Selecting a reliable medical instrument cnc manufacturer is a critical decision for medical device companies, OEMs, and product developers. Medical instruments require extremely high precision, stable dimensional accuracy, controlled surface quality, and repeatable manufacturing processes. Compared with general CNC machining, medical applications demand stricter control over machining methods, materials, and surface integrity. This page explains the machining processes, quality requirements, surface treatments, and evaluation criteria associated with professional medical CNC manufacturing.

What Is a Medical Instrument CNC Manufacturer?

A medical instrument cnc manufacturer is a specialized precision machining service provider that produces components for medical instruments, surgical tools, diagnostic equipment, and healthcare devices using CNC milling, CNC turning, multi-axis machining, and precision cutting technologies.

Key differences from general machining suppliers include:

- Tighter tolerances and repeatability

- Experience with medical-grade metals and plastics

- Controlled machining and inspection processes

- Focus on clean edges and functional surfaces

A professional medical instrument cnc manufacturer supports both product performance and long-term manufacturing stability.

Core Machining Processes for Medical Instruments

CNC Milling for Medical Components

CNC milling is widely used to manufacture:

- Medical device housings

- Structural frames

- Complex multi-surface components

3-axis to 5-axis CNC milling enables complex geometries while maintaining tight tolerances and consistent surface quality.

CNC Turning for Precision Medical Parts

CNC turning is essential for producing:

- Shafts and pins

- Cylindrical connectors

- Rotational medical components

High-precision turning ensures concentricity, diameter consistency, and smooth finishes required in medical instruments.

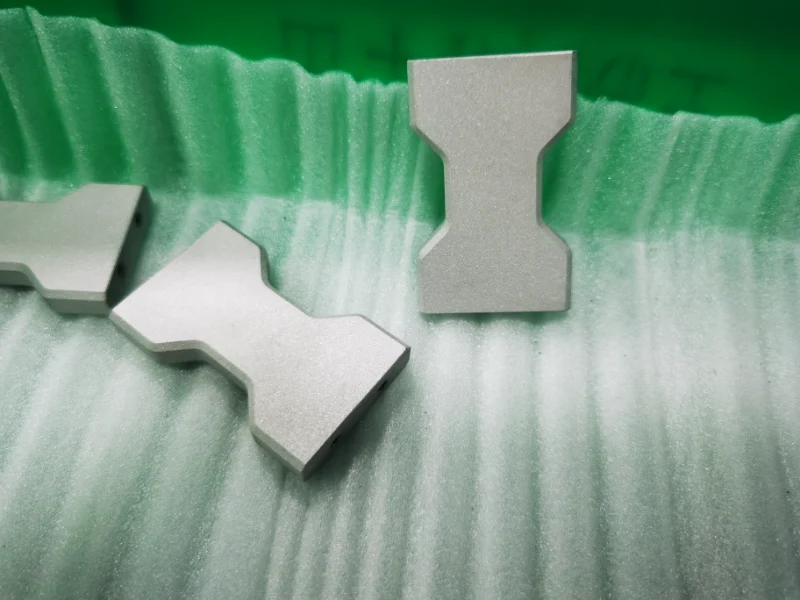

Wire EDM Machining for Medical Applications

Wire EDM machining plays an important role in medical instrument manufacturing, especially for parts requiring:

- Extremely tight tolerances

- Sharp internal corners

- Thin-wall or delicate structures

Wire EDM machining is commonly used for:

- Precision slots and profiles

- Complex internal geometries

- Hardened metal medical components

Because wire EDM machining is a non-contact cutting process, it minimizes mechanical stress and deformation. This makes it particularly suitable for medical instrument parts that require high accuracy, burr-free edges, and excellent dimensional control.

Prototype to Production Machining

A capable medical instrument cnc manufacturer supports:

- Rapid CNC prototyping

- Low-volume pilot production

- Stable batch manufacturing

This flexibility supports medical product development and validation cycles.

