Medical CNC machining is essential for producing precise and reliable parts used in medical devices, implants, and surgical instruments. medical CNC machining cost is influenced by several factors, including material choice, part complexity, machining processes, and surface treatments. In this article, we explore the key materials commonly used, the machining processes involved, and cost-saving strategies. Additionally, we will discuss considerations for both prototyping and mass production, as well as the importance of Design for Manufacturability (DFM) in reducing overall costs.

Key Materials in Medical CNC Machining

Several materials are widely used in medical CNC machining due to their biocompatibility, durability, and suitability for medical applications. Some of the most common materials include:

- Stainless Steel

Stainless steel, especially grades like 316L, is commonly used for surgical instruments, implants, and medical equipment due to its strength, resistance to corrosion, and ability to withstand sterilization processes. - Titanium

Titanium and its alloys, such as Ti-6Al-4V, are favored for their excellent biocompatibility and high strength-to-weight ratio. - Plastics

Materials like PEEK (Polyether Ether Ketone), PTFE (Polytetrafluoroethylene), and UHMWPE (Ultra-High-Molecular-Weight Polyethylene) are used for medical components such as spinal implants, wear-resistant parts, and sterilizable medical devices due to their chemical resistance, flexibility, and low friction properties. - Aluminum

Aluminum is used in lightweight medical devices, robotic surgery tools, and diagnostic equipment. - Cobalt-Chromium

Cobalt-chromium alloys are utilized in implants and prosthetics because of their strength, wear resistance, and biocompatibility. - Medical-Grade Ceramics

Biocompatible ceramics are used for joint replacements, dental devices, and orthopedic implants due to their wear resistance and longevity.

Common Medical CNC Machining Processes

Several CNC machining processes are commonly used in the medical industry to manufacture precise parts and components, including:

- CNC Milling: Used for shaping parts, creating cavities, and drilling holes.

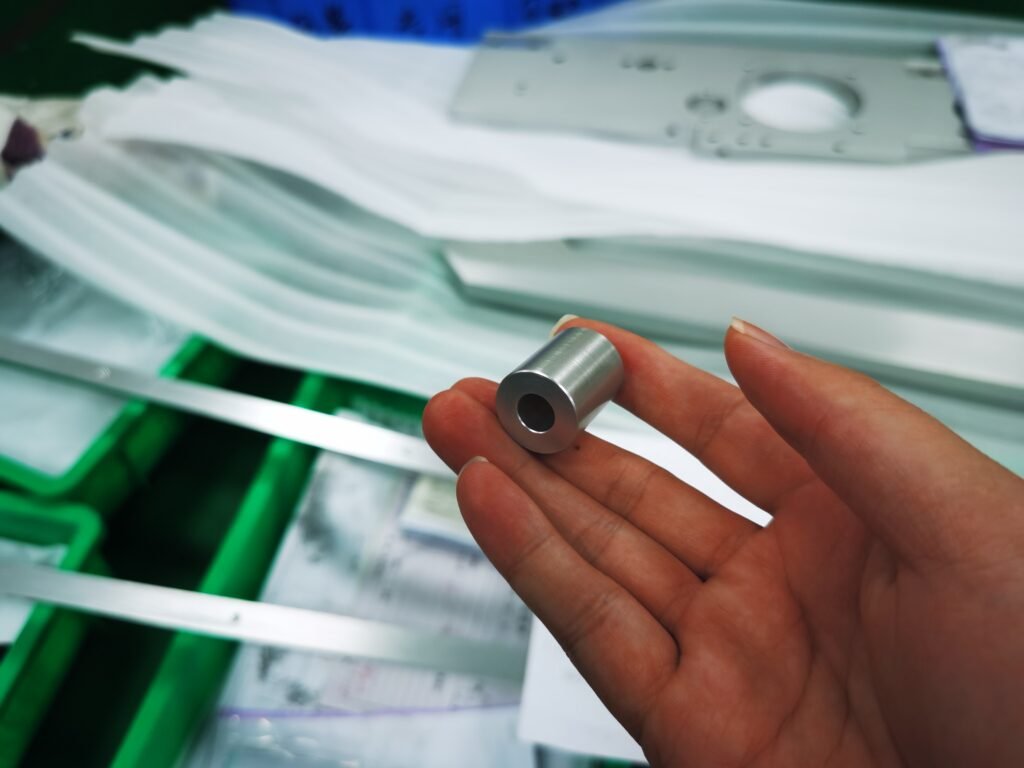

- CNC Turning: Ideal for producing cylindrical medical components such as prosthetics, implants, and diagnostic equipment.

