Multi axis CNC machining is an advanced manufacturing method that enables complex geometries, higher accuracy, and reduced setup time compared with traditional 3-axis machining. As product designs become more complex and tolerance requirements tighter, multi axis CNC machining has become essential across aerospace, medical, industrial, and high-end manufacturing sectors.

What Is Multi Axis CNC Machining

Multi axis CNC machining refers to CNC machining processes that operate on more than three axes simultaneously. In addition to the standard X, Y, and Z axes, multi axis machining incorporates rotary or tilting axes, allowing the cutting tool or workpiece to approach the part from multiple directions in a single setup.

Common configurations include:

- 4 axis CNC machining

- 5 axis CNC machining

- Simultaneous multi axis machining

Compared with conventional machining, multi axis CNC machining improves precision, efficiency, and geometric freedom.

Why Multi Axis CNC Machining Is Used in Modern Manufacturing

The primary advantage of multi axis CNC machining lies in its ability to machine complex features without repeated repositioning.

Key benefits include:

- Fewer setups and reduced alignment error

- Improved surface quality on complex contours

- Shorter lead times for complex parts

- Higher dimensional consistency

These advantages make multi axis CNC machining ideal for both prototyping and production.

Materials Used in Multi Axis CNC Machining

Material behavior directly affects tool selection, cutting parameters, and inspection methods.

Multi Axis CNC Metal Machining Materials

Multi axis CNC metal machining commonly involves:

- Aluminum alloys (6061, 7075, 7050)

Lightweight, stable, and highly machinable for aerospace and industrial components. - Stainless steel (304, 316, 17-4PH)

Used for strength and corrosion resistance, requiring careful heat and tool control. - Titanium alloys

Widely applied in aerospace and medical parts, demanding low cutting speed and rigid fixturing. - Inconel and superalloys

Suitable for high-temperature environments, with higher machining cost and tool wear.

Multi Axis CNC Plastic Machining Materials

Multi axis CNC plastic machining is used for precision non-metal components.

Common plastics include:

- PEEK – high temperature and chemical resistance

- PTFE – low friction and insulation

- POM (Delrin) – dimensional stability

- Nylon and PC – cost-effective engineering plastics

Plastic materials require optimized feeds and speeds to avoid deformation.

Multi Axis CNC Machining Process Guidelines

Effective multi axis CNC machining depends on process planning and control.

CAD/CAM Programming

Accurate toolpath programming is critical. CAM software must manage:

- Tool orientation and collision avoidance

- Smooth axis transitions

- Optimal cutting angles

Poor programming can negate the advantages of multi axis CNC machining.

Fixturing and Workholding

Stable fixturing is essential because multi axis CNC machining often applies cutting forces from multiple directions. Fixtures must minimize deformation while allowing full tool access.

Tool Selection and Toolpath Strategy

- Use short, rigid cutting tools when possible

- Optimize step-over and step-down values

- Avoid unnecessary simultaneous axis motion

These strategies improve accuracy and tool life.

Key Considerations in Multi Axis CNC Machining

Multi axis CNC machining introduces unique operational challenges.

Important considerations include:

- Machine kinematic accuracy

- Thermal stability

- Axis synchronization

- Tool length and interference control

Ignoring these factors can lead to dimensional deviation.

Factory Management Priorities for Multi Axis CNC Machining

Managing a multi axis CNC machining workshop requires stricter discipline than standard machining.

Key management priorities include:

- Machine calibration and maintenance schedules

- Standardized programming procedures

- Tool life monitoring systems

- Clear documentation and revision control

Consistency at the factory level ensures long-term process stability.

Personnel Safety in Multi Axis CNC Machining

Safety is especially critical due to complex machine motion.

Key safety measures include:

- Operator training on multi-axis movement paths

- Strict machine enclosure and interlock systems

- Proper chip and coolant management

- Emergency stop and safety protocol enforcement

A safe environment protects both personnel and equipment.

Material Inspection Before Multi Axis CNC Machining

Material quality directly affects final part accuracy.

Pre-machining inspection should include:

- Material certification verification

- Dimensional and flatness checks

- Internal stress assessment for metals

Proper material inspection reduces scrap and rework.

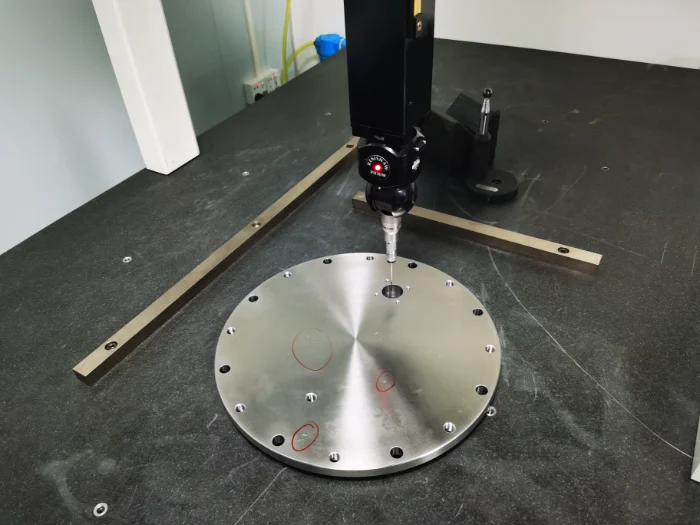

Finished Part Inspection in Multi Axis CNC Machining

Inspection is a core component of multi axis CNC machining.

