In the medical industry, manufacturing precision, cleanliness, and biocompatibility are essential for safe and effective treatment. A professional medical cnc machining manufacturer plays a crucial role in producing components for surgical instruments, diagnostic devices, orthopedic hardware, dental tools, and laboratory systems. As healthcare technology evolves, CNC machining ensures unmatched accuracy, repeatability, and compatibility with strict medical standards.

A qualified medical cnc machining company must provide precision engineering, medical-grade material processing, and validated machining procedures. This article covers the key materials, applications, surface finishing methods, and capabilities required from a reliable medical cnc machining supplier, along with insights into both metal and plastic processing.

What Defines a High-Quality Medical CNC Machining Manufacturer?

A reliable medical cnc machining manufacturer must have industry-specific knowledge, advanced machining centers, and the ability to meet regulatory requirements. Medical components often require micro-scale structures, tight tolerances, and consistent surface quality.

Core Capabilities of a Medical CNC Machining Supplier

- High accuracy (±0.005–0.02 mm)

- Expertise in both metals and engineering plastics

- Multi-axis machining for complex geometries

- Cleanroom-friendly manufacturing environments

- Material traceability and documentation compliance

- Capacity for both prototyping and production

A true medical cnc machining factory must also ensure parts withstand sterilization, mechanical stress, and long-term clinical usage.

Medical CNC Machining Materials — Metal Category

Metal materials offer exceptional strength and biocompatibility, making them indispensable in medical engineering.

1. Stainless Steel 316L

Properties

- Excellent corrosion resistance

- Biocompatibility suitable for surgical contact

- High durability during repetitive sterilization

Typical Medical CNC Parts

- Surgical clamps and forceps

- Orthopedic screws

- Precision shafts

- Surgical instrument components

2. Titanium Grade 5 (Ti-6Al-4V)

Properties

- Lightweight yet extremely strong

- Superior biocompatibility

- High fatigue resistance

Applications

- Trial implant parts

- Bone fixation components

- Dental implant housings

- Endoscopic tool structures

3. Aluminum 6061 / 7075

Properties

- Lightweight and cost-efficient

- High machinability

- Suitable for non-implant components

Medical Uses

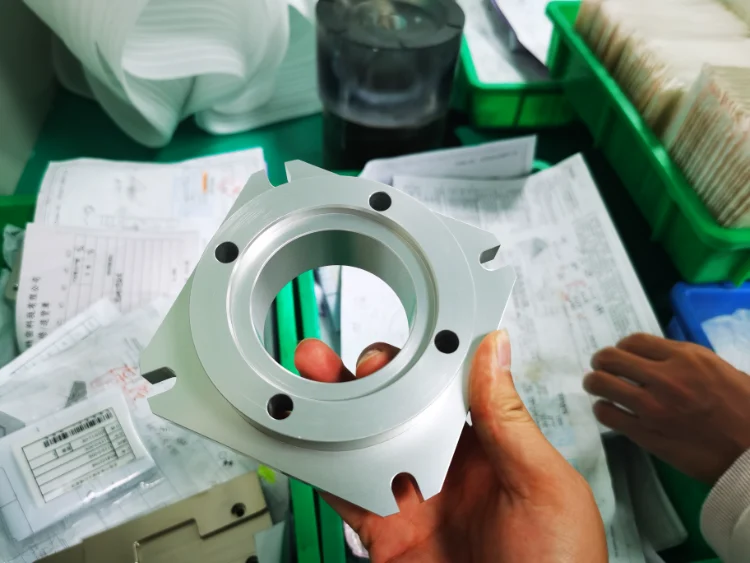

- Device housings

- Diagnostic frames

- Portable instrument components

4. Cobalt-Chrome Alloys

Properties

- Exceptional wear resistance

- High hardness

- Suitable for load-bearing parts

Typical Components

- Joint prototypes

- Spinal device components

- Dental prosthetic frameworks

Medical CNC Machining Materials — Plastic Category

Engineering plastics provide lightweight, sterilization-resistant, and chemically stable solutions for modern medical devices.