Key Requirements in Medical Instrument CNC Manufacturing

Precision and Dimensional Control

Medical components often require:

- Tight tolerances (commonly ±0.01 mm or better)

- High repeatability across batches

- Stable and documented machining processes

Precision control is fundamental for any medical instrument cnc manufacturer.

Material Capability

Medical CNC machining commonly involves:

Each material requires different cutting strategies and finishing approaches.

Surface Treatment Processes for Medical CNC Machined Parts

Surface treatment directly affects cleanliness, corrosion resistance, usability, and compatibility with sterilization processes. A professional medical instrument cnc manufacturer must support multiple medical-appropriate finishing methods.

Mechanical Surface Finishing

- Fine polishing

- Brushing

- Micro-bead blasting

These processes remove machining marks and improve surface smoothness.

Passivation

Passivation is commonly applied to stainless steel medical components to:

- Improve corrosion resistance

- Remove surface contaminants

- Enhance biocompatibility

Anodizing (for Aluminum Medical Parts)

Medical anodizing provides:

- Improved corrosion resistance

- Increased surface hardness

- Optional color coding for identification

Electropolishing

Electropolishing is widely used for surgical instruments to:

- Achieve ultra-smooth surfaces

- Reduce bacterial adhesion

- Improve sterilization compatibility

Plating and Medical Coatings

Depending on application requirements:

- Nickel plating

- Chrome plating

- Medical-grade protective coatings

Surface treatments are selected based on function, material, and regulatory expectations.

Medical Manufacturing Standards and Quality Expectations

Medical CNC machining suppliers must align with industry quality expectations, including:

- ISO 9001 quality management systems

- Material traceability and documentation

- First Article Inspection (FAI)

- In-process and final dimensional inspection

Strong quality discipline is essential for medical instrument cnc manufacturing.

Common Challenges in Medical Instrument CNC Manufacturing

Small and Complex Part Geometry

Medical components are often compact and intricate.

Solution:

- High-precision CNC equipment

- Optimized fixturing

- Wire EDM machining for complex internal features

Tight Tolerances with Repeatability

Medical production demands consistency across batches.

Solution:

- Stable process parameters

- Tool wear monitoring

- Layered inspection systems

Surface Finish and Burr Control

Sharp edges and burrs are unacceptable in medical instruments.

Solution:

- Fine finishing passes

- Secondary deburring and polishing

- Visual and dimensional inspection

An experienced medical instrument cnc manufacturer integrates these controls into daily production.

Typical Applications of Medical Instrument CNC Manufacturing

Medical CNC machining is commonly used for:

- Surgical instrument components (handles, clamps, blades)

- Orthopedic and trauma device parts

- Diagnostic and laboratory equipment housings

- Medical device structural components

Each application places different demands on machining accuracy and surface integrity.

How to Choose the Right Medical Instrument CNC Manufacturer

When evaluating medical CNC machining suppliers, buyers should consider:

- Experience with medical components

- Capability to hold tight tolerances consistently

- Availability of advanced processes such as wire EDM machining

- Surface finishing and inspection capability

- Ability to scale from prototype to production

A reliable medical instrument cnc manufacturer reduces manufacturing risk and supports long-term product success.

Cost Considerations in Medical CNC Manufacturing

Medical CNC machining costs depend on:

- Part complexity and geometry

- Material selection

- Tolerance and surface finish requirements

- Order quantity

Total cost should be evaluated based on quality stability and yield, not unit price alone.

Conclusion: Partner with a Professional Medical Instrument CNC Manufacturer

Choosing the right medical instrument cnc manufacturer is essential for ensuring product safety, precision, and manufacturing stability. Medical components require advanced machining processes, controlled surface treatments, and disciplined quality management. Working with an experienced CNC manufacturer helps reduce risk and improve long-term production efficiency.

If you are looking for a reliable partner with strong medical CNC machining capability, Weldo Machining can provide professional engineering support, precision manufacturing, and competitive quotations. Contact us today to discuss your medical instrument project in detail.