- Electrical Discharge Machining (EDM): Used for intricate parts with tight tolerances, often employed for tools, electrodes, and specialized medical devices.

- Grinding: This process is used to achieve extremely tight tolerances and smooth finishes, particularly in implants and surgical tools.

Surface Treatment Processes

The medical industry demands high standards of cleanliness and durability. Several surface treatments are commonly used to improve the performance and biocompatibility of CNC-machined medical components:

- Anodizing: Used primarily for aluminum parts, anodizing increases surface hardness and corrosion resistance.

- Passivation: Stainless steel parts undergo passivation to enhance their resistance to corrosion by removing free iron from the surface.

- Electropolishing: This process improves the surface finish of stainless steel and titanium parts, reducing roughness and enhancing biocompatibility.

- Plating: Gold, nickel, and other metal coatings are often applied to improve wear resistance and provide electrical conductivity in medical devices.

Medical CNC Surface Finishing Cost– Price Reference

1. Anodizing (Aluminum Parts)

| Type | Price Range |

|---|---|

| Standard anodizing (clear/black) | $0.10 – $0.30 / piece (small parts) |

| Color anodizing | $0.20 – $0.50 / piece |

| Hard anodizing | $0.80 – $2.50 / piece |

Medical-grade anodizing usually falls on the higher end due to film consistency and strict quality requirements.

2. Passivation (Stainless Steel)

| Type | Price Range |

|---|---|

| Standard stainless-steel passivation (304/316) | $0.15 – $0.40 / piece |

| Medical-grade passivation (ASTM A967 / ISO compliant) | $0.30 – $0.80 / piece |

Passivation is one of the lowest-cost finishing options, commonly used for surgical tools and metal fittings.

3. Electropolishing (Stainless Steel / Titanium)

| Type | Price Range |

|---|---|

| Stainless steel electropolishing | $0.80 – $3.00 / piece |

| Titanium electropolishing | $1.50 – $4.00 / piece |

| Medical implant-grade electropolishing | $2.50 – $6.00 / piece |

Electropolishing is one of the higher-cost finishes in the medical sector, especially for implants such as bone screws and joint components.

4. Metal Plating

Different metal coatings vary significantly in price:

| Coating Type | Price Range |

|---|---|

| Nickel plating | $0.30 – $1.20 / piece |

| Gold plating (thin layer for signal/contact pads) | $1.00 – $5.00 / piece |

| Thick gold plating (>1 μm) | $3.00 – $12.00 / piece |

| Silver plating | $0.80 – $2.50 / piece |

| Medical-grade plating (ISO / RoHS compliant) | $1.50 – $10.00 / piece |

Gold and nickel plating are widely used in medical devices, especially for electrical contact points and diagnostic equipment components.

Factors Affecting Surface Finishing Cost

Prices vary depending on:

- Part size (larger parts cost more)

- Batch quantity (higher volumes reduce unit cost)

- Material type (titanium electropolishing is the most expensive)

- Medical-grade certification requirements (ISO 13485, FDA device class)

- Surface roughness (Ra) targets

- LOGO/marking or secondary finishing requirements

Medical Device Components and Accessories

In addition to the materials and processes, several medical devices and their components are frequently machined using CNC technology. These include:

- Surgical Instruments: Forceps, scalpels, and tweezers made from stainless steel or titanium for durability and precision.

- Dental Tools: Tools like drills, scalers, and orthodontic components made from stainless steel and high-strength alloys.

- Orthopedic Implants: Components like knee, hip, and shoulder implants made from cobalt-chromium or titanium.

- Spinal Implants: Parts such as screws, rods, and cages made from PEEK and titanium.

- Medical Robotics: Precision parts for robotic surgery systems, often made from aluminum or stainless steel.

- Diagnostic Equipment Components: Housing and connectors used in MRI machines, X-ray equipment, and other diagnostic tools.

Tolerance Standards for Medical CNC Machining

Tolerance standards are essential in medical CNC machining to ensure precision and reliability. The typical tolerance grades used in medical device manufacturing include:

- Class 1: ±0.0005 inch (±0.0127 mm) – Used for high-precision parts such as surgical instruments and implantable devices.

- Class 2: ±0.001 inch (±0.0254 mm) – Often used for non-implantable medical components.

