part CNC Turning Handle

Large-part CNC turning targets rotational geometries. Key operations and achievable features include:

Core operations

- OD turning & facing: Remove stock allowance and create basic cylindrical surfaces and end faces.

- ID boring: Machine deep holes, through holes, or blind holes.

- Tapers & chamfers: Produce conical surfaces and edge chamfers.

- Thread cutting: Metric, inch, module, or face threads.

- Grooving & cutoff: Ring grooves, oil grooves, or parting-off.

- Form turning: Arcs or special curved profiles.

Typical part features

- Shaft features: Stepped shafts, long shafts, eccentric shafts.

- Disc features: Large flanges, hubs, flywheels.

- Hole features: Deep holes, stepped bores, internal threaded holes.

- Surface features: External threads, knurling, relief grooves, sealing grooves (e.g., O-ring grooves).

- Special geometry: Tapers, spherical surfaces, eccentric circles.

Machinable Materials and Selection Recommendations

Material selection for large-part CNC turning must balance machinability, structural strength, and cost control.

Common materials

Alloy steel and stainless steel

- 4140/4340 alloy steel: Commonly used; high strength and good impact toughness—suitable for heavy-duty shafts and gears.

- 304/316 stainless steel: Corrosion-resistant, often used in chemical equipment; prone to work hardening and requires higher tool performance.

Carbon steel

- 1045 carbon steel: Cost-effective, medium strength, easy to turn and heat treat; suitable for general mechanical parts.

Non-ferrous metals

- 6061/7075 aluminum: Excellent machinability and fast chip evacuation; suitable for large structural parts sensitive to weight.

- Bronze/brass: Wear- and corrosion-resistant; often used for large marine propellers or wear sleeves/bushings.

Specialty materials

- Titanium (Ti-6Al-4V): High strength-to-weight ratio but poor thermal conductivity; difficult to machine, mainly for critical aerospace parts.

- High-temperature alloys (e.g., Inconel): High heat resistance for energy equipment; high cutting resistance and difficult machining.

Material selection tips

- Prioritize free-machining grades when feasible: For large parts, choosing free-machining steels (e.g., 1215) or alloys with sulfur/lead additions—while meeting mechanical requirements—can significantly reduce machining time and cost.

Blank selection for large-part turning

- Forgings: Suitable for heavy-load shafts; dense internal structure.

- Castings: Suitable for complex large housings or hubs; can reduce machining allowance.

- Thick-wall tube/bar stock: Suitable for simple rotational parts; material utilization is relatively low.

Heat treatment timing

For large parts, heat treatment (quench & temper / annealing) is recommended after roughing and before finishing to relieve internal stress and prevent distortion from stress release after finishing.

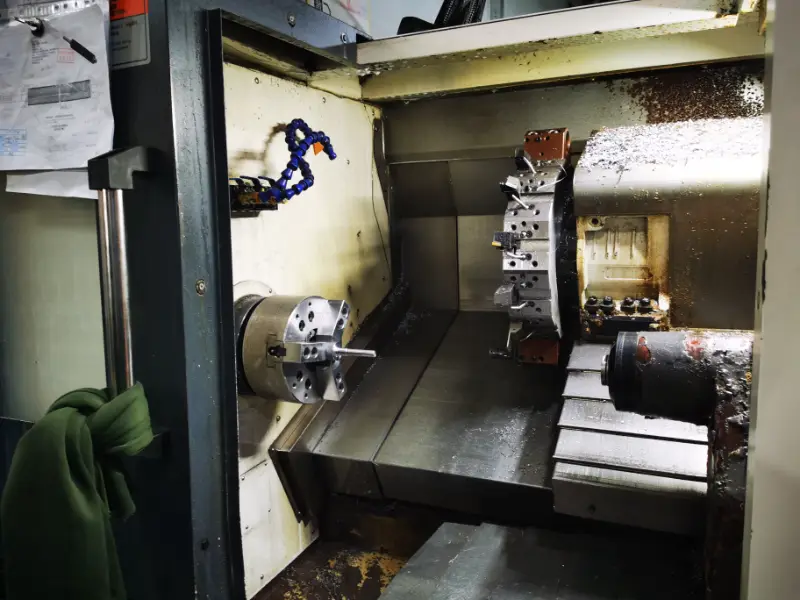

Equipment Capability and Machining Range

Large-part CNC turning equipment (heavy/ultra-heavy CNC lathes) typically exceeds standard machines in travel, load capacity, and heavy cutting capability.

Machining range

- Swing diameter: Typically 800–2000 mm; some ultra-heavy machines exceed 3000 mm.

- Machining length (between centers): Commonly 1000–3000 mm; long shafts can extend to 5 m or more.

- Chuck clamping diameter: Typically 300–1200 mm; with face drive and tailstock support, larger shaft blanks can be accommodated.

Load capacity

- Max load between centers: Typically 0.5–5 tons; ultra-heavy machines can handle 5–10 tons.

- Chuck size: Large hydraulic chucks (e.g., 15″, 21″, 25″+) providing clamping forces in the thousands of newtons.

Dynamic and cutting capability

- Spindle speed range: Limited by centrifugal force on large diameters; max speed typically 500–1200 rpm, but with very high torque (thousands of N·m) at low speed for heavy roughing.

