Understanding the peek cnc machining price is critical for industries that rely on high-performance polymer components with exceptional strength, heat resistance, and dimensional stability. PEEK (polyether ether ketone) is one of the most advanced engineering plastics used today, and machining it requires specialized tools, high heat-tolerance techniques, and precision cutting strategies. In this article, we explain what determines PEEK machining cost, available material grades, key industries, and common accessories used in PEEK components.

What Determines PEEK CNC Machining Price?

PEEK is significantly harder and more heat-resistant than standard plastics, which increases machining difficulty. The peek cnc machining price depends on multiple engineering factors that influence tool wear, cycle time, and machining quality.

1. PEEK Material Grade

Different grades influence cost due to mechanical strength, additives, and performance.

Virgin PEEK

- Pure PEEK polymer

- High strength and stability

- Excellent for medical and aerospace use

Glass-Filled PEEK (GF30)

- Reinforced with glass fiber

- Higher stiffness

- Used for load-bearing components

Carbon-Filled PEEK (CF30)

- Superior strength, lower friction

- Excellent for wear-resistant applications

These grades influence tool wear and directly affect peek cnc machining price.

2. Part Complexity & Tolerances

PEEK parts with:

- Thin walls

- Multiple undercuts

- Tight tolerances (±0.01–0.02 mm)

require specialized cnc machining peek services, increasing the final price.

3. Heat Management During Machining

PEEK softens at high temperatures. Machining requires:

- Coolant strategies

- Slow feed rates

- Specialized carbide tooling

These factors add to machining time and cost.

4. Surface Finishing Requirements

Common finishes that affect peek cnc machining price include:

- Polishing

- Deburring

- Precision grinding

- Dimensional inspection

5. Production Volume

Prototype orders cost more per piece, while wholesale peek cnc machining significantly reduces unit cost.

Advantages of PEEK in CNC Machining Applications

PEEK is used in extreme environments where traditional plastics fail. Its exceptional physical properties justify the higher peek cnc machining price.

Mechanical Advantages

- High tensile strength

- Excellent impact resistance

- Low friction coefficient

Thermal Performance

- Continuous use temperature up to 260°C

- Exceptional heat-resistant stability

Chemical & Corrosion Resistance

- Resistant to fuels, acids, and solvents

- Ideal for harsh industrial environments

These advantages explain why custom peek cnc machining is widely adopted across high-tech industries.

Applications of PEEK CNC Machining Across Industries

A professional peek material cnc machining service supplies PEEK components used in demanding markets.

Aerospace & Defense

Typical Parts

- Insulation components

- High-temperature brackets

- Aircraft engine connectors

PEEK is valued for its light weight and heat resistance.

Medical & Dental Industry

Typical Parts

- Surgical tool components

- Dental inserts

- Imaging equipment parts

Medical PEEK must meet biocompatibility standards.

Automotive & Electric Vehicles

Typical Parts

- High-voltage insulators

- Bearing cages

- Transmission guide components

PEEK replaces metal in high-temp automotive zones.

Semiconductor & Electronics

Typical Parts

- Wafer handling parts

- High-precision insulators

- Chip manufacturing fixtures

Stability at high temperatures is essential here.

Oil & Gas Industry

Typical Parts

- Valve components

- High-pressure seals

- Downhole tool parts

Excellent chemical resistance justifies the higher peek cnc machining price in this sector.

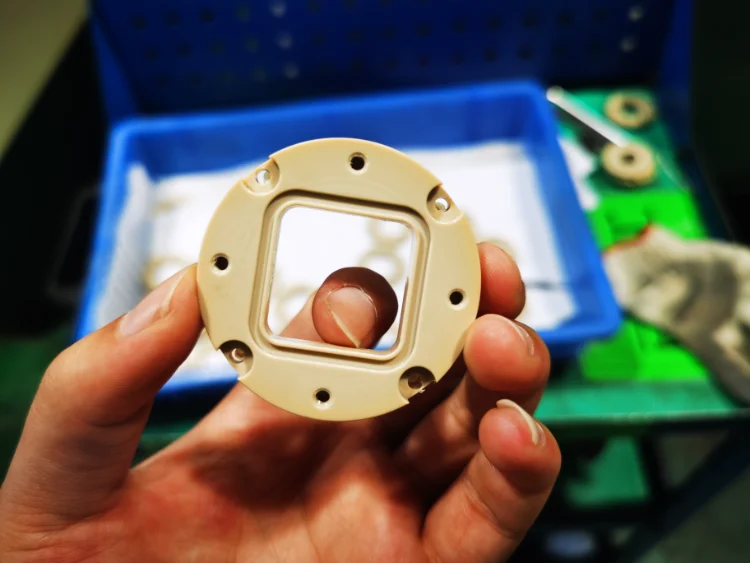

Common Accessories and Features in PEEK CNC Components

PEEK components often include additional accessories that enhance structural integrity and function.

1. Threaded Inserts

Purpose

- Adds metal-reinforced threading

- Improves durability in repeated assembly

2. Sealing Rings & O-Ring Grooves

Purpose

- Ensures leak-proof performance

- Used for pumps, valves, and compressors

3. Precision Bushings

Purpose

- Reduces friction

- Provides smooth motion in mechanical assemblies

4. Mounting Holes & Alignment Slots

Purpose

- Enables accurate positioning during installation

- Frequent in automation and robotics parts

5. Wear-Resistant Coatings (Optional)

Purpose

- Enhances longevity

- Provides additional lubrication in moving systems

Accessories improve usability and increase the engineering value of PEEK components.

CNC Machining Processes Used for PEEK Components

Because PEEK is tough and thermally sensitive, the machining workflow affects final part quality and cost.

CNC Milling

Used for:

- Precision slots

- Complex 3D shapes

- Tight-tolerance surfaces

CNC Turning

Used for:

- Rings

- Bearings

- Cylindrical housings

Drilling & Tapping

Used for:

- Mounting holes

- Threaded connections

Surface Polishing & Grinding

Used for:

- Smooth sealing surfaces

- High-precision functional parts

These processes collectively determine the final peek cnc machining price.

Estimated PEEK CNC Machining Price Ranges

| PEEK Component Type | Price Range |

|---|---|

| Small prototype part | $20–$80 each |

| Medium-complexity bracket | $80–$200 each |

| High-precision aerospace part | $200–$500+ |

| Large industrial components | $400–$1,200+ |

Prices vary based on tolerance, complexity, grade, and order quantity.

Request PEEK CNC Machining Price — Contact Weldo Machining

For high-accuracy engineering components, choosing the right machining partner ensures reliable performance and competitive peek cnc machining price. As a professional supplier of PEEK machining solutions, Weldo Machining provides advanced CNC milling, turning, tolerance inspection, and small-to-large volume production.

Contact us today for detailed quotations and engineering support for your PEEK CNC machining project.

FAQ of peek cnc machining price

Why is PEEK CNC machining more expensive than regular plastics?

PEEK is heat-resistant, mechanically strong, and harder to cut, requiring specialized tools and slow machining speeds.

Which PEEK grades are best for CNC machining?

Virgin PEEK is ideal for precision parts;

while glass-filled and carbon-filled grades offer higher strength for industrial applications.It is more difficult to process, slower to process, and more expensive to process.

Can PEEK parts achieve tight tolerances?

Yes—PEEK can be machined to ±0.01–0.02 mm when processed with controlled heat management.