PMMA CNC machining

Overview:

We professionally provide PMMA CNC machining services with exceptional precision, controlling tolerances to within 0.002 inches, meeting your stringent requirements for high-precision parts. Please feel free to contact us for a quote if you have any related machining needs!

Tolerance: Up to 0.002 inch

MOQ : Prototype welcomed

Price: 10-100 usd/PCs

Delivery time: 1-5 days

Application: Aerospace,automotive etc.

What is Pmma cnc machining ?

Pmma CNC machining is a process of molding and precision machining of high-performance plastic pmma using CNC machine tools. It can produce complex, high-precision parts with small tolerances, and is suitable for demanding industries such as aerospace, medical, and automotive.

Types of pmma for cnc machining

Transparent PMMA: With a light transmittance exceeding 92%, approaching that of glass, its smooth surface is easy to polish, making it suitable for high-precision optical and lighting components.

Used in lenses, lampshades, and medical equipment, meeting both transparency and surface quality requirements.

Colored Transparent PMMA: Adding pigments achieves semi-transparent coloring with uniform color, balancing light transmittance and decorative appeal.

Suitable for colored signage, light boxes, and consumer electronics accessories; the first choice for personalized designs.

Pearl/Embossed PMMA: Adding pearlescent or embossed textures to the surface enhances visual effects, breaking through the limitations of traditional molds.

Used for irregularly shaped lampshades and decorative panels, enabling customized processing of complex curved surfaces.

Weather-Resistant PMMA: Containing UV-resistant components, it does not fade with long-term outdoor use and exhibits excellent aging resistance.

Primarily used for outdoor signage and traffic signs, reducing maintenance costs.

Medical-Grade PMMA: Meets biocompatibility standards, is non-toxic, and resistant to high-temperature sterilization, ensuring medical safety.

Used in artificial joints, dental implants, and laboratory chips, combining precision and safety.

Process of cnc machining for pmma material

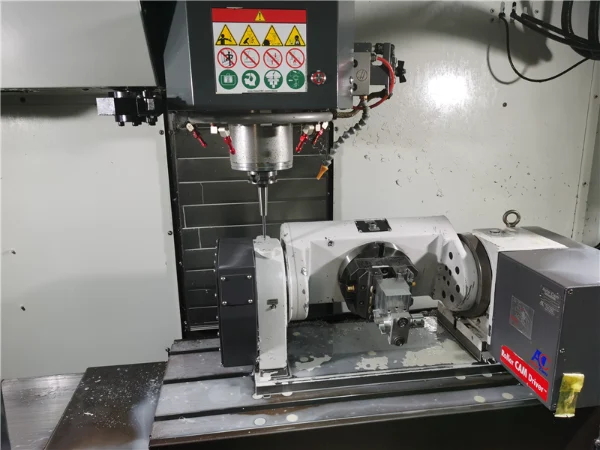

Pmma material can be used to manufacture high-precision parts that meet customer needs through CNC 3-axis, 4-axis, and 5-axis machining, turning, grinding, and tapping processes.

Surface finish for cnc machined pmma parts

Based on over 15 years of CNC machining experience, we have compiled the following list of surface finish processes used for various precision-machined parts made from pmma material.

| Surface Finish | Description | Typical Applications |

|---|---|---|

| As-Machined | Machined surface with visible tool marks; suitable for functional or internal parts where appearance is not critical. | Functional components, internal structures |

| Mechanical Polishing | Multi-step mechanical polishing removes tool marks and improves surface smoothness and transparency. | Transparent parts, display components |

| Flame Polishing | High-temperature flame briefly melts the surface to achieve high gloss and optical clarity. | Optical parts, light covers, edges |

| Diamond Polishing | Precision polishing using diamond tools to achieve optical-grade surface quality. | High-end optical applications |

| Sandblasting | Creates a frosted or matte surface, reducing glare and diffusing light. | Light diffusers, decorative panels |

| Painting / Spray Coating | Applies color or protective coatings to the PMMA surface. | Decorative or branded parts |

| Hard Coating (Optional) | Transparent protective coating to improve scratch and wear resistance. | Wear-resistant surfaces |

| Chamfering | CNC chamfering removes sharp edges and corners to improve safety, assembly fit, and appearance. | Edges, holes, assembly interfaces |

| Filleting / Edge Rounding | CNC edge rounding creates smooth radiused edges to reduce stress concentration and improve handling and aesthetics. | Edges, corners, stress-sensitive areas |

Advantage of cnc machining pmma parts

High light transmittance: Over 92% light transmittance, close to that of glass, suitable for optical and display accessories.

Stable precision: CNC machining achieves micron-level precision, resulting in strong dimensional stability and resistance to deformation.

Weather and UV resistant: Does not discolor with long-term outdoor use, exhibiting excellent UV resistance.

Lightweight and robust: Weighs only half as much as glass, with moderate strength, suitable for lightweight applications.

Easy to process and shape: Convenient for cutting, engraving, and polishing; simple post-processing and high efficiency.

Application of cnc machining pmma part

Optics: Camera lenses, microscope lenses, fiber optic connectors, etc., utilize the high transmittance and low birefringence of PMMA.

Lighting Industry: LED lamp covers, automotive taillight diffusers, use CNC machining to achieve complex light-transmitting structures and improve light uniformity.

Medical Equipment: Test tubes, petri dishes, surgical instrument handles, etc., must meet biocompatibility and transparency requirements.

Consumer Electronics: Smartphone screen protectors, VR glasses lenses, combine CNC machining and coating technology to achieve anti-reflective and scratch-resistant functions.

Advertising Displays: Acrylic signs, light boxes, display stands, use CNC engraving of logos or patterns to enhance visual appeal.

FAQ of Pmma cnc machining

How to solve cracking/chipping issues in PMMA CNC machining?

Tool selection: Use sharp carbide or diamond-coated tools to reduce cutting heat and stress.

Cutting parameters: Reduce feed rate (0.05-0.2mm/tooth), depth of cut ≤ 50% of tool diameter.

Cooling method: Prioritize compressed air cooling to avoid stress cracking caused by residual water-based coolant.

Fixing method: Vacuum adsorption for thin plates, mechanical clamping for thick plates to reduce vibration.

What are the costs and influencing factors of PMMA CNC machining?

Material cost: Thick plates/large-sized materials are more expensive.

Machining complexity: Complex structures require multiple clamping or tool changes, increasing machining time.

Precision requirements: High precision (±0.01mm) requires precision equipment, increasing costs.

Post-processing: Polishing, annealing, and other processes incur additional charges.

What are the advantages of PMMA CNC machining compared to 3D printing/injection molding?

Precision: CNC reaches micron-level precision, producing smooth, burr-free surfaces, suitable for optical/medical applications; 3D printing produces layer textures, while injection molding relies on mold precision. Cost: CNC machining for small to medium batches has no mold costs and high material utilization; injection molding is suitable for large-scale production but mold costs are high; 3D printing materials are expensive.

Process Adaptability: CNC machining directly processes sheet/block materials, allowing for one-time molding of complex structures (such as deep cavities and thin walls); 3D printing requires support, while injection molding is limited by mold parting.

Performance: CNC machining has no interlayer defects and has better impact resistance than 3D printing; injection molded parts may require annealing to relieve internal stress.

Applications: CNC machining dominates high-end optics, medical, and aerospace; 3D printing is used for rapid prototyping; injection molding is used for mass-produced products such as consumer electronics.