- Class 3: ±0.005 inch (±0.127 mm) – Suitable for less critical parts such as housing and certain accessories.

- ISO 13485: This international standard ensures the quality management system for the design and manufacture of medical devices is maintained to meet regulatory requirements.

Reduction Strategies in Medical CNC Machining Cost

Several strategies can be implemented to reduce the cost of medical CNC machining without sacrificing quality:

- Material Optimization: Select cost-effective materials that meet the performance and regulatory requirements while minimizing unnecessary costs.

- Design Optimization: Simplify part geometry where possible to reduce machining time and material waste. Implementing Design for Manufacturability (DFM) principles ensures parts are easy to manufacture and cost-effective.

- Batch Production: Larger batch production runs allow for the spreading of fixed costs, such as setup fees, across more parts, thus lowering the cost per unit.

- Advanced Automation: Implementing robotic systems and automated machining operations can improve throughput and reduce labor costs.

Prototype Development and Mass Production Considerations

When transitioning from prototype development to mass production, several factors should be considered:

- Prototyping

- Mass Production

- Tooling

The Importance of DFM

DFM is critical in ensuring that a product is designed in a way that simplifies and optimizes the manufacturing process. Some key principles of DFM in medical CNC machining include:

- Simplifying Part Geometry

- Material Selection

- Standardized Tolerances

Calculate Medical CNC Machining Cost — Summary

Medical CNC machining cost is determined by five core factors: material, machining time, tolerance level, surface finishing, and production quantity. Because medical devices require higher precision, biocompatible materials, and strict quality compliance, costs are higher than standard CNC machining.

1. Material Cost

Medical-grade materials are more expensive due to biocompatibility and certification requirements.

Common medical materials & typical cost impact

- Titanium (Ti-6Al-4V): High cost, slow machining → highest impact

- Stainless Steel 316L: Medium cost, good machinability → moderate impact

- PEEK / PTFE / UHMWPE: High material price + precise cutting → high impact

- Aluminum 6061-T6 / 7075: Lower cost → low/medium impact

Formula:

Material Cost = Material Price × Required Volume + Scrap/Waste Rate

2. Machining Time (Primary Cost Driver)

Medical components often have complex geometry and tight tolerances, increasing CNC runtime.

Machining time depends on:

- Number of operations (milling, turning, EDM, drilling)

- Part geometry complexity

- Tight tolerance zones (±0.001 inch or better increases time)

- Tool wear and feed rate adjustments (especially for titanium and PEEK)

Formula:

Machining Cost = Machining Time (hours) × Machine Hourly Rate

Machine hourly rates vary:

- 3-axis CNC: $30–$60/hr

- 4/5-axis CNC: $60–$120/hr

- EDM: $70–$150/hr

3. Tolerance Requirements

Medical parts often require:

- Class 1: ±0.0005 inch

- Class 2: ±0.001 inch

- ISO 13485-compliant QC

Tighter tolerances = slower feeds + more tool changes + extra inspection.

Cost impact:

Tight tolerances can increase machining cost by 10–40%.

4. Surface Finishing Cost

Common finishes and typical unit costs:

- Anodizing: $0.10–$2.50

- Passivation: $0.15–$0.80

- Electropolishing: $0.80–$6.00

- Gold/Nickel plating: $0.30–$12.00

Medical applications often require smooth Ra, resulting in additional polishing or grinding.

5. Quality Control & Certification Cost

Medical parts usually require:

- Full inspection

- Material certificates

- Biocompatibility documentation

- ISO 13485 process compliance

These add 5–15% to total cost.

6. Production Quantity

Small batches = higher unit cost

Mass production = significantly lower cost per piece

Prototype pricing is often 2–5× higher due to setup fees and one-off programming.

Final Cost Formula (Practical Version)

Medical CNC Machining Cost =

(Material Cost)

- (Machining Time × Hourly Rate)

- (Surface Finishing)

- (QC & Inspection)

- (Setup/Programming Fee)

– (Mass Production Discount)

Final Thoughts

Medical CNC machining plays a vital role in producing high-quality, precise components for the medical device industry. By carefully considering material selection, machining processes, surface treatments, and cost-saving strategies, manufacturers can reduce costs while maintaining the highest standards of quality and precision. Implementing DFM principles and optimizing production for mass manufacturing can further drive efficiency and cost reductions.

For more information or a custom quote on your medical CNC machining project, contact Weldo Machining today to learn about our capabilities and competitive pricing.