Metal CNC machining prototype production has become a cornerstone of modern engineering, enabling companies to validate designs, test functionality, and accelerate time-to-market. From early-stage concept samples to functional parts ready for rigorous testing, the ability to produce a reliable metal CNC machining prototype quickly and accurately gives manufacturers a major competitive advantage.

Why Metal CNC Machining Prototype Services Matter in Early Product Development

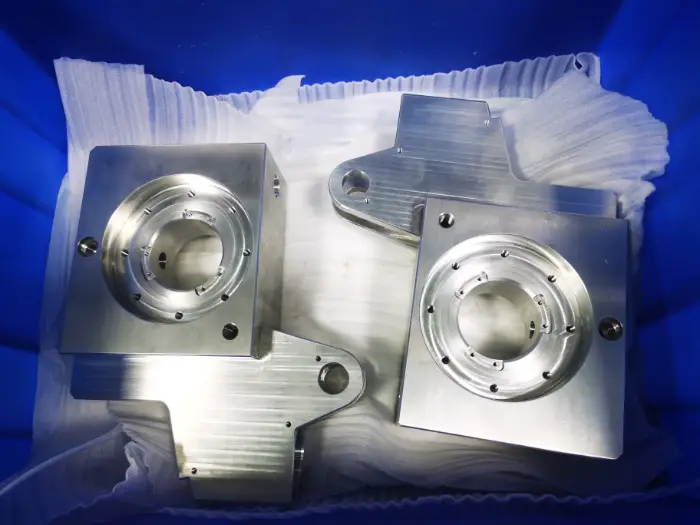

A well-executed metal CNC machining prototype allows engineers to confirm tolerance requirements, verify mechanical strength, and evaluate manufacturability. Unlike digital simulations, a physical prototype reveals real-world performance, interaction with assemblies, thermal efficiency, and overall dimensional consistency.

Compared with plastic or composite samples, metal prototypes offer durability suitable for load testing, wear evaluation, fatigue studies, and end-use verification. This makes metal CNC prototyping ideal for aerospace, medical devices, automotive components, robotics hardware, consumer electronics, and industrial equipment.

Capabilities Required for High-Quality Metal CNC Machining Prototype Production

Multiaxis Machining Capabilities for Complex Metal Samples

Many advanced designs require 3-axis, 4-axis, or 5-axis machining to achieve undercuts, deep pockets, thin walls, curved profiles, and multi-surface geometries.

A robust metal CNC machining prototype workflow should support:

- 5-axis contouring for complex aerospace brackets

- Tight-tolerance cavities for medical housings

- Precision mounting features for automotive parts

- Rapid machining of functional metal assemblies

This ensures that the metal CNC machining sample accurately reflects final production intent.

Tolerances and Dimensional Accuracy Expected in Metal Prototyping

Typical CNC metal prototype tolerances:

| Feature | Standard Tolerance | Tight Tolerance |

|---|---|---|

| Metal CNC milling | ±0.05 mm | ±0.01–0.02 mm |

| Metal CNC turning | ±0.05 mm | ±0.005–0.02 mm |

| Hole / shaft fits | ISO 2768-F | Custom fits available |

| Flatness / Parallelism | 0.05–0.1 mm | 0.01–0.03 mm |

Such precision ensures that the metal CNC machining prototype can serve for both verification and pre-production.

Metal Materials Suitable for CNC Prototyping

A professional machining supplier should offer a wide range of materials to support different functional requirements:

- Aluminum (6061-T6, 7075-T6, 2024) – Lightweight, strong, cost-effective

- Stainless steel (304, 316L, 17-4PH) – Corrosion resistance & strength

- Tool steel (D2, A2, H13) – High wear and impact resistance

- Brass / Bronze – Excellent machinability, electrical properties

- Titanium (Ti-6Al-4V) – Lightweight but extremely strong for aerospace & medical

- Magnesium alloys – Ultra-lightweight prototyping for automotive / robotics

Different materials contribute to a more realistic and functional metal CNC machining prototype, especially when targeting high-performance industries.

Working Through a Metal CNC Machining Prototype Workflow

Step 1 – Design Review & Manufacturability Evaluation

Engineers and machinists review the CAD model to ensure:

- Structural support for machining

- Feasible wall thickness

- Appropriate tolerances for the material

- Avoidance of unnecessary complexity or cost

Clients often receive a metal CNC machining sample feasibility report (DFM) before production.

Step 2 – Rapid Programming & CNC Setup

CAM programming, toolpath strategies, and material selection are finalized. The goal is to optimize cycle time while maintaining accuracy.

Step 3 – Prototype Machining & Quality Inspection

During machining, critical features such as threads, bores, channels, and interfaces are monitored closely.

Inspection may include:

- CMM measurements

- Surface roughness checks

- Hardness tests

- Visual and dimensional reporting

Step 4 – Surface Finishing for Metal CNC Samples

Common finishing options:

- Bead blasting

- Anodizing (Type II / Type III)

- Passivation

- Electropolishing

- Powder coating

- Nickel, chrome, or zinc plating

Finishing provides aesthetic, functional, or corrosion-resistant improvements to the metal CNC machining prototype.

Step 5 – Iteration & Pre-Production Transition

Prototype feedback helps refine:

- Material selection

- Tolerance adjustments

- Cost optimization

- Assembly interaction

Once approved, the same machining strategy can scale to small or medium-batch production.

Typical Costs for Metal CNC Machining Prototype Projects

Pricing for metal CNC machining prototype development varies based on geometry, tolerance, material, and finishing. Typical ranges (USD):

| Part Complexity | Price Range |

|---|---|

| Simple metal CNC machining sample | $30 – $80 |

| Medium-complex prototype | $80 – $250 |

| High-precision 5-axis prototype | $250 – $800+ |

| Titanium / hardened steel sample | $120 – $600+ |

Additional cost drivers include:

- Small features requiring micro-tooling

- Extremely tight tolerances

- Multi-step finishing processes

- Urgent lead-time requirements

- Low-volume special material procurement

A reliable manufacturer should provide transparent pricing and suggestions for optimizing cost without compromising functionality.

Common Questions When Ordering a Metal CNC Machining Prototype

How Fast Can a Metal Prototype Be Delivered?

Most simple prototypes ship within 3–5 days.

Complex parts requiring 5-axis machining or special finishes may take 7–12 days.

Can a Prototype Be Used as a Functional Part?

Yes — especially when produced from final-grade metal materials.

Many customers use metal CNC machining samples for real-world stress, performance, and fatigue testing.

Are Tight Tolerances Achievable on a Metal CNC Machining Prototype?

Professional machining shops routinely achieve ±0.01–0.02 mm tolerances depending on material and geometry.

What If I Need Multiple Iterations?

Rapid CNC workflows support frequent design cycles. Many companies request two–three rounds before moving to pre-production.

Can Prototyping Transition to Production?

A qualified shop provides consistent documentation, process control, and machining strategies — enabling seamless transition from metal CNC machining prototype to volume manufacturing.

Conclusion: Build Better Metal CNC Machining Prototype Projects with Weldo Machining

A well-made metal CNC machining prototype shortens development cycles, reduces engineering risks, and provides accurate insight into final part performance. Whether you require a single metal CNC machining sample or multiple prototypes for iterative testing, choosing a capable manufacturing partner is crucial.

Weldo Machining delivers high-precision metal CNC prototypes, broad material options, tight tolerances, fast turnaround, and full DFM support.

If you need reliable prototype machining or want a customized quotation, contact Weldo Machining today — our engineers are ready to review your design and provide expert guidance.