Low volume CNC machining is an efficient manufacturing solution for producing high-precision parts in small quantities. It is widely used for prototypes, pilot runs, customized components, and early-stage production where flexibility, speed, and cost control are critical.

What Is Low Volume CNC Machining

Low volume CNC machining refers to CNC production runs typically ranging from a few units to several hundred parts. Compared with mass production, small batch CNC machining avoids expensive tooling and allows rapid design iteration while maintaining production-level accuracy.

Key characteristics include:

- Small batch quantities

- Minimal tooling investment

- High design flexibility

- Short lead times

Low volume CNC machining is commonly used during product development and market validation stages.

Common Materials for Low Volume CNC Machining

Material selection is one of the most important factors affecting performance and cost in small batch CNC machining. Different materials influence machining time, unit price, and minimum order quantity.

Metal Materials

- Aluminum (6061, 7075)

The most popular choice for low volume CNC machining. Aluminum offers excellent machinability, low cost, and stable dimensional performance. - Stainless Steel (304, 316)

Provides high strength and corrosion resistance but increases machining time and cost due to material hardness. - Carbon Steel (1018, 1045)

A cost-effective option for structural parts where corrosion resistance is not critical. Often combined with surface coating. - Tool Steel (D2, H13, A2)

Used for wear-resistant parts, fixtures, and tooling components. Requires slower cutting speeds and specialized tooling. - Titanium (Ti-6Al-4V)

Selected for aerospace and medical applications. Titanium significantly increases low volume CNC machining cost due to long cycle times.

Engineering Plastics

- PEEK – High temperature and chemical resistance

- PTFE – Low friction and chemical stability

- POM (Delrin) – Dimensional stability and machinability

- Nylon (PA) – Cost-effective and tough

- ABS / PC – Used for housings and covers

Engineering plastics are widely used to reduce low volume CNC machining cost for non-load-bearing parts.

Material × Unit Price × MOQ Comparison (Low Volume CNC Machining)

| Material | Typical Unit Price (USD) | Common MOQ | Cost Level | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061 | 30–80 | 1–10 pcs | Low | Housings, brackets |

| Aluminum 7075 | 45–120 | 1–10 pcs | Medium | Structural parts |

| Stainless Steel 304 | 80–250 | 1–5 pcs | Medium–High | Precision components |

| Stainless Steel 316 | 120–350 | 1–5 pcs | High | Medical, chemical use |

| Carbon Steel 1045 | 60–180 | 1–10 pcs | Medium | Mechanical structures |

| Tool Steel (D2/H13) | 150–500 | 1–3 pcs | High | Fixtures, wear parts |

| Titanium Ti-6Al-4V | 250–800+ | 1–3 pcs | Very High | Aerospace, medical |

| PEEK | 120–400 | 1–5 pcs | High | Insulation, high-temp |

| PTFE | 80–250 | 1–5 pcs | Medium | Low-friction parts |

| Nylon (PA) | 40–120 | 1–10 pcs | Low–Medium | Covers, supports |

| ABS / PC | 30–90 | 1–10 pcs | Low | Enclosures |

Prices are reference ranges and vary based on geometry, tolerance, and surface finish.

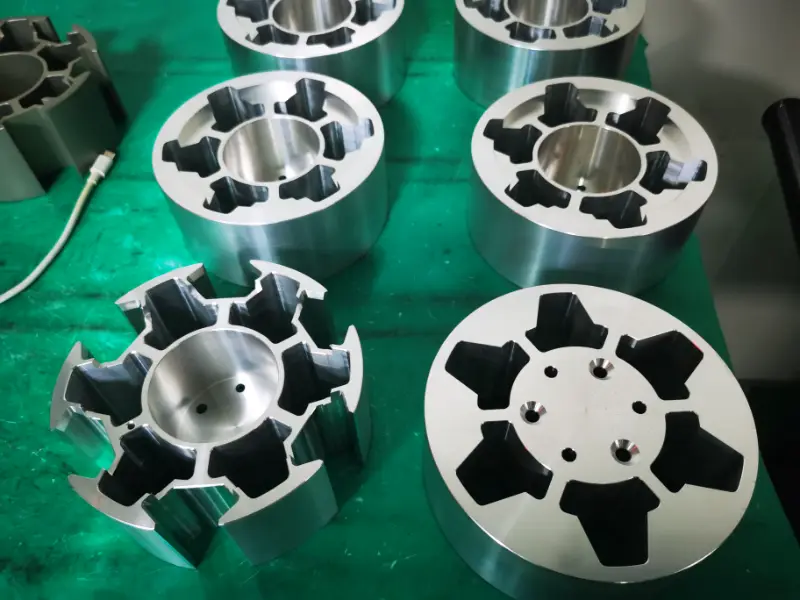

Typical Parts Produced by Low Volume CNC Machining

Low volume CNC machining supports a wide range of functional and structural components, including:

- Mechanical housings and enclosures

- Brackets, mounts, and frames

- Precision plates and fixtures

- Functional prototypes

- Customized end-use parts

These components often require production-grade accuracy despite small quantities.

Surface Finishing Options and Cost Ranges

Surface finishing improves durability, appearance, and functionality.

Common options include:

- Anodizing: USD 5–30 per part

- Powder coating: USD 15–40 per part

- Electropolishing: USD 20–60 per part

- Passivation: USD 10–40 per part

Surface treatments typically account for 10%–35% of total small batch CNC machining cost.

Tolerance Levels in Low Volume CNC Machining

Typical tolerance ranges include:

- ±0.10 mm – standard functional parts

- ±0.05 mm – precision mechanical parts

- ±0.02 mm or tighter – critical interfaces

Tighter tolerances increase machining time, inspection effort, and cost.

Key Factors Affecting Low Volume CNC Machining Cost

Major cost drivers include:

- Part geometry and feature complexity

- Material type and removal volume

- Tolerance and surface finish requirements

- Programming and setup time

- Order quantity and repeatability

In low volume CNC machining, setup and engineering time often represent a larger share of total cost.

How to Reduce Low Volume CNC Machining Cost

Effective cost-control strategies include:

- Avoiding unnecessary tight tolerances

- Selecting cost-efficient materials

- Standardizing surface finishes

- Slightly increasing batch size

- Consolidating multiple features into fewer setups

These measures can reduce small batch CNC machining cost by 15%–30%.

How to Choose the Right Low Volume CNC Machining Manufacturer

A reliable supplier should offer:

- Experience with small-batch production

- Strong DFM and engineering support

- Flexible scheduling and fast turnaround

- Transparent pricing and quality control

Supplier capability directly impacts cost stability and delivery reliability.

Final Thoughts on Low Volume CNC Machining

Low volume CNC machining provides a practical balance between flexibility, precision, and cost efficiency. By understanding material options, tolerance impact, and pricing structure, companies can make informed sourcing decisions.

If you are looking for a reliable partner for small batch CNC machining with strong engineering support and competitive pricing, Weldo Machining offers flexible low-volume CNC machining solutions tailored to your project needs. Contact us today to receive technical guidance and a detailed quotation.