The development of any successful metal part begins long before mass production. Today’s engineers, designers, and product teams rely heavily on metal CNC machining sample workflows to validate concepts, refine tolerances, and test performance under real-world conditions. Fast, repeatable, and cost-efficient, prototype machining is the backbone of modern hardware innovation.

Understanding the Role of Metal CNC Machining Sample in Product Development

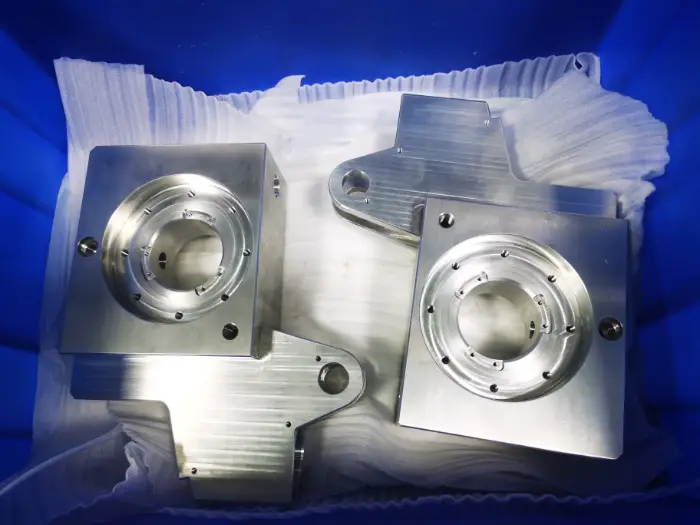

A metal CNC machining sample is far more than a simple test piece. It functions as the first fully functional representation of a part, replicating geometry, material properties, surface quality, and structural integrity. Because prototypes can be machined from the same alloys used for final production—aluminum, steel, stainless steel, titanium, brass—they offer unmatched accuracy compared with resin or printed concepts.

When a project requires realistic mechanical testing, thermal evaluation, stress analysis, or assembly validation, machining becomes the preferred route over alternatives like 3D printing. This is why industries such as aerospace, automotive, robotics, and medical devices depend heavily on precise prototype machining.

How Metal CNC Machining Sample Development Accelerates Iteration

A crucial stage in early engineering is producing a reliable metal CNC machining sample that allows teams to inspect dimensions, test tolerances, and evaluate manufacturability before approving final drawings.

Metal Prototype Machining for Functional Validation

Unlike conceptual mockups, functional prototypes must withstand actual use scenarios. Metal prototype machining ensures characteristics such as hardness, tensile strength, machinability, and thermal stability match production-grade parts. This allows teams to assess:

- Fit and alignment with other components

- Thread integrity and engagement

- Load-bearing performance

- Heat resistance and distortion levels

- Surface finish compatibility with coatings or plating

CNC Metal Prototype Service for Faster Market Entry

Speed-to-market is everything. A dependable CNC metal sample service can cut development cycles dramatically by providing:

- Faster quoting

- Design for manufacturability (DFM) insights

- Quick-turn machining

- Repeatable tolerances for multiple design versions

This enables engineers to rapidly correct errors, introduce improvements, and progress confidently to the pre-production phase.

Custom Metal Prototypes and the Importance of Material Selection

Material choice is one of the most important technical decisions during metal CNC machining prototype development. Each material behaves differently during machining, surface finishing, and functional testing.

Common Materials Used in Precision Prototypes

- Aluminum alloys (6061, 7075, 2024) — light, strong, cost-effective

- Stainless steels (304, 316, 17-4PH) — corrosion-resistant and extremely durable

- Carbon steels — ideal for high-strength applications

- Brass / Bronze — excellent machinability and aesthetic appeal

- Titanium — strong, biocompatible, used in aerospace and medical components

Selecting the wrong material can lead to warping, cracking, or unexpected wear. A machining partner with expertise in metallurgy can guide proper material selection based on part geometry and expected performance.

Rapid Metal Machining for Tight-Tolerance Prototype Requirements

Prototype success often depends on whether tolerances can match production expectations. Modern rapid metal machining can achieve extremely tight specifications, typically:

- ±0.01–0.05 mm for standard geometries

- ±0.005 mm for high-precision features (bores, critical fits)

- Surface roughness Ra 0.8–3.2 μm depending on requirements

Such precision makes CNC machining irreplaceable in industries requiring extremely accurate alignment or load-bearing performance.

When Should You Use CNC Machining Instead of 3D Printing?

Choose machining when you require:

- Real metal properties

- High dimensional accuracy

- Superior surface finish

- Threads, deep cavities, or tight fits

- Parts that must withstand pressure, heat, or mechanical stress

This makes machining the ideal pathway for metal CNC machining sample workflows where reliability is key.

Cost Factors of Metal CNC Machining Sample Projects

Prototype machining costs vary widely because projects differ in geometry, material, tolerances, and finishing.

Common factors include:

1. Complexity of Geometry

More features = longer machining time

Deep pockets, narrow ribs, and undercuts can raise cost.

2. Metal Material Type

Soft materials like aluminum are cheaper to cut, while titanium or stainless steel require slower feeds, harder tools, and more time.

3. Tolerance Requirements

Any tolerance tighter than ±0.02 mm significantly increases machine time and inspection requirements.

4. Finishing & Post-Processing

Common additions include anodizing, bead blasting, polishing, passivation, plating, and heat treatment.

Typical Metal CNC Prototype Price Range

- Simple aluminum prototype: $30–$120/pc

- Medium complexity stainless steel: $80–$250/pc

- High-precision titanium prototype: $150–$500+/pc

These numbers vary depending on quantity, lead time, and finishing requirements.

Common Challenges in Metal CNC Machining Sample Projects

Warping in Thin-Wall Designs

Thin-walled metals can vibrate or distort during cutting. Proper strategy and fixturing minimize risk.

Overly Tight Tolerances Requested Without Necessity

Some designers apply blanket tolerances that raise cost unnecessarily. Strategic tolerance allocation reduces cost without affecting performance.

Misalignment Between Prototype and Mass Production Feasibility

A prototype that works does not always scale well. Choosing scalable machining processes early prevents redesign delays.

Inconsistent Results When Using Low-Quality Vendors

Cheaper providers may deliver prototypes with poor repeatability, incorrect tolerances, or non-certified materials.

Conclusion — Partnering with the Right Metal CNC Machining Sample Expert

A successful metal CNC machining sample process requires precision, experience, and technical insight. From selecting the right metal to producing tight-tolerance parts ready for real-world testing, the path to a reliable final product starts with the right machining partner.

At Weldo Machining, we specialize in delivering accurate prototypes, rapid iterations, and production-ready machining that support your engineering goals from the first concept to full-scale manufacturing.

Contact us today for expert guidance, instant quotes, and professional machining solutions built for high-performance metal components.