1. PEEK (Polyether Ether Ketone)

Advantages

- Autoclave-resistant

- Biocompatible

- High structural strength

Applications

- Surgical handles

- Spinal trial components

- Endoscope instrument parts

2. Polycarbonate (PC)

Advantages

- Transparent

- High impact resistance

- Suitable for diagnostic visibility components

Typical Parts

- Device windows

- Transparent covers

- Measurement housings

3. Delrin / POM

Advantages

- High stiffness

- Low friction

- Dimensional stability

Applications

- Alignment parts

- Positioning blocks

- Sliding medical mechanisms

4. PTFE (Teflon)

Advantages

- Chemically inert

- Non-stick surface

- High thermal resistance

Medical Uses

- Seals

- Manifolds

- Insulating components

5. Ultem (PEI)

Advantages

- High temperature stability

- Sterilization resistant

- Flame-resistant

Typical CNC Parts

- Connectors

- Device frames

- Support structures

Surface Finishing Options for Medical CNC Machining Parts

Surface finishing is essential to ensure medical components meet hygiene, durability, and safety standards. A qualified medical cnc machining manufacturer must provide tailored finishing processes for specific materials and clinical requirements.

1. Passivation (Stainless Steel)

Enhances corrosion resistance and removes contaminants, creating a safer and cleaner surface.

Used For:

- Surgical clamps

- Fasteners

- Precision shafts

2. Anodizing (Aluminum)

Improves wear resistance and enables color coding for medical instrument sets.

Typical Uses:

- Device housings

- Surgical tool frames

- Instrument brackets

3. Electropolishing (High-Cleanliness Metals)

Delivers a mirror-like finish with low surface roughness, ideal for blood-contact or implant-related components.

Parts Finished:

- Surgical blades

- Orthopedic tools

- Dental instruments

4. Polishing & Vapor Smoothing (Plastics)

Improves clarity, reduces friction, and enhances aesthetics for PEEK, PC, and POM components.

Used For:

- PC windows

- PEEK handles

- Diagnostic flow-path components

5. Laser Marking (Traceability)

Ensures compliance with medical serialization and tracking requirements.

Common Applications:

- Surgical instruments

- Device batches

- Regulatory code markings

6. Medical-Grade Deburring & Ultrasonic Cleaning

Removes burrs and contaminants to ensure maximum safety and hygiene.

Applied To:

- Microfluidic blocks

- Dental connectors

- Lab components

Applications of Medical CNC Machining

Medical CNC machining supports a wide range of medical engineering fields:

Surgical Tools

- Clamps

- Scissors

- Micro-blades

Orthopedic Components

- Bone screws

- Fixation plates

- Joint mechanism prototypes

Dental Devices

- Implant components

- Surgical tips

- Precision connectors

Diagnostic & Analytical Equipment

- Instrument frames

- Mounting brackets

- Microfluidic blocks

Advantages of Choosing a Custom Medical CNC Machining Manufacturer

Precision

Ensures accurate geometry for clinical safety.

Flexibility

Supports metals and performance plastics.

Scalability

Suitable for prototypes, small batches, and mass production.

Sterilization Compatibility

Withstands autoclave, gamma, and chemical cleaning.

Engineering Efficiency

Allows rapid modifications without tooling costs.

Request Medical CNC Machining Manufacturer Support — Contact Weldo

Choosing a reliable medical cnc machining manufacturer is crucial for ensuring precision, stability, and regulatory compliance in medical device production. Weldo provides comprehensive machining solutions for metals, plastic materials, and micro-scale components. As a trusted medical cnc machining supplier and technology-driven medical cnc machining factory, Weldo supports projects ranging from surgical tools to diagnostic mechanisms with professional engineering assistance, quick turnaround, and strict tolerance control.

Contact Weldo today for pricing, manufacturing consultation, and expert guidance on any medical CNC machining requirement.

FAQ of medical cnc machining manufacturer

Why are surface finishes important for medical CNC parts?

They enhance corrosion resistance, sterilization compatibility, smoothness, and patient safety while meeting regulatory requirements.

What types of medical applications rely on CNC machining?

Surgical devices, orthopedic components, dental implants, laboratory mechanisms, and diagnostic equipment all depend on CNC machining.

What does a medical CNC machining manufacturer do?

They produce high-precision medical components such as surgical tools, orthopedic parts, dental devices, and diagnostic equipment.