Selecting a reliable POM Connecting Rods manufacturer is crucial when producing lightweight, wear-resistant, and dimensionally stable components for mechanical systems, automation equipment, and precision machinery. POM (polyoxymethylene), also known as acetal or Delrin®, is widely used for plastic connecting rods thanks to its excellent strength-to-weight ratio, low friction, and outstanding machinability.

This article explains why POM is ideal for connecting rod applications, how CNC machining ensures accuracy, what industries rely on POM connecting rods, and how to choose a professional POM Connecting Rods manufacturer for both prototypes and mass production.

Why POM Is Ideal for Connecting Rod Applications

POM is an engineering thermoplastic designed for mechanical performance. Compared with metals or other plastics, it offers a unique balance of strength, stiffness, and low friction.

Key Material Properties of POM

- High mechanical strength and rigidity

- Excellent wear resistance

- Low coefficient of friction

- Good fatigue resistance

- Low moisture absorption

- Dimensional stability under load

Because of these properties, a POM Connecting Rods manufacturer can produce precise, reliable components without lubrication in many applications.

Advantages of POM Connecting Rods vs Metal Rods

Lightweight Design

POM connecting rods are significantly lighter than steel or aluminum alternatives, reducing inertia in moving assemblies.

Self-Lubricating Performance

POM naturally reduces friction, eliminating the need for oil or grease in many mechanical systems.

Corrosion and Chemical Resistance

Unlike metal rods, POM does not rust and performs well in humid or chemically aggressive environments.

Low Noise and Vibration

Plastic connecting rods absorb vibration, improving system stability and operational comfort.

For these reasons, manufacturers increasingly rely on a specialized POM Connecting Rods manufacturer instead of metal suppliers.

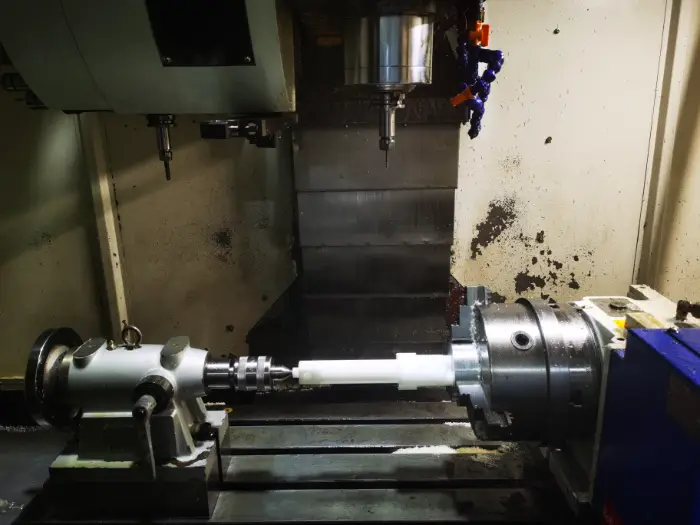

CNC Machining Process for POM Connecting Rods

A professional POM Connecting Rods manufacturer typically uses CNC machining to achieve consistent quality and tight tolerances.

CNC Milling and Turning

- High-speed CNC milling for complex profiles

- Precision CNC turning for shaft and pin features

- Clean chip formation with minimal heat buildup

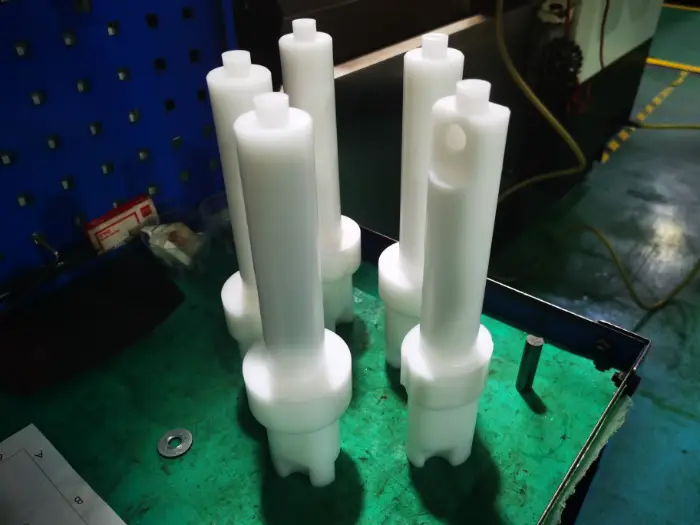

Tolerances and Accuracy

- Standard tolerance: ±0.05 mm

- High-precision zones: ±0.01–0.02 mm

Surface Finish Quality

Smooth surface finishes reduce friction and extend service life in dynamic applications.

POM Material Grades Used by POM Connecting Rods Manufacturers

POM Homopolymer (Delrin®)

- Higher strength and stiffness

- Excellent fatigue resistance

- Ideal for high-load connecting rods

POM Copolymer

- Better chemical resistance

- Improved thermal stability

- Suitable for fluid-contact environments

Filled POM Grades

- Glass-fiber-reinforced POM for higher rigidity

- PTFE-filled POM for ultra-low friction

An experienced POM Connecting Rods manufacturer selects the right grade based on load, speed, temperature, and environment.

Applications of POM Connecting Rods

Industrial Automation

- Linear motion systems

- Pneumatic and actuator linkages

Automotive & Mobility Systems

- Small actuator mechanisms

- Adjustment and control linkages

Medical and Laboratory Equipment

- Motion arms in diagnostic devices

- Low-noise internal mechanisms

Consumer and Precision Machinery

- Mechanical drives

- Wear-resistant linkage components

In these applications, a qualified POM Connecting Rods manufacturer ensures consistent performance and repeatability.

Quality Control and Inspection

A professional manufacturer applies strict quality controls to every batch of POM connecting rods:

Dimensional Inspection

- CMM and optical measurement

- In-process inspection

Material Verification

- Certified POM material sources

- Batch traceability

Functional Testing

- Assembly and motion testing

- Wear and fatigue evaluation

These steps distinguish a high-quality POM Connecting Rods manufacturer from a basic plastic supplier.

Cost Factors in POM Connecting Rod Manufacturing

Material Cost

POM is more expensive than basic plastics but far cheaper than machined metal rods.

Machining Time

Complex geometry and tight tolerances increase CNC time.

Production Volume

Batch production significantly reduces per-unit cost.

Design Optimization

Uniform wall thickness and simplified geometry reduce machining cost.

Working with an experienced POM Connecting Rods manufacturer helps optimize cost without sacrificing performance.

How to Choose the Right POM Connecting Rods Manufacturer

CNC Machining Capability

3-axis to 5-axis CNC equipment ensures geometric flexibility.

Engineering Support

DFM (Design for Manufacturability) capability reduces errors and lead time.

Experience with POM Materials

Understanding cutting behavior, thermal control, and fixturing is essential.

Scalable Production

The best suppliers support both prototyping and mass production.

Conclusion

A professional POM Connecting Rods manufacturer plays a key role in delivering lightweight, durable, and low-friction components for modern mechanical systems. With the right POM material grade, advanced CNC machining, and strict quality control, POM connecting rods provide an efficient alternative to metal rods in many applications. Choosing an experienced manufacturer ensures long-term reliability, cost efficiency, and consistent performance.

If you want to know more details of cnc machining pom connecting rods,you can feel free to contact with us Weldo machining later