Common inspection methods include:

- Coordinate Measuring Machine (CMM) inspection

- In-process probing

- Optical and surface roughness measurement

Inspection data ensures that multi axis CNC results meet design requirements.

Advantages of Multi Axis CNC Machining

Multi axis CNC machining offers significant benefits:

- Ability to machine complex geometries

- Higher accuracy due to fewer setups

- Improved surface finish

- Reduced overall machining time

- Better repeatability for complex parts

These advantages often outweigh the higher equipment cost.

Limitations of Multi Axis CNC Machining

Despite its strengths, multi axis CNC machining has limitations:

- Higher machine and software investment

- More complex programming requirements

- Greater operator skill requirements

- Higher setup and planning time

Understanding these limitations helps determine when multi axis CNC machining is the right choice.

Wholesale Multi Axis CNC Machining Considerations

Wholesale multi axis CNC machining focuses on batch production and cost optimization.

Key factors include:

- Program reuse across batches

- Standardized fixturing

- Stable material sourcing

- Volume-based cost reduction

Wholesale production benefits most from process repeatability.

Typical Applications of Multi Axis CNC Machining

Multi axis CNC machining is widely used in:

- Aerospace structural and engine components

- Medical implants and instruments

- Industrial automation parts

- Energy and power equipment

- Precision molds and tooling

Complex geometry and high accuracy drive adoption in these industries.

Coordinating Multi-Axis CNC Machining with 3-Axis CNC Machining: Methods and Trade-Offs

In real-world production, multi-axis CNC machining—especially 5-axis machining—is rarely used to complete every operation alone. To balance efficiency, cost, and accuracy, coordinating multi-axis CNC machining with 3-axis CNC machining is a mature and widely adopted manufacturing strategy.

1. Rough Machining with 3-Axis CNC, Followed by Multi-Axis CNC Finishing

Process Logic

In this approach, 3-axis CNC machining is used to remove most of the raw material efficiently, after which the part is transferred to a multi-axis CNC machine to finish complex surfaces, angled features, and high-precision areas.

Typical workflow:

- 3-axis CNC performs rough contouring, pocketing, and planar machining

- A controlled machining allowance is left (typically 0.3–1.0 mm)

- Multi-axis CNC completes finishing in one or a few setups

Advantages

- Reduces multi-axis machine occupancy, improving utilization of high-value equipment

- Improves overall machining efficiency due to faster material removal on 3-axis machines

- Minimizes tool wear on multi-axis machines, lowering total machining cost

- Clear and repeatable process flow, suitable for standardization

Limitations and Considerations

- Requires accurate control of roughing allowance to avoid undercutting or excess finishing time

- Introduces potential repositioning errors, requiring consistent datum and fixturing strategies

2. Multi-Axis CNC Machining First, Followed by Single-Face Material Removal on 3-Axis CNC

Process Logic

For some complex parts, multi-axis CNC machining is primarily used to complete critical geometries, deep cavities, and multi-angle features. Afterward, 3-axis CNC machining can be used to remove excess material on a single face or non-critical area.

Typical follow-up operations include:

- Single-face stock removal

- Planar finishing

- Edge trimming and chamfering

- Secondary hole or feature machining

Advantages

- Frees up multi-axis CNC capacity by shifting simple operations to 3-axis machines

- Lowers unit machining cost, as 3-axis machines are more economical

- Improves process flexibility for design adjustments or local corrections

Limitations and Considerations

- Requires careful process planning; inconsistent datums can cause dimensional deviation

- Adds an extra setup, increasing process management complexity

3. Overall Benefits of Coordinated Multi-Axis and 3-Axis CNC Machining

When properly planned, this coordinated approach delivers:

- Cost optimization by assigning high-material-removal tasks to 3-axis machines and precision work to multi-axis machines

- Higher productivity through reduced idle time on multi-axis equipment

- Balanced accuracy control, with critical features handled by multi-axis machining

- Greater manufacturing flexibility, suitable for prototyping, low-volume, and medium-volume production

4. When Coordinated Machining Is Not Recommended

A single multi-axis CNC machining approach may be preferable when:

- Extremely tight coaxiality or positional relationships must be maintained

- Nearly all features involve complex multi-surface geometry

- Re-clamping cannot guarantee repeatable positioning accuracy

Multi-axis CNC machining and 3-axis CNC machining are complementary, not competing processes.

By combining “3-axis rough machining + multi-axis finishing” or “multi-axis primary machining + 3-axis single-face refinement,” manufacturers can reduce cost, improve efficiency, and maintain precision while increasing production flexibility.

How to Choose a Multi Axis CNC Machining Supplier

Selecting the right supplier is critical for project success.

Key evaluation criteria include:

- Proven multi axis CNC machining experience

- Advanced CAM and programming capability

- Comprehensive inspection equipment

- Stable quality management systems

- Clear communication and documentation

A qualified supplier reduces technical and delivery risk.

Final Thoughts on Multi Axis CNC Machining

Multi axis CNC machining enables manufacturers to produce complex, high-precision parts with greater efficiency and consistency. By understanding materials, process control, inspection requirements, and operational risks, buyers can fully leverage the advantages of multi axis machining.

If you are sourcing reliable multi axis CNC machining services for metal or plastic parts, Weldo Machining provides advanced multi axis CNC capabilities, strict quality control, and flexible production solutions. Contact Weldo Machining today to discuss your requirements and receive a competitive quotation.