Accuracy, Tolerances, and Surface Quality Control

Large-part turning is strongly affected by “scale effects.” The core challenge is controlling gravitational deformation and thermal growth, making geometric tolerances significantly harder to maintain.

Typical tolerance capability

- Linear dimensions: Standard ±0.05 to ±0.1 mm; precision (with temperature control + high rigidity) ±0.01 to ±0.02 mm; long shafts often follow IT7–IT8 or length-proportional control.

- Geometric tolerances: Roundness/cylindricity 0.005–0.02 mm; coaxiality for long shafts φ0.02–φ0.05 mm; flange face flatness 0.02–0.05 mm (within 1 m diameter).

Surface quality control

- Roughness: Finish turning Ra 1.6–3.2 μm; super-finishing/polishing Ra 0.4–0.8 μm.

- Defect control: Use damped toolholders or follower rests to suppress chatter marks; optimize cutting parameters and coolant to prevent built-up edge and protect surface finish.

Key techniques for accuracy control

- Thermal compensation: CNC systems compensate for spindle/bed thermal deformation in real time.

- Auxiliary support: Hydraulic center rests/follower rests offset sag from the self-weight of slender shafts.

- In-process probing: High-precision probes (e.g., Renishaw) enable in-cycle measurement and tool offset correction to reduce re-clamping error.

- Stress relief: Heat treat after roughing to prevent distortion or cracking after finishing.

Machining Challenges and Solutions

The main challenges in large-part CNC turning concentrate on deformation control, vibration suppression, chip evacuation, and thermal management.

Workpiece deformation and fixturing

- Challenge: Thin-wall parts deform under clamping; long shafts sag under self-weight and may spring back out of tolerance.

- Solutions: Use low-stress hydraulic/soft jaws to prevent distortion; use hydraulic center rests and follower rests to control deflection to microns; apply a “rough turn → heat treat → finish turn” process to release internal stress.

Vibration and surface finish

- Challenge: Long tool overhang or low workpiece rigidity can cause low-frequency vibration (chatter), leading to vibration marks or edge chipping.

- Solutions: Use high-rigidity or damped bars; use “large depth of cut, low feed” to avoid resonance; large disc parts require strict dynamic balancing.

Chip evacuation and cooling

- Challenge: Long, heavy chips can entangle and scratch surfaces; heat buildup drives thermal distortion.

- Solutions: Use 50–70 bar high-pressure, through-tool coolant for forced chip breaking and cooling; use dedicated chipbreaker inserts to produce C-shaped or short helical chips.

Measurement and alignment

- Challenge: Uneven stock makes alignment difficult; stopping for measurement introduces temperature error.

- Solutions: Use CNC auto-centering or probing to establish a compensated coordinate system; use in-machine probing after critical operations to auto-correct parameters for “one setup, conforming parts.”

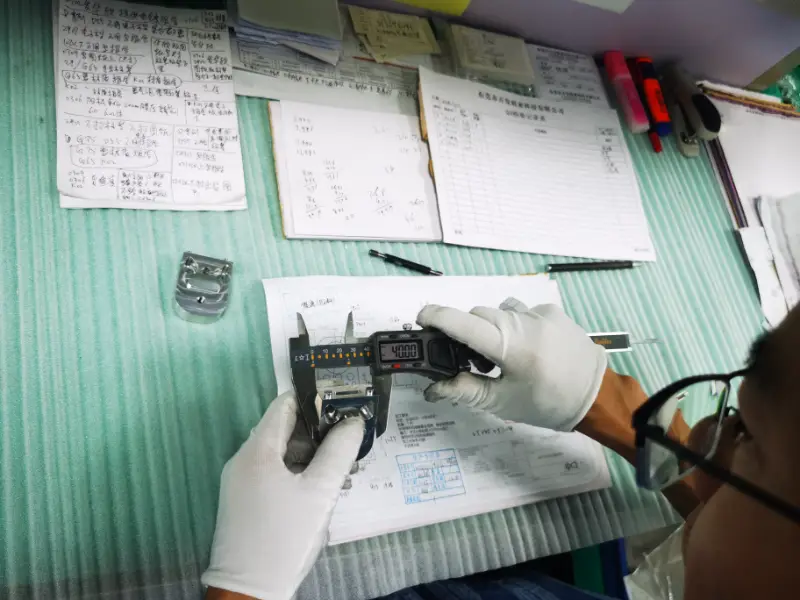

Quality Inspection and Delivery Assurance

- Inspection capability: Calipers, micrometers, bore gauges, roundness testers, and CMM for measurement and recording across features.

- Documents available: Raw material inspection reports, First Article Inspection (FAI), and more as required.

Typical Industries and Application Examples

- Energy & heavy industry: Pump shafts, couplings, flanges, housings.

- Aerospace: Large structural sleeves, load-bearing rotational parts.

- Automotive & equipment: Rollers, drive shafts, rotary tooling and fixture components.

- Medical devices: Large housings/support rotational assemblies (as applicable).

Cost and Quotation Factors

Large-part CNC turning cost is mainly influenced by material, part size, accuracy requirements, tolerance grade, special feature requirements, surface roughness, heat treatment and surface finishing, plus packaging requirements and freight cost.

Conclusion

If you would like more related information after reading this article, or want a fast quote for your part manufacturing, please contact us.